Freeform surfaces can be machined with high accuracy in a shorter amount of time

POINT 01

- 5-axis machining center with high accuracy and high machining capabilities

-

- Trunnion table supported at both ends for a highly rigid structure, enabling highly accurate indexing and high-speed operation

- Its high machining capacity enables highly efficient machining

- Face milling: 504 cm3/min (S45C)

- End milling: 672 cm3/min (S45C)

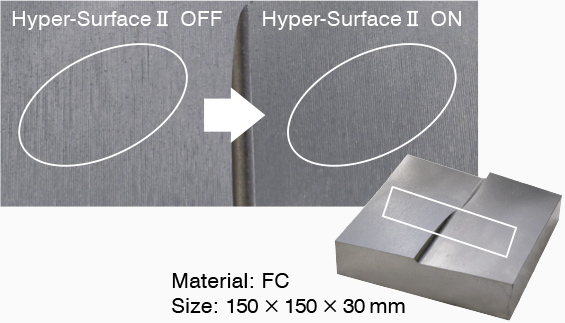

Freeform surface machining

POINT 02

- Hyper-Surface Ⅱ improves the performance of freeform surface machining

-

- There is no need to modify machining data. Ridgelines and uneven surface edges are reduced, the machined surface quality is improved, and hand-polishing time is eliminated.

- Hyper-Surface II automatically compensates for fluctuations in the CAM machining data, and for positional misalignment between edges and adjacent cutter paths, while maintaining the required shape accuracy

- Vibration is suppressed without slowing down at corners, shortening the machining time and improving surface quality

New solution proposal using additive manufacturing

Next-Generation Super Multitasking Machine LASER EX

- 5-axis machining and additive manufacturing are integrated into one machine, reducing expensive material costs

-

- The amount of cutting is reduced through additive manufacturing of projections. Metals different from the base material can also be laminated, which can reduce material costs.

- With turning + milling + additive manufacturing, everything from additive manufacturing to finishing can be performed without setup changes

Additive manufacturing of projections