- HOME

- Technology & Solutions Case Studies

- KINREI MACHINERY CO., LTD.

Case Studies

—Why Okuma was chosen

The top niche global manufacturer of bunchers chose the Multitasking Machine + Built-in Robot—capable of process integration, automation, and space savings

KINREI MACHINERY CO., LTD.

- Industry

- Development and manufacturing of production machinery for electric wires

Challenges at the manufacturing site

We wanted to reduce lead time and save space by finding a way to integrate the multiple manufacturing processes required to machine core components, which were conventionally done using a lathe and an external robot.

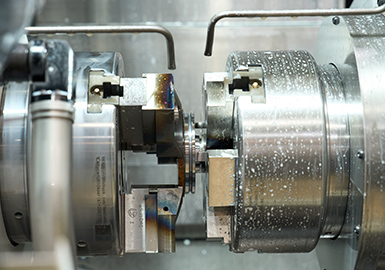

All core components of the bunchers are manufactured in-house. One such component is the guide wheel, a pulley used to feed metal wire. Its V-groove must be machined with high precision in order to smoothly feed ultra-fine metal wires—which are thinner than a human hair—at high speeds.

Until now, machining the guide wheel required five steps: two performed by an automated system consisting of an NC lathe and external robot, followed by drilling and finishing processes. Setup changes were both labor and time intensive, while the safety fences consumed valuable floor space. Reducing lead time and achieving space efficiency had been ongoing challenges.

The Okuma machine selected to solve these challenges

Decisive factor for installation

MULTUS B300Ⅱ ARMROID, which is equipped with a built-in robot,

enables process integration and automation

In addition, it eliminates the need for safety fences, achieving both space efficiency and a high level of operational safety

We have used many Okuma machines. We actually already have two multitasking machines which we have been using for some time now: the MULTUS B300 and the MULTUS U4000. When we consulted with Okuma about our need for high precision machining to achieve the high concetricity required to manufacture our guide wheels, they proposed the MULTUS B300Ⅱ ARMROID. This machine would allow space saving, automation, and process integration.

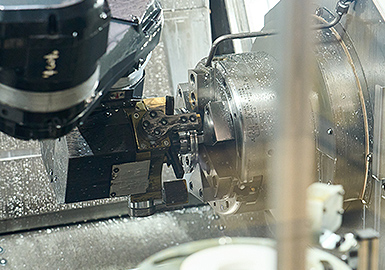

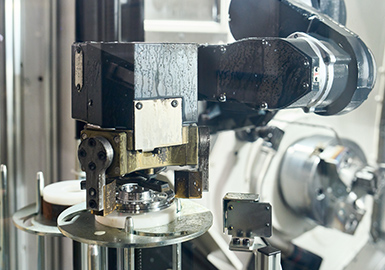

We believed that this proposal would allow us to consolidate several machining processes, which required multiple machines and material handling equipment, into a single machine. This would result in significant lead time reduction and space saving. What made the MULTUS B300Ⅱ ARMROID especially attractive was its built-in robot arm. Compared to our previous methods of machining, this machine would allow us to increase productivity while only requiring minimum space to install the machine and mobile workpiece stocker. In addition, the ability to ensure operator safety without installing safety fences made us feel this machine would be the perfect solution to the challenges we were facing.

On the other hand, there were two concerns. We were concerned that the combination of a sub spindle and a moving turret would increase the risk of machine collisions. However, this risk was solved with the collision avoidance system. The other concern was whether the machining accuracy required for the V-groove of guide wheels could be secured. Trial cuts revealed that chips scattered within the machining chamber negatively affected the groove’s machining quality. In response, we collaborated with Okuma to develop a solution. Okuma modified the jaw shape, while we revised some of the guide wheel’s machining process. These adjustments successfully reduced the effects caused by chip scattering and allowed us to overcome this problem. (Takahiro Chiba)

Takeshi Suzuki

Takahiro Chiba

Effectiveness of machine after installation

Lead time has been significantly shortened by merging five processes (which were done across two machines) into two processes (that can be done on one machine)

Previously, machining of guide wheels required five separate processes, involving considerable time and effort for attaching, detaching, and transferring workpieces during each setup change. With the introduction of the MULTUS B300Ⅱ ARMROID, operators simply load the workpieces into the mobile work stocker (a 10-station elevating multi-level worktable) attached to the machine. From there, the machine handles the entire operation, completing everthing in just two processes. As a result, lead time has been drastically reduced and the extra time can now be used for program creation and setup for the next machining task. This has contributed to improving overall productivity. (Production division Manufacturing section Eiji Oikawa)

Checking for interferences using the collision avoidance system after program is created enables safe and automatic operation, even if it is a part being machined for the first time.

The machining chamber contains two spindles (main and sub), a turret, a robot, and various structural components, making it difficult to track all movements and perform comprehensive interference checks. However, by using the collision avoidance system after creating the program, interference can be checked visually and allows automatic operation to be done with confidence. In addition, jaw shapes can be defined as material models. This allows for interference checks (of the soft jaw machining process) to be done using 3D models. This contributes to improved operational efficiency.

Currently, the MULTUS B300Ⅱ ARMROID is operated by an experienced team leader. By attending Okuma’s NC school and experimenting with a variety of machining conditions, he is now able to machine various parts. Not limited to only guide wheels.

Impressions after installation

Being able to easily switch from a standalone machine to a robot machining cell has become a reality

To improve productivity with a limited number of employees, we have a vision of performing short-cycle turning and small-lot machining operations manually during the day, while using the MULTUS B300Ⅱ ARMROID for unmanned overnight operation of medium-lot complex machining tasks that require longer cycle times.

The key to successful unmanned overnight operation lies in the efficient handling of discharged chips. At the same time as installing the MULTUS B300Ⅱ ARMROID, we installed a system that crushes chips and compresses them into pellets to reduce their volume. We are currently evaluating the possibilities of extended unmanned operation by connecting this system with our machines. We are confident that such attempts are only possible thanks to the capabilities of the MULTUS B300Ⅱ ARMROID.

Going forward, we plan to utilize features such as AI Machine Diagnosis Function, which predicts and detects spindle and feed axis failures, in order to expand machine utilization and further improve productivity. (President Takeshi Suzuki)

Customer Information

KINREI MACHINERY CO., LTD.

(Oshu City, Iwate Prefecture)

- Website

- https://kinrei.co.jp/

In 1934, Kinrei Machinery was founded Tokyo's Minato Ward and developed electric wire stranding machines. Since then, the company has expanded its lineup as a manufacturer of wire stranding machines (bunchers), offering a wide variety of models. In 1992, anticipating the company's future growth, Kinrei built its Iwate Plant in Oshu City and later transferred its head office there. Kinrei’s bunchers are essential production equipment for cables and wire harnesses used in automobiles, aircraft, mobile devices, and medical equipment. They are supplied to clients in over 20 countries, including overseas markets.

The company holds the world’s No. 1 market share in fine wire and winding wire bunchers, with 70% of its sales generated from overseas markets.