PRODUCTS

Okuma built-in robots bring more breakthrough innovations

Being simple

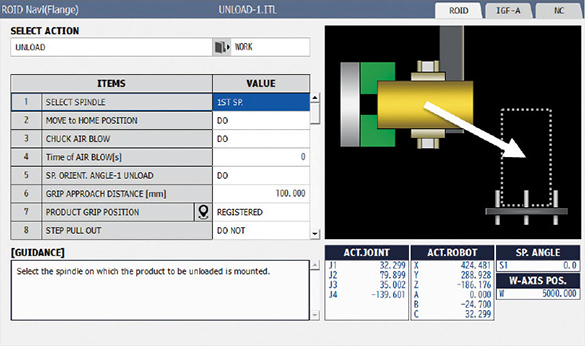

The ROID Navi was developed specifically for machine tool operators, eliminating the need for complex robot programming.

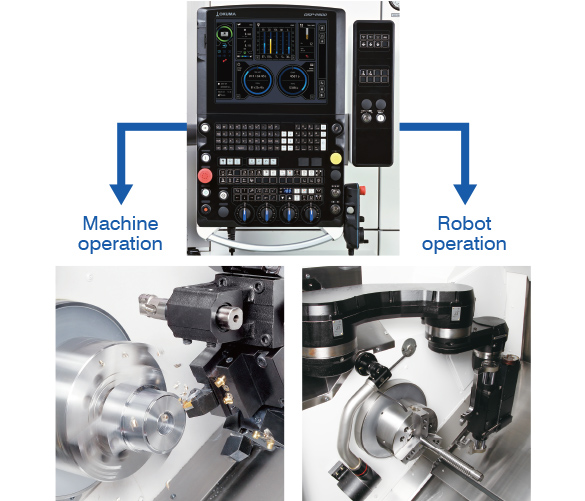

Easy machine tool or robot operation by any operator

Okuma's intelligent machine tool CNC enables real time gesture control of both the robot and machine tool.

ROID Navi EZ Operating Tool

The robot's motion program automatically generates an optimal motion path that does not collide, simply by displaying the input start and end points and the parameters according to guidance prompts.

Even beginners in robotics can learn the ropes to operate from day one.

Ease of use

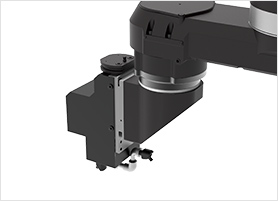

With the machine's pulse handle, robot operations can be performed easily with almost surgical precision.

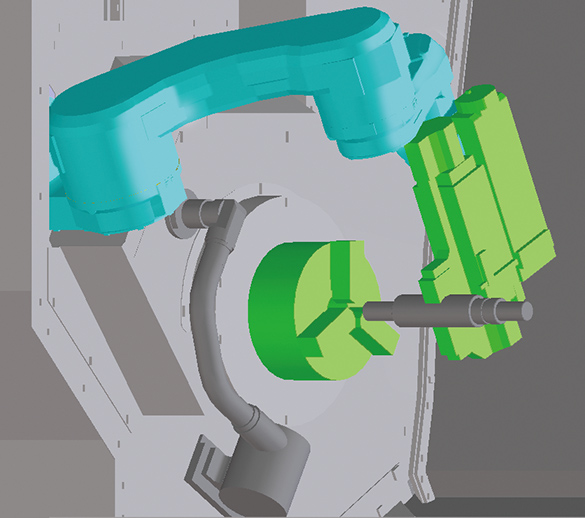

Pre-op 3D simulation to confirm robot collision avoidance.

A multifaceted technician

Letting robots consistently perform better than skilled machinists on routine, repetitive tasks.

Achieve high-level processing support possible only with built-in robots

Providing in-process support in the machining chamber that is impossible with conventional robots.

Changing the way we work

Operators work in the day and the robots work at night. Striving for zero overtime, and the coexistence of humans and robots.

Improving production efficiency through human and robot work sharing

- Easily switch from a single machine to a robot automated cell simply by adding a mobile workpiece stocker.

- For example, the robot can be on standby during the day while the operator handles small batches of part load/unload and other flexible jobs, and then automatic operations done by the robot can be done at night.

Various configurations available to meet production needs

ARMROID's lineup of applications

![LB3000 EX Ⅲ ARMROID [CNC Lathe + Built-in Robot]](/english/product/automation/images/armroid/p_product06.jpg)

LB3000 EX Ⅲ ARMROID [CNC Lathe + Built-in Robot]

Click here for information about the

1-saddle CNC lathe LB3000 EX Ⅲ

![MULTUS B250Ⅱ / B300Ⅱ ARMROID [Multitasking Machine + Built-in Robot]](/english/product/automation/images/armroid/p_product07.jpg)

Photo shows the MULTUS B250Ⅱ ARMROID

MULTUS B250Ⅱ / B300Ⅱ ARMROID [Multitasking Machine + Built-in Robot]

Click here for information about the

multitasking machine MULTUS B250 Ⅱ

End effectors

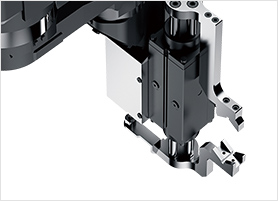

- Long stroke

2-finger parallel gripper - Shaft part loading.

- 3-finger gripper

- Flange part loading.

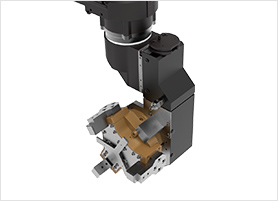

- Workpiece support rollers

- Workpiece support during machining, also suppresses chatter

- Mixed blasting nozzles

- Coolant and air blasts remove chips and clean the machining chamber while cutting.

Workpiece stockers

- General-purpose rail (2-shelf)

- For shaft workpiece applications

- Pitch feed part conveyor (18/36 stations)

- For shaft workpiece applications

- Stackable parts elevating worktable (6/10 stations)

- Flange workpiece applications

Specifications

| Machine Model | LB3000 EX Ⅲ ARMROID |

MULTUS B250Ⅱ ARMROID |

MULTUS B300Ⅱ ARMROID |

|---|---|---|---|

| Machine Specification | Turning/Multitasking DBC: 500 Spindle: Standard / Big-Bore / Standard high power Tailstock: AVL / NA / Sub-spindle Y-axis control: AVL / NA |

DBC: 750 Spindle: Std / Std high power Tailstock: AVL / NA / Opp spdl |

DBC: 900 Spindle: Standard / Big-Bore / Standard high power Tailstock: AVL / NA / Opp spdl |

| ARMROID Type | A201 | ||

| ROID Navi | EZ Operating Tool | ||

| End effector max carrying load | Long stroke 2-finger parallel gripper (shafts) 10 kg |

||