- HOME

- Technology & Solutions Premium Solutions

- B-axis Turning

Technology & Solutions Premium Solutions

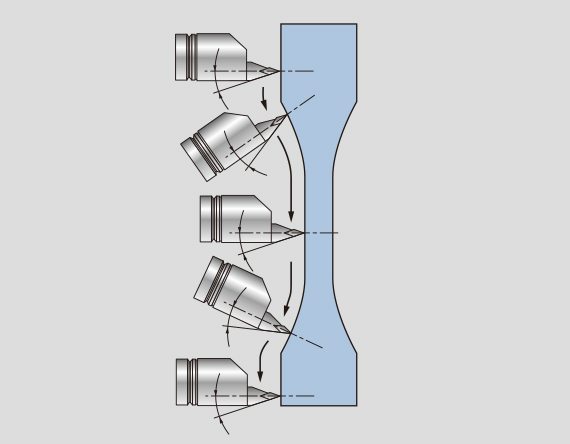

Efficient curved-surface turning

Simultaneously controlled X, Z and B axes of a multitasking

machine efficiently turns curved surfaces.

- Production floor issues

- Ridges remain after curved

surface machining -

- ・Tools must be changed to find the best tool to cut a curve.

- ・Changing a tool part way into a curve causes a ridge.

- Ridges remain after curved

- User benefits

- Ridges gone from curved

surface applications -

- ・Tool angles are always just right, so jobs without tool changes allow curved surface applications.

- ・When cutting a curve, machining can always be done at the best tool angle, to eliminate ridges and get uniform quality.

- Ridges gone from curved

Tilted B-axis cutting for curves improves efficiency

When turning a curved surface, tool changes become necessary to work the shape with a fixed (non-universal) B axis head. Here in B-axis turning, the B-axis angle can be controlled to the curve contour, so applications are possible with one tool.