- HOME

- Technology & Solutions Premium Solutions

- C-axis Torque Skip

Technology & Solutions Premium Solutions

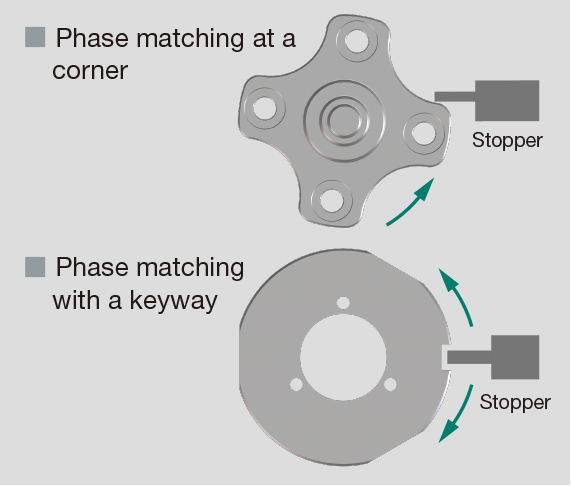

Easy and automatic phase matching

Here is how to get C-axis zero offsets: by mounting a stopper on the turret,

and having it contact a keyway or notch, to read the C-axis torque fluctuations.

- Production floor issues

- Fixtures and gauging required

blank material phase matching -

- ・A cutting reference for a phase direction requires phase matching for each workpiece.

- ・Phase adjusting required when mounting blanks, causes accuracy variances per operator setup.

- ・We can’t buy expensive in-process gauging just for doing zero offsets.

- Fixtures and gauging required

- User benefits

- Easy phase setting without

measuring devices -

- ・Eliminate fixture- and operator-related mount errors.

- ・Eliminate fixture-related phase matching.

- ・Eliminate in-process gauging.

- Easy phase setting without

Auto phase settings by the stopper contacting the cutting reference

C-axis zero offsets can be set in-machine by having the stopper contact the cutting reference. When a workpiece has a keyway, reciprocating CW/CCW rotation will index the C-axis zero offset position by the load on the C axis.