- HOME

- Technology & Solutions Case Studies

- Synthemec Co., Ltd

Case Studies

—Why Okuma was chosen

Lead time for high-mix, low-volume production of ø500–ø1,000 mm parts reduced by 50%.

Machine that autonomously performs high levels of 5-axis machining

Synthemec Co., Ltd

- Industry

- Manufacturing of automatic labor-saving equipment, and contract machining of precision parts

Challenges at the manufacturing site

By installing a 5-axis machining center, we aimed to increase our in-house production ratio to reduce the cost and time associated with outsourcing work.

We do design, parts machining, assembly, and development of controls for the automatic labor-saving equipment we produce. We have established an integrated process. The equipment we produce comes in a variety of sizes, and its components are manufactured in high-mix, low-volume quantities.For machining parts in the ø500–ø1,000 mm range, we did not have a machining center with the appropriate table size. As a result, we had to split the process between turning and machining, and sometimes outsourced part of the work. A 5-axis machining center suitable for this size range would not only shorten lead time through process integration, but also reduce the cost and time required for outsourcing.

In addition, being able to design equipment under the premise that components will be machined in-house would bring significant advantages to insourcing.

The Okuma machine selected to solve these challenges

Decisive factor for installation

We selected the MU-8000V-L (with turning specification) for its ability to do both heavy-duty cutting and high-accuracy machining, as well as its features that improve productivity even if highly skilled operators are absent.

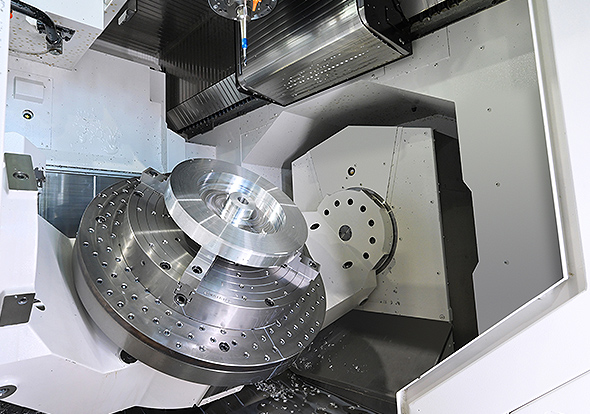

Taking the neccessary machining range into account, we chose the MU-8000V-L. The machine's rigidity enables both heavy-duty cutting and high-accuracy machining. Our main goal was to install a machine that could manufacture workpieces in the ø500 to ø1,000 mm size range, where there had been difficulties at times for insourcing. In addition to covering this size range, a major factor in choosing the MU-8000V-L was its turning capability that is equal to that of an Okuma lathe.

Our existing MU-500V III is a 5-axis machining center capable of machining workpieces up to ø700 mm. By adding the MU-8000V-L, we can significantly expand our machining range, which will contribute in providing higher-value contracted machining as well as improving the production of automatic labor-saving equipment.

We were also drawn to features such as the 5-Axis Auto Tuning System, which allows geometric errors in 5-axis machining centers to be corrected easily and thereby improving machining accuracy. Another goal was to create an environment that made it easier for younger operators to take on 5-axis machining. (Shuhei Matsumoto)

Effectiveness of machine after installation

Lead time reduced by approximately 50% through process integration

Previously, ø500–ø1,000mm-sized parts were first turned on an NC lathe or a large multitasking machine before being machined on a machining center. With the installation of the MU-8000V-L, both turning and milling can be completed on the same machine. As a result—when accounting for preparation work, accuracy checks, and workpiece transfer associated with setup changes—we were able to reduce production lead time by approximately 50%. Larger machines require significantly more effort for setup. The introduction of the MU-8000V-L has greatly improved workability and significantly reduced outsourcing costs for parts of this size range.

High accuracy consistently maintained with minimal effort with Thermo-Friendly Concept

Correction work and calculations for accuracy management are no longer necessary

In addition to heavy-duty cutting, precision machining with tight tolerance requirements is also common work for us. Before installation, we had some concerns about the machining capability of a complex 5-axis system and about the possibility of variations in accuracy occurring during long-run operations. However, after operating the MU-8000V-L, we found that its machining capability is equal to that of our existing #50 taper 3-axis machining centers. Its stability in machining accuracy is excellent, and we can clearly feel the machine’s high rigidity.

Furthermore, dimensional stability is retained at high levels thank to the Thermo-Friendly Concept —just like other Okuma machines—and requires almost no correction work even during Hokkaido’s harsh winters, when temepratures drop below zero. Previously, we had to calculate and predict dimensional changes in advance to ensure machining accuracy. Eliminating this task has allowed us to use more time on other tasks.

With the 5-Axis Auto Tuning function, you just press one button and the machine automatically adjusts accuracy for 5-axis machining.

When 5-axis machining centers are used over long operating periods, machining accuracy tends to decline. Geometric errors—caused by spindle misalignment and tilt—can develop, resulting in noticeable surface step errors during multi-sided machining. Measurement and correction must be conducted on a regular basis, but performing these tasks manually can take up to two hours per machine.

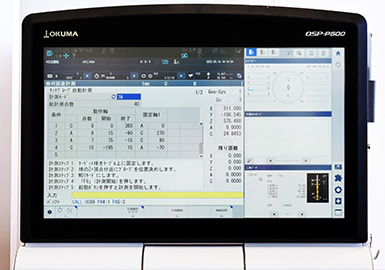

With the 5-Axis Auto Tuning Function (option), geometric errors are automatically measured and corrected with a single push of a button, completing the tuning process in about 10 minutes (in full-mode settings). Because the adjustments are highly accurate, we can use the system with confidence. It frees us from time-consuming measurement and correction tasks, and has significantly reduced machine downtime.(Yuji Kudo)

Outlook to the future

Improving work efficiency by doing external setup using Digital Twin, maximizing machine utilization rate

The MU-8000V-L is equipped with the OSP-P500, which provides a digital twin environment linking the Manufacturing Department’s office PC with the CNC of the machining center. This greatly broadens what can be prepared in advance. Tasks such as program creation, toolpath verification, and interference check can be handled by the programmer, while the machine operator can stay focused on setting up the next workpiece without stopping the machine. We expect this to further increase overall machine utilization rate. (Yuji Kudo)

Although we are still in the process of examining and validating how best to utilize Digital Twin, it enables both the office and the shop floor to monitor tool wear and accurately estimate machining time. We hope to use this capability to further improve the accuracy of process management. (Issei Asahina)

We aim to take advantage of our newly expanded machining range enabled by the MU-8000V-L to acquire new customers, and further expand our target markets.

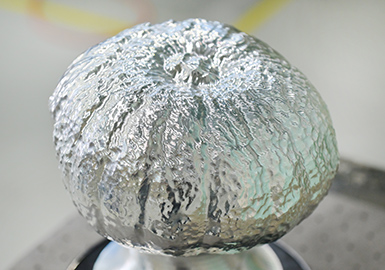

By demonstrating our enhanced machining capabilities—made possible by the MU-8000V-L—we hope to increase new inquiries and orders. We have been particularly focused the field of automatic labor-saving equipment for food processing. In June 2025, we exhibited at FOOMA JAPAN, one of the world’s largest food manufacturing exhibitions. There, we showcased newly developed equipment along with products manufactured using simultaneous 5-axis free-form surface machining to promote our technological capabilities.

Customer Information

Synthemec Co., Ltd

(Ishikari City, Hokkaido)

- Website

- https://www.synthemec.co.jp/

Founded in Otaru City in 1950 as a turning workshop. The company manufactured ship components and drain valve parts, and was incorporated in the 1980s. It established a fully integrated in-house production system for automatic labor-saving equipment*1, doing design, parts machining, assembly, and development of control systems internally. The company was renamed "Synthemec" in 2001 and relocated its production base to Ishikari City in 2008. Today, six factories work together to pursue higher quality and efficiency. Over 5,000 units of automatic labor-saving equipment have been manufactured and delivered to customers, and the company also has experience of building an entire assembly line for an automotive parts manufacturer.

*1: Automatic labor-saving equipment: Custom-made machining machines, assembly machines, measurement and inspection systems, conveying systems.