- HOME

- Technology & Solutions Okuma Smart Factory

- OSP suite

- Machine Status Logger & Cutting Status Monitor

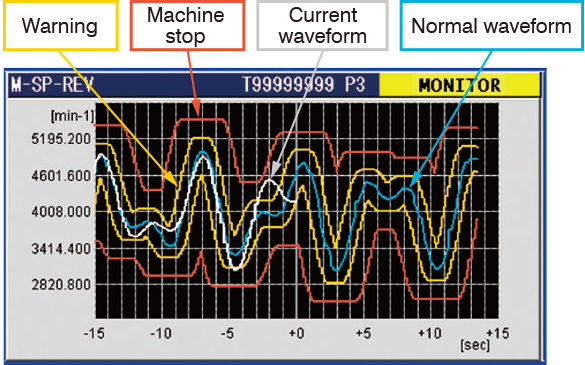

Cutting Status Monitor

This detects abnormalities in machining and executes an

automatic stop, reducing loss and also protecting the machinery

and tools.

With data during normal machining used as a reference, deviation from the reference due to a tool abnormality or the like results in a machine stop (alarm stop, slide hold, and retraction are possible). This prevents occurrence of defective pieces as well as preventing damage to the machine or tool.

User benefit

The machine can be stopped after retracting the tool from the workpiece, thereby minimizing damage to the workpiece.

* An OSP-P300A optional function.

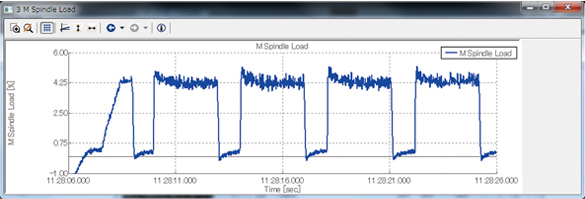

Machine Status Logger

Recording machine data such as spindle load and override

operation for use in traceability and investigation of causes when

an abnormality occurs.

This records programs and trace data that includes spindle and feed-axis load data and data from external sensors, and also records its relationship to event data such as information on operation. This makes it easy to track NC data as traceability data.

User benefit

This also records zero-point numbers, amount of zero offset, tool compensation numbers, and other operation data. This is useful when investigating defect causes.

* An OSP-P300A optional function.

![OSP suite [OSP-P300A]](/english/images/b_osp-suite.jpg)