- HOME

- Technology & Solutions Case Studies

- Shirakawa Co., Ltd

Case Studies

—Why Okuma was chosen

High-mix, low-volume production of high-accuracy large shafts

Expanding business into the seismic isolation device market with the MULTUS multitasking machine

Shirakawa Co., Ltd

- Industry

- Precision machining of large parts

Challenges at the manufacturing site

We wanted to integrate turning and milling into a single machine to shorten lead time

Our main products are ball screw shafts that come in a wide variety of sizes, as well as complex nut components with built-in balls. Ball screws convert the rotation power from the motor into a linear motion, enabling high-accuracy positioning and feeding, and supporting the fundamental performance of precision equipment. Strict machining accuracy is required, and high-mix, low-volume production with short delivery times are often demanded. Previously, the machining process was divided into separate turning and milling operations, which required significant time and effort for changeovers and setup, and often resulted in variations in machining accuracy. To address these issues, we sought to introduce a multitasking machine capable of completing all machining in a single chucking operation, thereby consolidating processes and strengthening QCD—quality, cost, and delivery.

The Okuma machine selected to solve these challenges

Decisive factor for installation

Securing dimensional accuracy by eliminating phase misalignment between thread turning and milling operations

It is extremely important that the phase alignment between thread turning and milling operations are precise during the production process. A multitasking machine eliminates concerns about phase misalignments because both operations can be performed in a single chucking operation.

We therefore considered installing the MULTUS B300II (sub-spindle specification) for machining nut components used in ball screws.

Previously, machining was performed in two separate processes—turning and milling. However, with the sub spindle, the handover of workpieces is automated and enables machining to be completed in a single cycle. This has eliminated variations in machining accuracy and has reduced lead time.

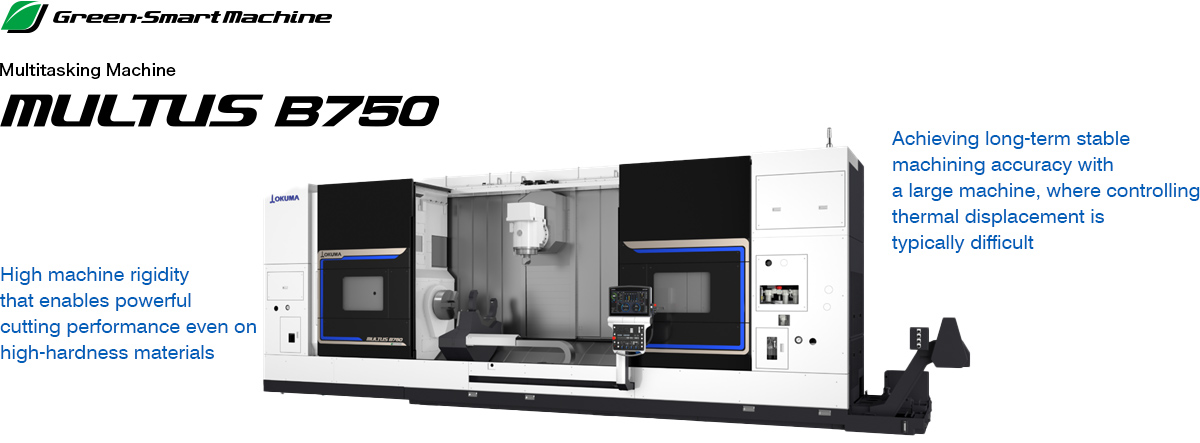

At the same time, we also considered the MULTUS B750 (with a 4,000 mm distance between centers) for machining large shafts, which are our flagship products.

A decisive factor was its capability to machine workpieces up to ø1,050 mm in diameter and 4,000 mm in length, while maintaining long-term stable machining accuracy. Thermal displacement control is typically difficult with large machines, so being able to maintain stable accuracy was very important. Combined with the machine's high rigidity that enables to cut high-hardness material with ease, we chose the MULTUS B750.

Effectiveness of machine after installation

Achieving a 100% on-time delivery rate and a defect rate of just 0.2%

We strongly emphasis QCD and pursue continuous improvement. When processes were divided across multiple machines, the machining sequence depended on whether the next machine was available for machining, making it challenging to meet customer-specified delivery dates precisely.

Installing the MULTUS made process integration possible, allowing us to accurately estimate machining time and achieve an on-time delivery rate of nearly 100%. In terms of quality, we have maintained a defect rate of 0.2% based on material cost. Supporting this achievement is our company-wide quality control system and well-organized plant environment, as well as the elimination of machining accuracy variation and excellent dimensional stability against thermal displacement made possible by the MULTUS series.

Rapid increase in inquiries for seismic isolation devices and jack-up systems for bridge piers

A notable change after installing the MULTUS B750 has been the rapid increase in inquiries for large ball screws used in seismic isolation systems installed beneath building foundations and in jack-up systems for Shinkansen bridge piers.

In Japan, few companies are capable of machining large components for seismic isolation systems, allowing us to leverage our technological strengths in large-component machining that we developed over many years, along with having the equipment capable of handling such sizes. In particular, demand for seismic isolation systems has been rising for buildings, apartments, and public facilities in response to frequent large earthquakes, and we expect new inquiries will continue to increase.

This eliminates variations in machining accuracy, shortens lead time, and improves delivery scheduling

Impressions after installation

Zero collisions thanks to the Collision Avoidance System

The most critical risk on the machining floor is collision between tools, workpieces, and machine structures. In the past, collisions sometimes occurred even when we believed we had carefully checked movements and interference. This resulted in machine stoppages, repairs, and delivery delays. However, with the standard-equipped Collision Avoidance System, we can run machining simulations in advance, and the axes automatically stop before a collision occurs—even if there is a program input error. This provides exceptional peace of mind and greatly reduces the psychological burden on operators. Even for first-article machining, preparation time has been significantly reduced. As a result, collision incidents with multitasking machines equipped with this function are virtually zero.

Outstanding dimensional stability of the MULTUS—even when starting up machine on a winter morning after the holidays

Our plant is located in Tsuru City, Yamanashi Prefecture, a basin with large temperature differences between morning and night. Winter mornings can be particularly cold. Even during such periods, when we start up the machine early in the morning after a holiday, the dimensional accuracy of the first product and that of a product machined more than 10 hours later show almost no variation, allowing us to perform continuous machining with confidence. Although thermal displacement control in large machines is often said to be difficult, the dimensional stability of the MULTUS B750 is superb even when machining large shafts that are 3,000 to 4,000 mm in length, and corrective machining in subsequent processes is rarely required.

High machine rigidity, Okuma's trademark, can clearly be felt even in multitasking machines

During my time as a sales representative for a major mechanical component manufacturer, I had visited many different factories. I also experienced doing hands-on machining at my father’s plant. Even back then, the rigidity of Okuma machines stood out as exceptional. This remains unchanged with their current multitasking machines. We have machined high-hardness materials such as die steel (HRC60), and the machines cut through them effortlessly, sending chips flying in a way that is truly satisfying to watch. I believe this reflects Okuma’s unwavering commitment as a machine tool manufacturer: only with outstanding rigidity can true machining accuracy be pursued.

Outlook to the future

Automating small workpiece loading and unloading with the mobile collaborative robot OMR20

Simple tasks such as workpiece loading and unloading can be entrusted to a robot, allowing operators to focus on higher value-added work

As our first step toward promoting automation and labor savings, we introduced the mobile collaborative robot OMR20. Although we are still in the trial phase, we currenty have the robot handle the loading and unloading of around 10 to 20 small workpieces. This allows operators to use the freed-up time for more value-added tasks, such as preparing for the next machining process or studying new machining methods, thereby utilizing their time more effectively. What we found particularly convenient is the robot’s mobility. Because it can be freely moved, we can flexibly change the machine the robot is connected to depending on the situation—for example, connect it to Machining Center A in the morning and Machining Center B in the afternoon. Currently, we only have one OMR20, but we are considering to install additional units as we continue to verify its effectiveness.

In our third plant, now under preparation for construction, we aim to further maximize the performance of our machine tools and respond to growing demand for seismic isolation devices, semiconductor manufacturing equipment, and infrastructure- and medical-related applications. (Yoshikazu Shirakawa)

Customer Information

Shirakawa Co., Ltd

(Tsuru City, Yamanashi Prefecture)

In 1964, the father of the current president founded Shirakawa Seiki Seisakusho, a company specializing in lathe machining, in Otsuki City, Yamanashi Prefecture. The business gradually shifted from small mass-produced parts, where competition was intense, to doing precision machining of large components within the high-mix, low-volume production market. The company changed its name to Shirakawa Co., Ltd. in 2002 and relocated to Tsuru City in 2010. With proprietary expertise in precision machining of large shafts, the company displays strong capabilities in fields such as precision machinery, industrial robots, LCD production equipment, automotive, semiconductor manufacturing equipment, and medical devices. In recent years, Shirakawa has strengthened their ability to manufacture large ball screw components for seismic isolation systems used for earthquake countermeasures, an area where demand has been rapidly increasing.