- HOME

- Intelligent Technology

Okuma's Intelligent Technology

Advanced machining infrastructure that revolutionizes the manufacturing environment

This intelligent machining infrastructure supports high accuracy and high productivity, geting the best out of each machine with no thermal deformation, no collisions, no chatter, and automatic adjustment to the best cutting conditions.

Realization of high precision

Manageable Deformation-

Accurately Controlled

Thermo-Friendly Concept

Gauging and compensatiom

of geometric error

5-Axis Auto Tuning System

Optimized Servo Control

SERVO NAVI

Improvement of ease of use

Collision prevention

Collision Avoidance System

Cutting condition search

Machining Navi

Shop floors with Okuma’s Intelligent Technology transform manufacturing.

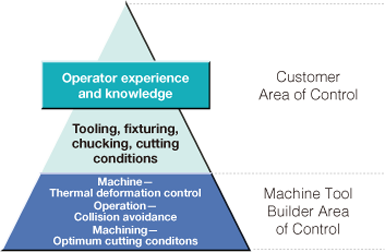

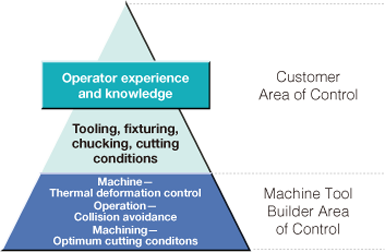

Until now, thermal deformation has been understood as a “machine peculiarity” and the search for cutting conditions and confirmation of collision prevention as “operator skills.” It was thought quickly overcoming these problems was dependent on machining know-how and seasoned skills.

However, tremendous energy was spent before such machining know-how could be displayed—the headache of dealing with thermal deformation of the machine from temperature changes, lowering of cutting conditions to avoid chatter, and expenditure of time to check collision prevention.

Okuma, in the process of analyzing these shop floor issues, understood several of them to be in the technical sphere of machining infrastructure that machine tool manufacturers should provide to customers, and revolved to revolutionize this field.

We combined original machine technology, electronics and electrical technology, and the information technology to integrate them at a high level and achieve on actual machines the “desktop theory” that was thought to be impossible in practice.

The “intelligent technology” born of these efforts greatly increases the level of shop floor machining infrastructure and creates a manufacturing environment in which customers can fully display their essential machining know-how.