THE ROID STORY

Next-Generation Robot System ARMROID

Made possible because of Okuma's leadership as Your Single Source for M-E-I-K (Mechanics - Electronics - IT - Knowledge creation).

Our thoughts on the future of manufacturing . . .

Next-Generation Robot System ARMROID

Made possible because of Okuma's leadership as Your Single Source for M-E-I-K (Mechanics - Electronics - IT - Knowledge creation).

Our thoughts on the future of manufacturing . . .

Technology Division General Manager-

Product Development Department 2

Okuma Corporation

We have always faced issues on the production floor such as labor shortage, and repeatedly searched for ways to improve productivity. Under such circumstances, the ARMROID project was launched with the idea that we could create new value by a fusion of robots and machines. The robot instead can do the work that a person had to do, which is an easy way to automate. Based on this concept, I just single-mindedly investigated what the robot should do. I found out that skilled workers perform their jobs in various ways. I thought to myself, "Oh, I see. They even did things like that!? So let's just make a robot to do that!" That was the beginning of serious development for something like the ARMROID.

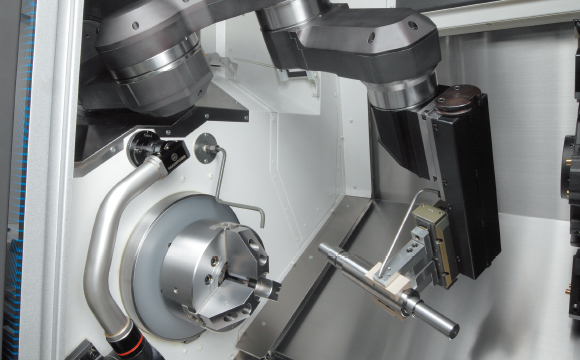

Without a doubt, it's because of our advanced fusion technology, which enabled a smooth integration of machine tool and robotics engineering. First of all, we are putting a robot that can perform various collision-free jobs in the work area while turning a part.

That enables us to provide a machine with built-in robotic automation in the same space as a conventional machine tool.

I think this is a big achievement.

Furthermore, the robot can be operated in the same way as a machine tool. Until now, creating a robot operating program required special programming language skills as well as expertise and knowledge, and it is difficult to find personnel capable of handling both machine tools and robots, which can be a

bottleneck for bringing in robotic systems. However, ARMROID is equipped with an easy-to-use robot operation tool named ROID Navi that only requires interactive inputs of numbers. So it’s possible for both the machine and robot to move easily without any worries. I think this was achieved only because Okuma has the technology that combines what we call M-E-I-K which stands for Mechanics - Electronics - IT - and Knowledge.

For example, suppressing chatter that occurs during machining. This knowledge was learned from the work of a skilled machinist using a manual general purpose lathe. The tool wears out as the machining continues for a lengthy job. Then, the part that had been turned so far begins to vibrate and you can’t get a clean cut surface. When that happens, an experienced machinist can control the vibration by pressing a bevel on the turning workpiece. Now we let the robot suppress chatter. With CNC machine tools, people cannot enter the work area during cutting, but ARMROID, a built-in robot, can work inside the machine.

In addition, the robot, instead of an operator, can work in the machine to remove chips, which is another troublesome but necessary task. ARMROID can also perform mixed blasting of coolant and air to prevent chips from getting entangled with the workpiece. I look forward to hearing from various customers

interested in learning how a robot can perform this kind of work.

We are continuing our R&D to see what else is possible with ARMROID.

Regardless of the size of the factory itself, I think ARMROID is suitable for shops where high varieties are produced in low to medium-volume batches per day. ARMROID will surely solve problems such as the aging and the shortage of workers.

In addition, ARMROID can work in tandem with a sliding workpiece stacker attached to the front of the machine, making it is easy to work share—operator for morning/afternoon shifts—robot for lunch-break/night shifts. I think the working hours for employees can be reduced and the way they work can be changed. We believe the introduction of ARMROID will surely take us to a new future in manufacturing.