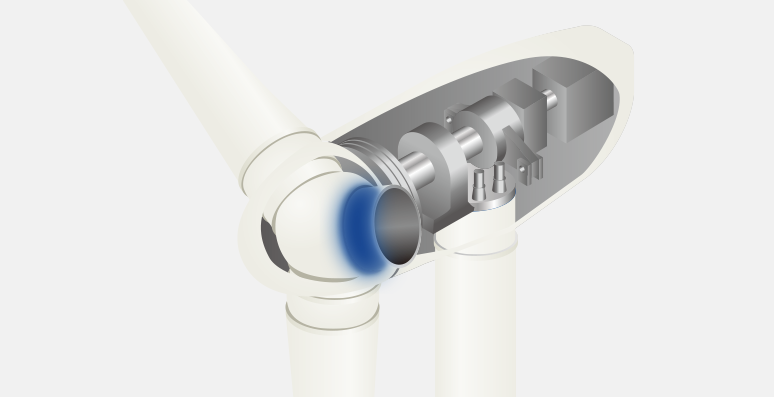

Process integration of turning process of large diameter parts and machining large diameter tapped holes

POINT 01

- High machining capacity that matches those of large lathes and machining centers

-

- Highly efficient machining of large diameter components

- Turning: 6.5 mm2 (S45C)

Milling capacity: 1,003 cm3/min (S45C) - Turning spindle max torque: 6,000 N-m

Milling tool spindle max torque: 505 N-m - machining diameter: ø1,200 mm

Highly efficient machining of large diameter components (referential video featuring alternate components)

POINT 02

- Highly efficient machining of large diameter tapped holes using a 5-axis vertical multitasking machine

-

- Large-diameter tapped holes are efficiently machined using helical machining, which involves moving the end mill in a spiral pattern along the Y-axis.

Helical machining operations