PRODUCTS

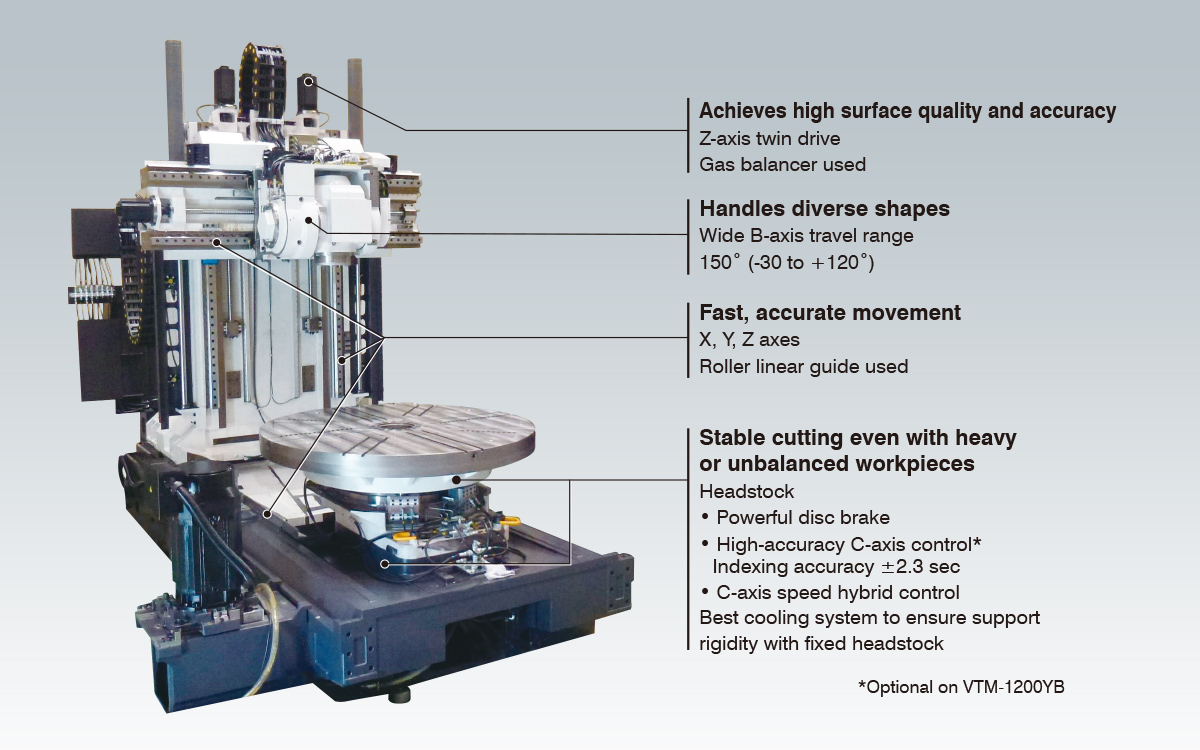

Superior machine structure delivers high performance

- Highly rigid structure that gives stable accuracies

-

- Integrated structure column resists twisting and bending

- Fixed headstock for high rigidity

- Spindle structure also handles unbalanced workpieces

-

- Spindle bearing:

- VTM-1200YB ø260

VTM-2000YB ø200 + thrust bearing ø650

-

- Loading mass:

- VTM-1200YB 3,000 kg (chuck included)

Optional 5,000 kg

VTM-2000YB 10,000 kg (chuck not included)

- High speed operation

-

- Faster axis feeds 32 m/min (X-Y-Z axes)

- Shorter ATC time (C-C) 12.5 sec

- Shorter B axis indexing 2.4 sec/90°

-

High machining capacity even with difficult-to-cut materials

- Turning [VTM-2000YB actual data]

- Heavy-duty cutting: 6.5 mm2

(Workpiece: S45C) -

![Turning [VTM-2000YB actual data]](/english/product/mm2/images/vtm1200yb/p_product03.jpg)

- Milling [VTM-2000YB actual data]

- Face milling Stock removal: 1,000 cm3/min

(Workpiece: S45C, Tool: ø100 mm face mill 10-flute) -

![Milling [VTM-2000YB actual data]](/english/product/mm2/images/vtm1200yb/p_product04.jpg)

* The above are actual examples. Your results may vary due to differences in specifications, tooling and cutting conditions.

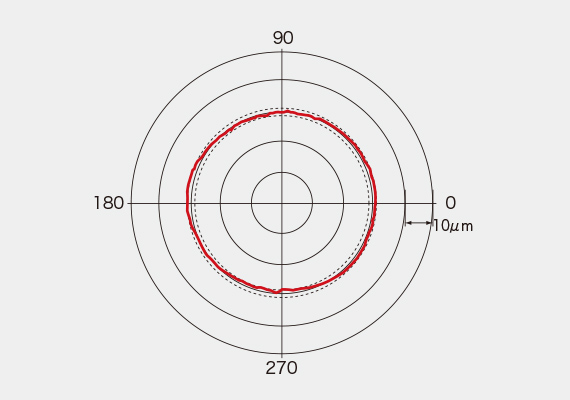

Highly accurate control

- Circular cutting (X-Y planes)

- Roundness:2.1 μm (actual data)

-

- Material: Al

- Machining dia: ø115

- Machining width: 25 mm

- Tool: Carbide end mill ø13 mm (4-flute)

- Cutting: 326 m/min(8,000 min-1)

- Feedrate: 1,000 mm/min(0.03125 mm/flute)

- B-axis control

-

- Standard: 0.001° indexing

- Optional: NC-B axis (simultaneous 5-axis control)

* The above are actual examples. Your results may vary due to differences in specifications, tooling and cutting conditions.

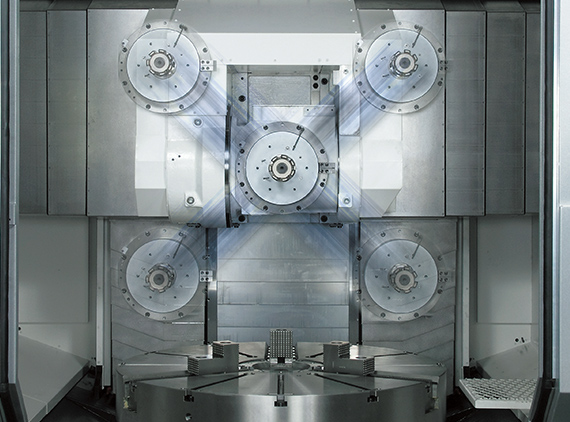

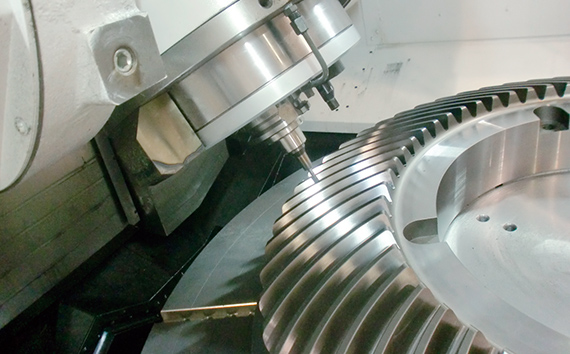

Simultaneous 5-axis machining: B-axis NC control (optional)

- 〈Process-intensive machining of large spiral bevel gears〉

-

Process-intensive machining on one multitasking machine of processes normally done on three different machine types, including expensive special purpose machines. Not only are equipment costs and installation space greatly reduced; lead times are also a significantly shortened.

High-accuracy machining is achieved with simultaneous 5-axis control (B-axis NC) and a highly accurate C axis. -

Single pitch accuracy JIS Class 5

(former JIS grade 1)

Accumulated pitch accuracy JIS Class 2

(former JIS grade 0) -

-

- Main specifications:

- B-axis NC control

High-accuracy C-axis

Super-NURBS (high-speed contouring)

Tooth surface finishing

(HRC 60 after quenching)

Cycle time: 17 hr 42 min -

Highlighted Specs

| Item | Unit | VTM-1200YB | VTM-2000YB |

|---|---|---|---|

| Applicable chuck sizes | in | 36, 40 | - |

| Maximum table size | ømm (øin) | 1,250 (49.21) | 2,000 (78.74) |

| Max machining dia | ømm (øin) | 1,200 (47.24) | 2,000 (78.74) |

| Max work length (height) | mm (in) | 1,080 (42.52) | 1,400 (55.12) |

| Spindle speed | min-1 | 500 | 300 |

| Tool storage | tools | 36 | 36 |

| Motor | kW (hp) | 30/22 (30 min/cont) (40/30) | 30/22 (30 min/cont) (40/30) |

| Machine size (W × D × H) |

mm (in) | 5,512 × 5,471 × 4,273 (217.01 × 215.39 × 168.23) |

5,970 × 6,973 × 4,967 (235.04 × 274.53 × 195.55) |

| CNC | OSP / FANUC | OSP / FANUC |