- HOME

- Technology & Solutions Solutions by industry

- Semiconductor industry

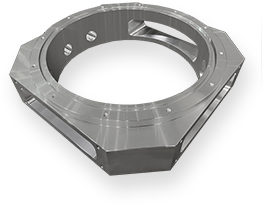

- Polygonal chambers

Polygonal chambers

Vacuum chamber parts of semiconductor manufacturing devices

Material: A5052

Processes from turning to milling can be completed without chuck change or setup change time

POINT 01

- Reducing time and effort of setups with process-intensive machining of turning and milling

-

- Making it possible to conduct turning, milling, machining of slant holes, and multi-sided machining without chuck change

- Reducing accumulated errors of workpiece attachment by decreasing the number of times of setup to shorten the lead time

- Decreasing the design and manufacturing costs by reducing setup parts

Accomplish various machining without chuck change

POINT 02

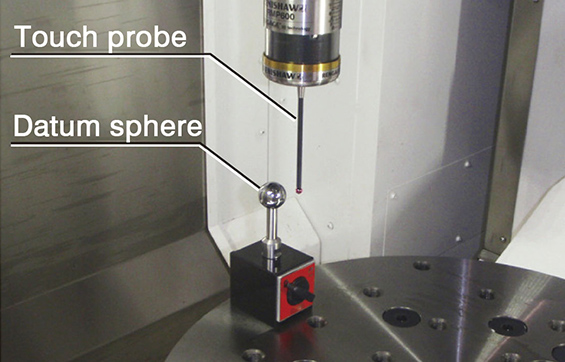

- Maintaining 5-axis machining accuracy for a long time

-

- Correcting geometric errors automatically with 5-Axis Auto Tuning System

- Allowing any worker to easily correct the accuracy of the 5-axis machining center, which was formerly difficult to adjust, reducing boundary errors and hole position errors

POINT 03

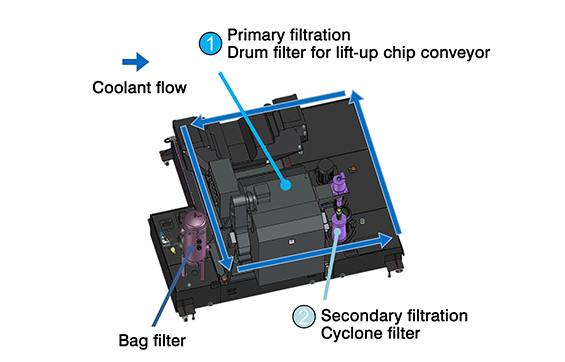

- Achieves long-term stable operation with a sludgeless tank

-

- Aluminum sludge removal rate: 99%

- Reducing drastically the number of times troublesome tank cleanings

- Reducing waste coolant to reduce environmental burdens