Process-intensive machining and automation enable unmanned operation for many hours

POINT 01

- Integrating turning process into a 5-axis machining center

-

- Milling and turning processes are completed with one machine.

- Turning: 3 mm2

- The number of setups and workpiece transportations between processes are minimized to reduce labor and chucking errors.

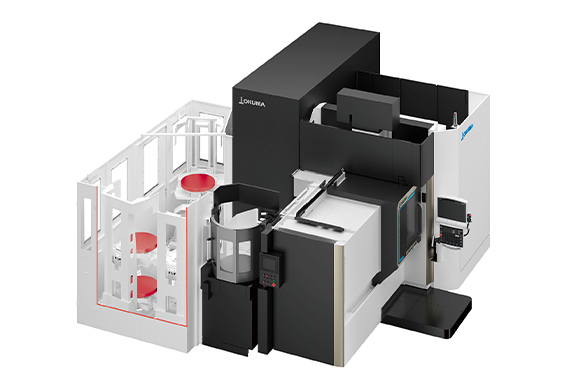

POINT 02

- Labor saving using an automatic pallet changer (APC)

-

- A multi-pallet APC is used to enable unmanned operation for many hours.

- External setup of workpieces improves the operating rate of the machine.

- Access to the inside of the machine is good even for APC specs.

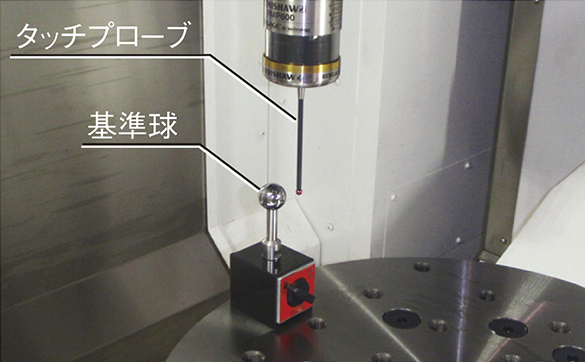

POINT 03

- 5-Axis Auto Tuning System Ⅱ enables highly accurate 5-axis machining to be maintained for a long time

-

- Anyone can quickly and easily measure and correct geometric errors.

- Machines automatically correct up to 11 types of geometric errors, allowing for quick and easy tuning.

- In synergy with the Thermo-Friendly Concept, the accuracy of 5-axis machining is maintained over a long time.