Machining of mass-produced components through a combination of process integration and automation

POINT 01

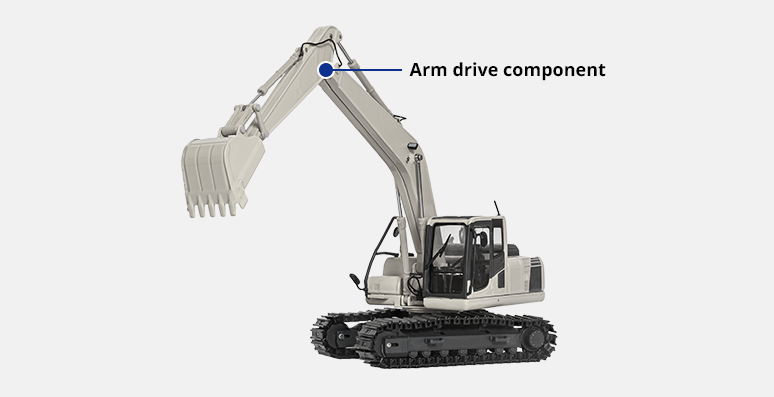

- Process integration for mass-produced components

-

- In addtion to turning, it is possible to machine figure-8-shaped oil grooves and side holes on inner diameters, as well as doing continuous machining of process 1 and 2 by using a sub-spindle.

- Integrating processes for mass production allows for efficient utilization of factory floor space

POINT 02

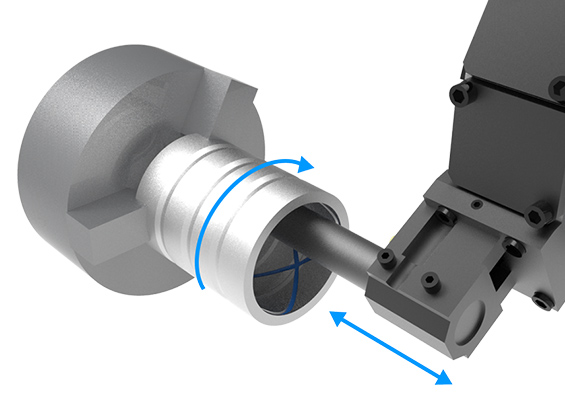

- Easy automation with smarTwinCELL

-

- Collision-free robot motion paths are automatically generated

Even operators without specialized knowledge can operate the robot with confidence - Robot movements can be simulated and verified in advance on an office PC

Significantly reduces setup time for new parts and minimizes machine downtime

- Collision-free robot motion paths are automatically generated

smarTwinCELL (MULTUS B300Ⅱ)