- HOME

- Technology & Solutions Solutions by industry

- Construction machinery industry

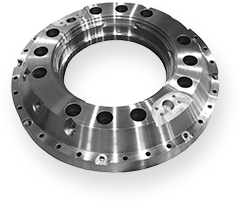

- Large flange component

Construction machinery industry

Construction machinery industry

Large flange component

Drive component |

Wheel component

Material: S45C

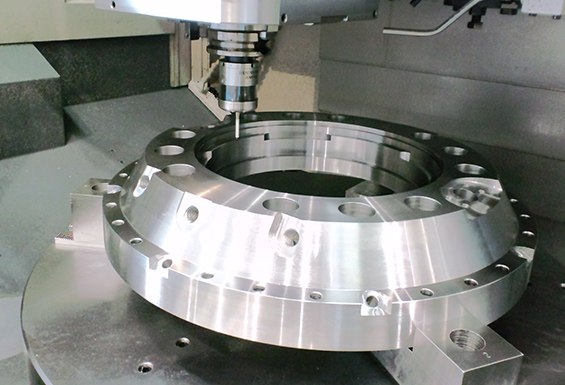

Process-intensive machining of large complex-shaped components on a vertical multitasking machine

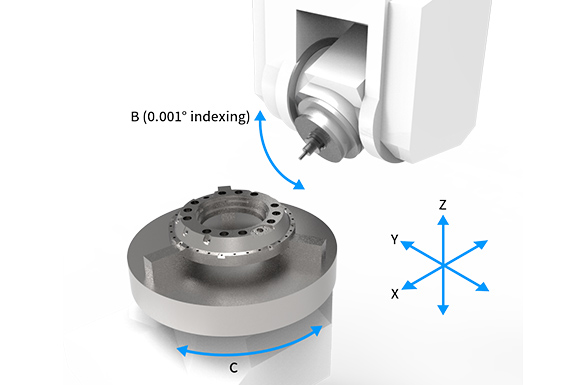

POINT 01

- Possible to machine a multi-sided shape workpiece in a single-chucking operation

-

- Processes such as turning, the drilling of vertical, horizontal, and angled holes, and surface machining using the Y-axis function can all be integrated into one machine.

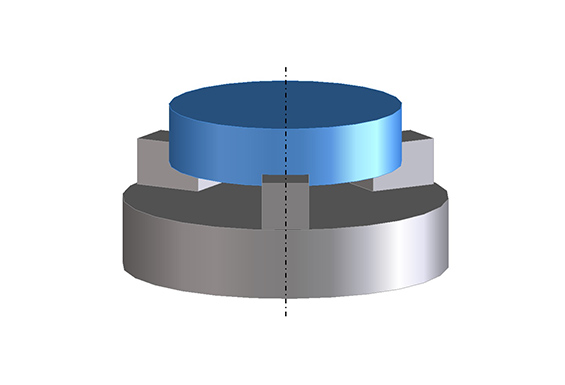

POINT 02

- Stable chucking of thin heavy components

-

- Components are secured firmly under their own weight for stable chucking

- Distortion from clamping force is minimized, enabling high-accuracy machining even for thin components

POINT 03

- High-accuracy machining using in-process gauging

-

- Diameter measurement and compensation feedback are performed using the Y-axis stroke (1,000 mm), which matches the maximum machining diameter (ø1,200 mm)