Integration of highly efficient turning and dovetail grooving

POINT 01

- Stable machining of dovetail grooves using a forming tool

-

- Machining capacity that matches those of large lathes and large machining centers

Dovetail grooves that cause high machining loads can also be machined in a stable manner - Turning: 6.5 mm2 (S45C)

Milling capacity: 1,003cm3/min (S45C) - Turning spindle max torque: 6,000 N-m

Milling tool spindle max torque: 505 N-m - Max machining diameter: ø1,200 mm

- Machining capacity that matches those of large lathes and large machining centers

Machining of a dovetail groove using a forming tool

POINT 02

- Highly efficient machining of end faces using B-axis turning

-

- The X, Z, and B axes are simultaneously controlled during turning to ensure a consistent cutting edge angle.

By maintaining a steady flow of cutting chips, productivity can be increased while ensuring high surface quality.

- The X, Z, and B axes are simultaneously controlled during turning to ensure a consistent cutting edge angle.

B-axis turning of end face

POINT 03

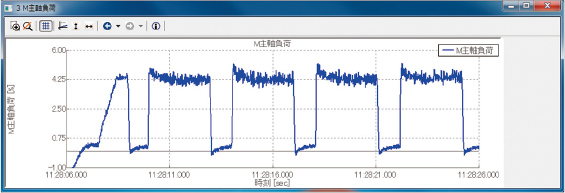

- Traceability is ensured with machine status logger

-

- Load information of spindle and feed axis, external sensor information, and other trace data are linked and recorded with program information, operation information, and other event data.

This allows NC information fo be trackable.

- Load information of spindle and feed axis, external sensor information, and other trace data are linked and recorded with program information, operation information, and other event data.