Highly efficient machining of large, complex-shaped parts

POINT 01

- Highly efficient machining of large parts with powerful 5-axis machining using a high-torque spindle

-

- Spindle torque

- Integral motor/spindle: 1,071 N-m (standard)

- Gear spindle: 1,920 N-m (option)

- Max workpiece dimensions: ø1,500 × 1,175 mm

- Spindle torque

5-axis machining of a propeller hub

POINT 02

- Process-intensive machining of large, complex-shaped parts

-

- Turn-Cut function integrates machining processes for turning large workpieces

- The number of setup changes is minimized, reducing labor and chucking errors between processes

- The Turn-Cut Guide app makes it easy for anyone to calculate time-consuming machining conditions.

By entering the machining diameter and tool information, the required spindle speed and approximate roundness can be calculated.

Turn-Cut

POINT 03

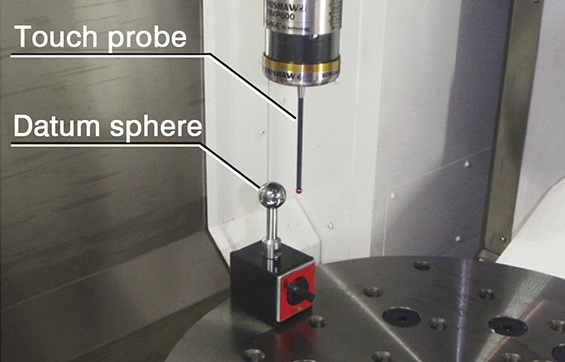

- Our 5-Axis Auto Tuning System maintains highly accurate 5-axis machining over a long period of time

-

- The 5-Axis Auto Tuning System enables anyone to measure and correct geometric errors quickly and easily

- Tuning of up to 11 types of geometric error

The machine automatically performs corrections to enable quick and easy tuning - In synergy with the Thermo-Friendly Concept, accuracy of 5-axis machining is maintained over a long period of time