Integrating machining and measurement processes of long, large-diameter components into a single machine

POINT 01

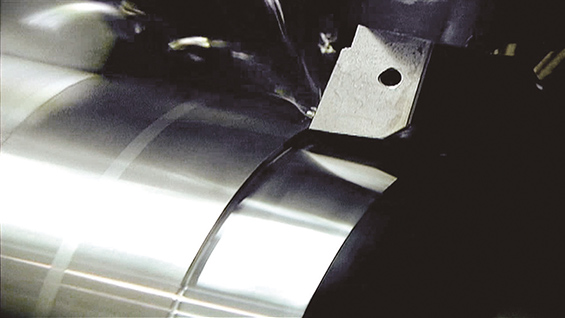

- High machining capacity and wide machining range enable highly efficient machining of long, large-diameter parts

-

- Machining capacity that matches those of large lathes and machining centers

- Turning capacity: 6.5 mm2 (S45C)

- Milling capacity: 1,000 cm3/min (S45C)

- Largest machining range in its class

- Max turning dia: ø1,050mm

- Distance between centers: 3,000 to 6,000 mm

- Y-axis travel: 660 mm

- Machining capacity that matches those of large lathes and machining centers

POINT 02

- Turn-Cut function integrates the turning processes for tilting axes

-

- Turning is possible for tilting axes without the use of a special machine

- The Turn-Cut Guide app makes it easy for anyone to calculate time-consuming machining conditions.

By entering the machining diameter and tool information, the required spindle speed and approximate roundness can be calculated.

Turn-Cut for a tilting axis

POINT 03

- Product management is also integrated based on highly accurate in-process gauging

-

- Geometric accuracy, diameter, and hole position measurement using an NC gauge

-

- Surface roughness measurement using a roughness gauge shortens the lead time

Onboard measurement of geometric accuracy and surface roughness