Highly accurate and highly efficient machining of large, complex-shaped parts

POINT 01

- Complete all machining processes of large, complex-shaped parts with an NC-BC universal head

-

- The NC-BC universal head can machine multiple surfaces, including inclined and curved surfaces, with one chucking. This reduces the setup time.

- Spindle speed can be selected from 6,000 to 20,000 min-1

Frame machining with an NC-BC universal head

POINT 02

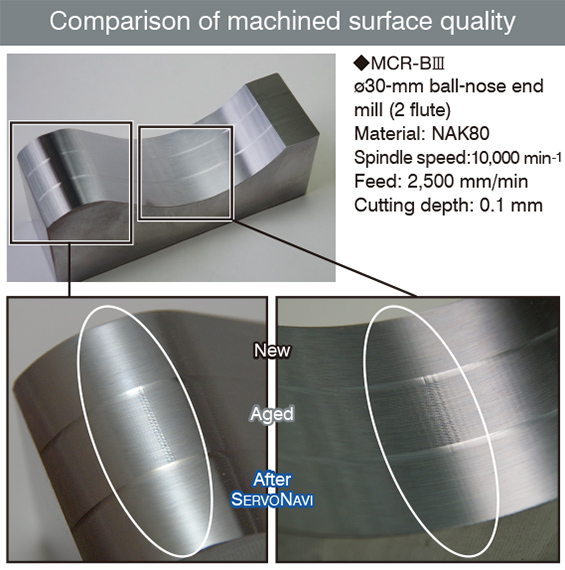

- Automatic optimization of servo control by SERVONAVI improves productivity while maintaining high machining accuracy

-

- Servo parameters are automatically set optimally according to the weight of parts and jigs, shortening the machining time while maintaining machining accuracy

- The machine automatically optimizes servo parameters in accordance with changes over time, such as changes in sliding resistance, to maintain high machining accuracy

POINT 03

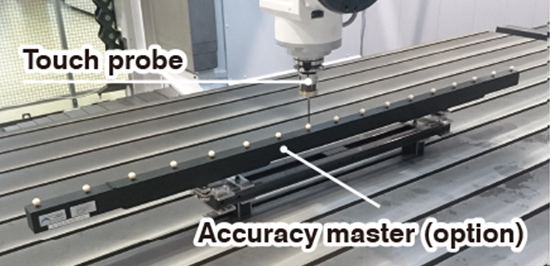

- High accuracy is maintained over the long term

-

- The Thermo-Friendly Concept, Okuma's unique approach of "accepting temperature changes," ensures stable accuracy without the need for special cooling equipment or excessive air conditioning management

-

- The accuracy stability diagnosis function diagnoses changes in machine accuracy to visualize the impact of room temperature changes on machine accuracy and ensure the reliability of measurement and machining

- 3D calibration, which calibrates the spatial accuracy of the machine, is used for regular inspections and calibration of machine accuracy, maintaining high accuracy over the long term