PRODUCTS

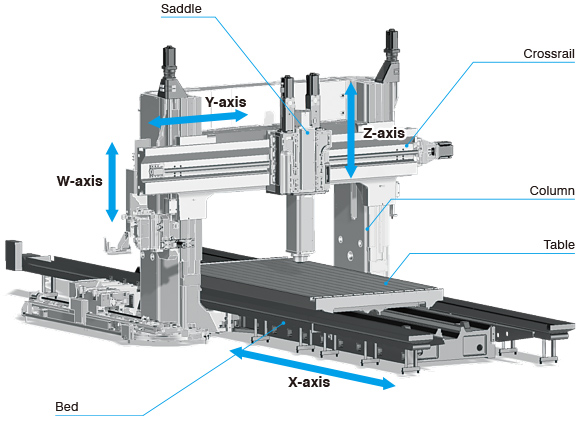

A general-purpose machine for a variety of applications from

high-accuracy machining to heavy-duty cutting

Providing stable machining accuracy even during long runs, from heavy-duty cutting of steel and castings to highly efficient machining of aluminum. One MCR-BV handles a wide range of applications.

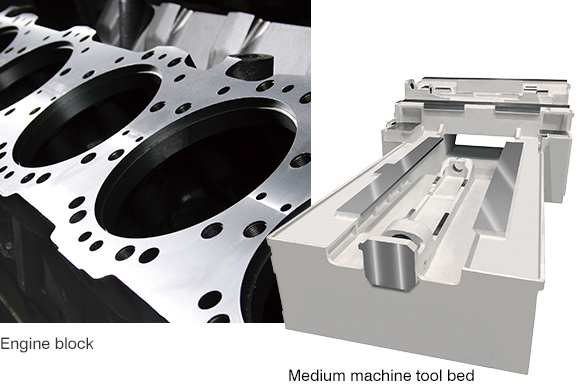

Industries

Being used by machine tool, aircraft, railcar manufacturers and in various other core industries that require higher product accuracies.

Feature

01 High accuracy High accuracy machining specs are standard

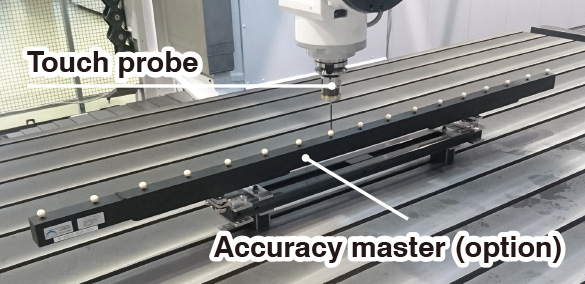

3D Smart Calibration System Calibrates spatial accuracy

Automatic and easy measuring of spatial accuracy with the calibration master and touch probe. Calibrating machine accuracies by any operator is easy.

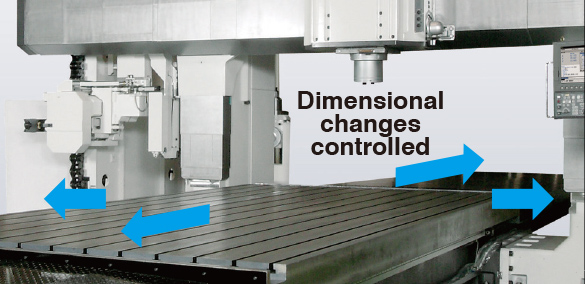

Thermo-Friendly Premium

Thermal deformation control for the large machines

Even for large machines where suppressing thermal displacement is difficult, high dimensional stability is achieved not only when ambient temperatures change, but also for machine start ups or machining restarts.

Accuracy Stability Diagnosis Function

Self-diagnosis of changes in machine accuracy

Self-diagnosis of machine accuracy changes due to uneven factory temperatures and floor thermal deformation.

AbsoScale (X-Y-Z-W axes)

Improved positioning accuracy for each axis

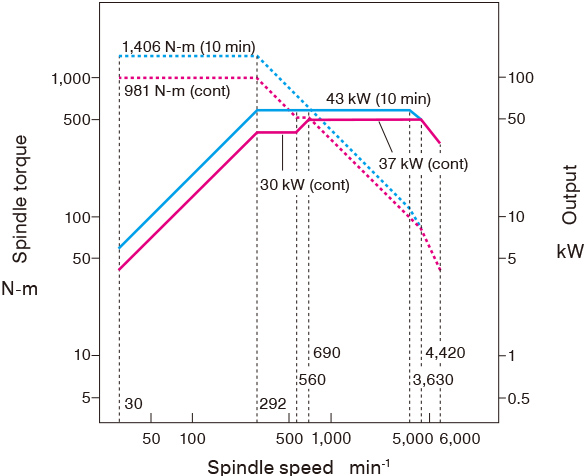

02 High efficiency Spindle with high torque and output integral motor/spindle: standard

Integral motor/spindle with high torque and output

Handling everything from powerful cutting to high-accuracy finishing.

-

- Machining capacity:

- 1,170cm3/min

(Material: S45C; Z-axis protrusion: 600 mm)

-

- Spindle speed:

- 6,000min-1

(integral motor/spindle)

-

- Max output:

- 43/37/30kW (57/50/40 hp)

(10 min/cont (high speed) / cont (low speed))

-

- Max torque:

- 1,406/981N-m

(10 min/cont)

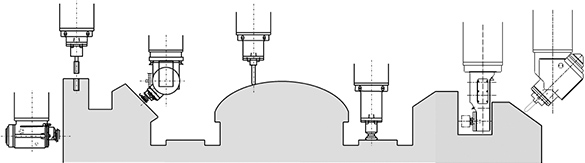

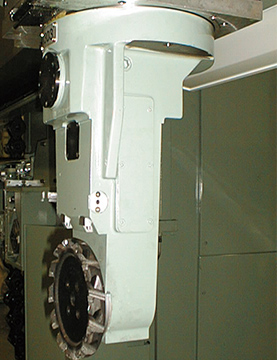

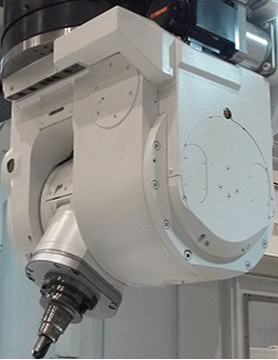

03 Attachment head variations More than 100 types available

Over 100 attachment head types to choose from

A wide variety of attachment heads are available, including the NC-BC universal head with integral motor/spindle (option). Machining parts with complex shapes can be handled by one machine, greatly improving productivity.

Note: The data shown here represent "actual data," which may not be obtained under different environmental, machine specifications, tooling, cutting, and other conditions.

Highlighted Specs

| Item | Unit | MCR-BⅤ |

|---|---|---|

| Effective width between columns | mm (in) | 2,650 to 3,650 (104.33 to 143.70) |

| Table working surface | mm (in) | 2,000 × 4,000 (78.74 × 157.48) to 3,000 × 12,000 (118.11 × 472.44) |

| Spindle speed | min-1 | 6,000 |

| Tool storage | tools | 50 |

| Motor | kW (hp) | 43/37/30 (57/50/40) (10 min /cont (high speed) / cont (low speed) ) |

| Machine size (W × D × H) |

mm (in) | 7,370 × 10,730 × 6,420 to 8,340 × 27,930 × 6,700 (290.16 × 422.44 × 252.76 to 328.35 × 1,099.61 × 263.78) |