Simultaneous 5-axis machining of large parts

POINT 01

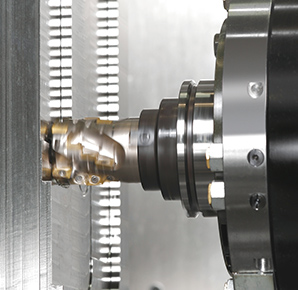

- High-torque spindle enables quick machining of large and complex-shaped components made from difficult-to-cut material

-

- Spindle torque

- Integral motor/spindle: 1,071 N-m (standard)

- Gear spindle: 1,920 N-m (option)

- Max workpiece dimensions: ø1,500 × 1,175 mm

- Spindle torque

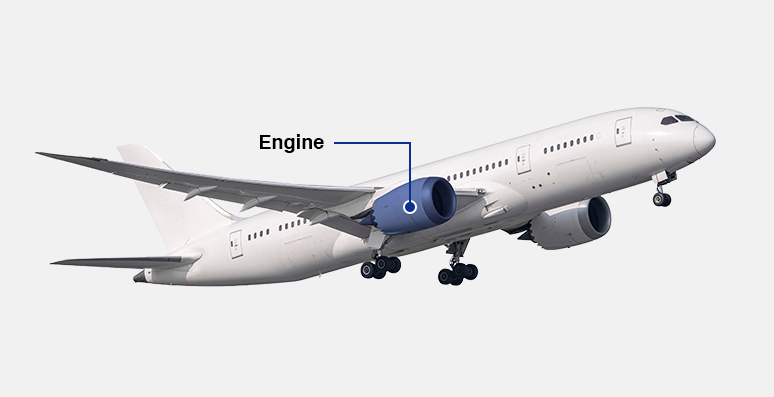

Machining an engine case with a high-torque spindle

POINT 02

- Highly efficient, stable machining of cylindrical parts by turn milling

-

- Highly efficient machining is achieved through turn milling, in which cylindrical parts are machined by rotating the tool and parts at the same time

- Since chips are broken up by intermittent cutting, turn milling has excellent chip handling, and the machining temperature does not rise easily, making it ideal for processing difficult-to-cut materials

Turn milling

POINT 03

- Dynamic Tool Load Control enables stable machining of difficult-to-cut materials and extends tool life

-

- The feed rate is optimized according to the runout of the insert tool's cutting edge

Chipping is suppressed by equalizing the cutting forces - Tool life is improved without compromising machining conditions or using expensive solid cutting tools

- The feed rate is optimized according to the runout of the insert tool's cutting edge