- HOME

- Technology & Solutions Case Studies

- Yoshida Tekkousho Co., Ltd

Case Studies

—Why Okuma was chosen

By insourcing machining processes that were previously outsourced, both high productivity and high accuracy could be achieved.

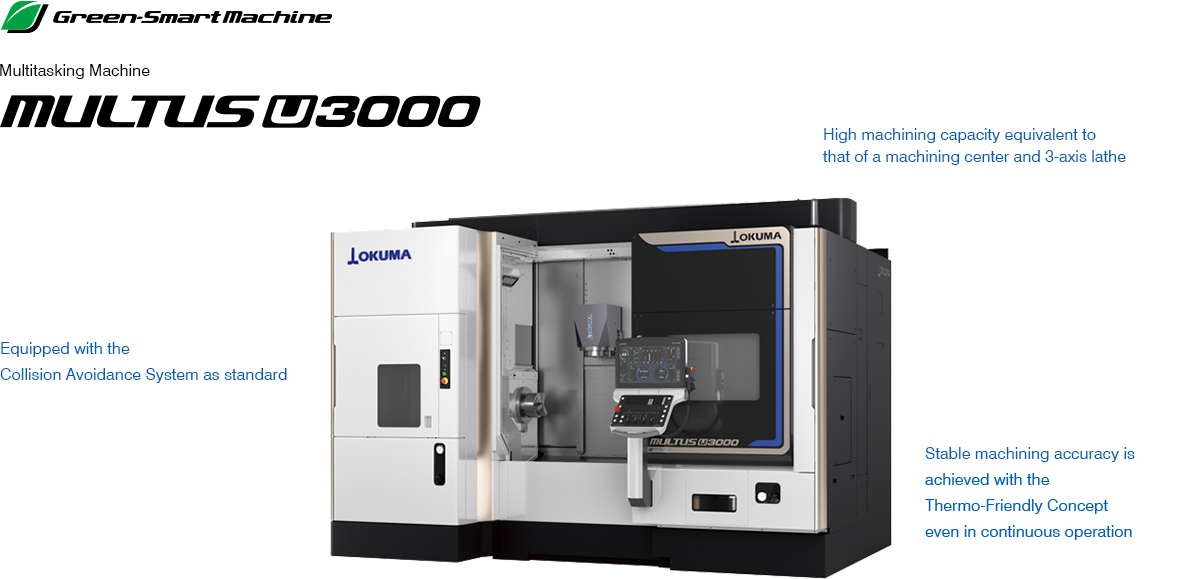

Business expanded with the company's first MULTUS U3000 multitasking machine

Yoshida Tekkousho Co., Ltd

- Industry

- Machining of precision parts

Challenges at the manufacturing site

To recieve orders for high-value-added parts with complex geometries.

The challenge of enhancing high-mix, low-volume production capabilities, while achieving high productivity and labor-saving.

Mainly manufacturing machine tool parts, Yoshida Tekkousho Co., Ltd. has built a history of over 40 years with its turning craftsmanship that has been cultivated since its founding. While planning out how to expand the company's customer base, orders for parts with complex geometries increased, which inevitably caused the outsourcing ratio for machining—the post-process after turning—to increase.

When the president's eldest son agreed to take over the family business, a management review of the company was done. The decision was made to grow the company into one that was capable of delivering high-value-added parts from start to finish by conducting machining processes internally. However, because there was a mountain of challenges—such as how to utilize the limited space within the factory, reducing workload of operators, and how to reduce running costs—there were repeated discussions about what kind of machine should be installed to enhance high-mix, low-volume production capabilities while achieving high productivity and labor-saving.

The Okuma machine selected to solve these challenges

Decisive factor for installation

Based on the requirements of the parts ordered by our customers, the MULTUS U3000 was selected with the expectation that its high machining capabilities and wide workspace area would improve productivity

Since the installation of a new model of machine is a significant capital investment that can affect management, selection of the model was undertaken with care. First, we let ten customers know that we were considering the installation of a 5-axis machining center or a multitasking machine and then asked them what kinds of parts they would order if we installed a new machine. The most common answer we recieved was "flange parts with a diameter of approximately ø400 mm". We also thought that since it would be our first installation of the machine, a familiar lathe-based multitasking machine would be more suitable for us than a 5-axis machining center. We considered multitasking machines of several machine tool manufacturers and ultimately determined that Okuma's MULTUS U3000 multitasking machine was the one that would enable us to perform optimal parts machining from a productivity perspective.

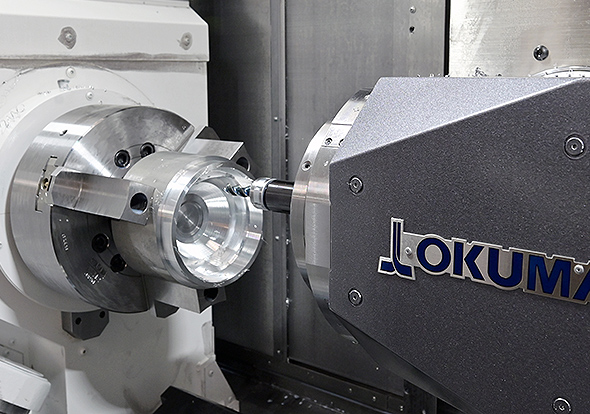

Above all, the MULTUS U3000's turning and milling machining capacities are equivalent to those of a 3-axis vertical machining center and NC lathe. Its high rigidity—which allows it to continue without stopping even when under load—has been proven by the Okuma machines we have used for many years.

It also has many options, which we felt would allow us to pursue various strategies of process-intensive machining and productivity.

Furthermore, my eldest son had a chance to actually operate a multitasking machine at Okuma headquarters and felt a great sense security thanks to the Collision Avoidance System. This encouraged us that this was the machine to install. In order to take on the challenge of machining in new fields, we also selected options such as Hyper-Surface Ⅱ to improve the quality of the machined surfaces of molds, Variable Lead Threading to handle variable pitch threads that are difficult to program, and added a Steady Rest that is essential for precision machining of long shafts. (Takayuki Yoshida)

Yukihiro Yoshida

Effectiveness of machine after installation

Productivity improved by more than 30% after installing the MULTUS U3000 and insourcing machining processes.

Highest monthly sales recorded in the past 40 years.

Previously, we conducted turning in-house and outsourced post-processes that were done on a machining center. However, the MULTUS U3000 enables us to conduct all machining in a single-chucking process. As a result of incorporating machining in addition to turning, we are receiving more orders for high-value-added parts with complex geometries. Since we are able to deliver this kind of machining without outsourcing, it has a profound effect when we receive orders for large quantities. For example, when we received an order for 150 units of the same part in a particular month, once we made an NC program for it, all we had to do after that was to set the workpieces onto the machine. The end result was our monthly sales reaching a record high. It reduces the labor and time required for workpiece transportation, minimizes the workload of workers, but also lessens variations in accuracy. This has allowed us to increase productivity by more than 30%.

Orders for difficult-to-machine components from new customers have also increased.

We receive many inquiries from new customers about new projects in which we are asked if the MULTUS U3000 can handle certain kinds of machining. Compared to before, the types of parts we can machine has increased by 20 to 25. An example of this is a prototype semiconductor-related components that required to cut stainless steel material to a thickness of 3 mm. Although it is not easy to machine such a part, accomplishing this could lead to a mass production order. We are focused on increasing our operation rate even further by fully utilizing the 40 ATC tools on the MULTUS U3000.

Impressions after installation

Stable machining accuracy can be ensured even during continuous operation, eliminating the need for corrective work.

Since the machines in the factory are extremely close to each other, they are significantly affected by heat. However, the MULTUS U3000 can stably maintain high accuracy even during long periods of continuous machining. Thanks to the machine's rigidity and thermal deformation control with the Thermo-Friendly Concept, variations in dimension accuracy do not occur even during long periods of machining. These were concerns before installation, but we ended up worrying for nothing. At full operation in the middle of summer, the temperature in the factory rises so high that our air conditioners do not work. But we expect that the machine will continue to have exceptional dimension stability. (Yukihiro Yoshida)

The Collision Avoidance System eliminates the risks of collisions and provides an exceptional sense of security.

There have been times when in-machine collisions have occurred during machining, so we are grateful to have the Collision Avoidance System as a standard feature that detects interferences and collisions. The Collision Avoidance System automatically stops the machine not only during programmed automatic operation, but also during manual operation. We feel it is an essential function for multitasking machines that have complicated machine operations, because it eliminates the risk of collisions and can greatly reduces time required for setup and the cycle time required for a part that is being produced for the first time.

Outlook to the future

We are also working on doing complicated free-form surfacing using CAD/CAM and would like to be thought of as an indispensable company to our customers.

We believe it will not be long before we can maximize the potential of the MULTUS U3000 by fully utilizing its optional functions, such as Hyper-Surface Ⅱ, Variable Lead Threading, and Steady Rest.

At present, we are aiming to work on complicated free-form surfacing with CAD/CAM. Ultimately, our dream is to become a company our customers value as the "indispensable Yoshida Tekkousho" in terms of quality, cost, and delivery period.

We also envision that we will sell food mixer parts machined with the MULTUS U3000 to Southeast Asia as Made-in-Japan products.

We feel that being able to install such an excellent multitasking machine has enabled us to envision such a thing.

Customer Information

Yoshida Tekkousho Co., Ltd

(Yatomi City, Aichi Prefecture)

In 1981, the founder and former president of the company started Yoshida Tekkousho to process machine tool parts and resin molds. The company started by manufacturing parts with turning and gradually increased its equipment machines to include machines such as CNC lathes, expanding its business to machine parts for heavy industry manufacturers. In 2021, it was incorporated and became Yoshida Tekkousho Co., Ltd. When the eldest son of the current president agreed to take over management of the business, a new decision was made. Processes that required machining had been outsourced until then, but the company decided it was time to do these processes in-house. In December 2024, the company installed its first multitasking machine, the MULTUS U3000, to create new business opportunities and expand sales.