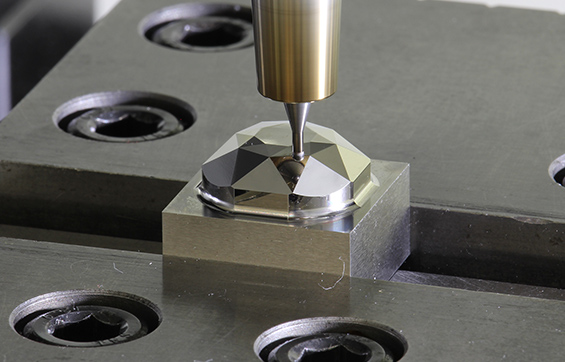

Shower plates

Plates with multiple small-diameter holes for etching devices, etc.

Material: Single crystal silicon

Accurate hole drilling in difficult-to-cut materials

POINT 01

- A high-accuracy main spindle with stable drilling of many multiple small-diameter holes in difficult-to-cut materials

-

- Spindle speed 20,000min-1 (standard)

30,000min-1 (option) - Achieves high-accuracy machining with spindle shaft cooling which minimizes the thermal deformation of the tool edge, and with Thermo Active Stabilizer-Spindle which controls thermal deformation of main spindle correctly

- Spindle speed 20,000min-1 (standard)

(sample workpiece)

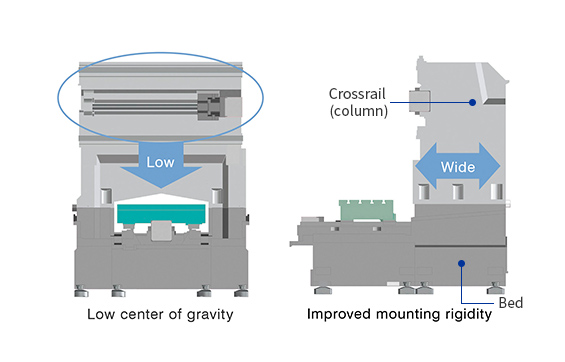

POINT 02

- Making precision machining possible with a machine construction that restrains vibration

-

- Restraining vibration by improving construction of the low center of gravity and the rigidity of the attaching portions of the crossrail (column) and bed Preventing defects of the tool and workpieces when difficult-to-cut materials are machined