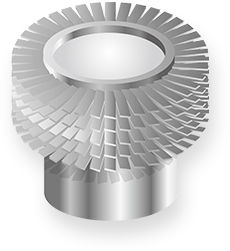

High-efficiency machining with a 5-axis machining center

POINT 01

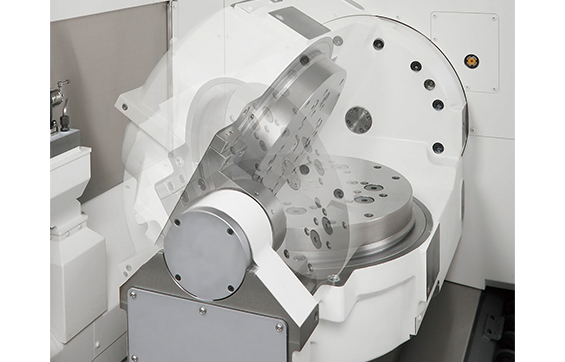

- High-efficiency 5-axis machining

-

- Minimizing tool length and maximizing tool diameter, achieved by optimizing the approach by tilting the workpiece. Shortening the cutting time by improving machining conditions for roughing

- Shortening the cutting time with the formation of a finishing tool path that minimizes the burr removal process

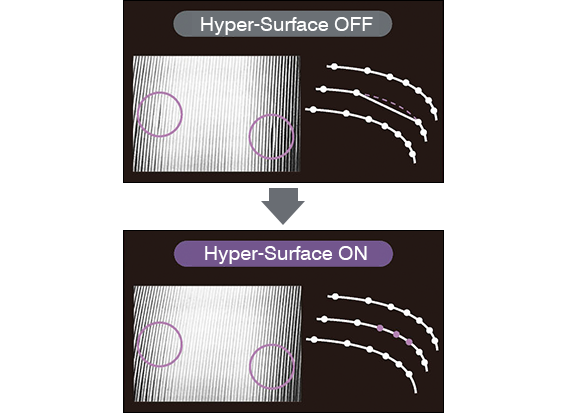

POINT 02

- Automatic correction of the machining program with Hyper-Surface

-

- Analyzing and adjusting the part program in the numerical controller

- Conducting optimal control in each process of roughing and finishing to improve the machining surface quality