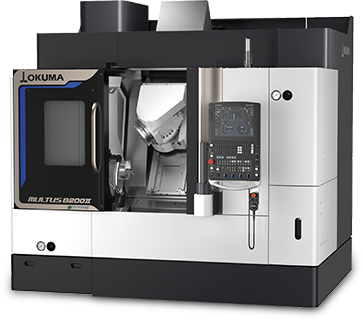

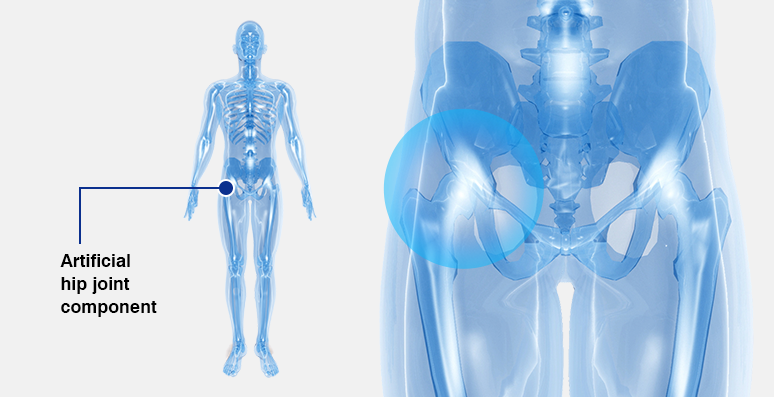

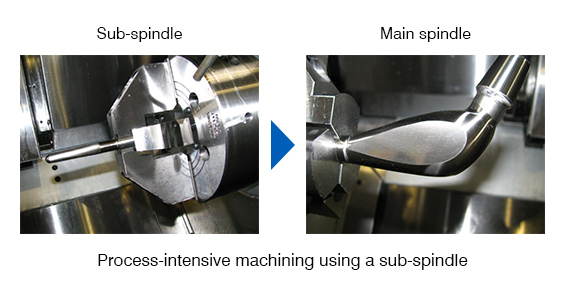

Achieving both high productivity and high-quality machining through process-intensive machining

POINT 01

- The number of setups and workpiece transportations between processes are reduced through process-intensive machining

-

- A sub-spindle is used to complete processes 1 and 2 on one machine.

- The number of setups and workpiece transportations between processes are minimized to reduce labor and chucking errors.

POINT 02

- Achieving high accuracy and high-quality machining

-

- The high-accuracy C axis enables highly accurate indexing for both the main and sub spindles.

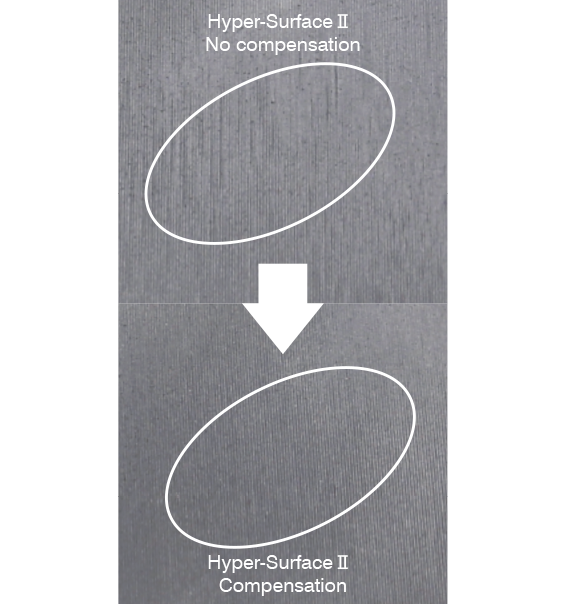

- High-quality machining is achieved through high-speed contouring with Hyper-Surface II.

There is no need to modify CAM machining data.

Ridgelines and uneven surface edges are reduced to improve the machined quality and shorten hand-polishing time. - Automatically compensates for fluctuations in the machining data and positioning errors at edges and between adjacent cutter paths, while maintaining the required shape accuracy

- Vibration is suppressed without slowing down at corners, shortening the machining time and improving surface quality

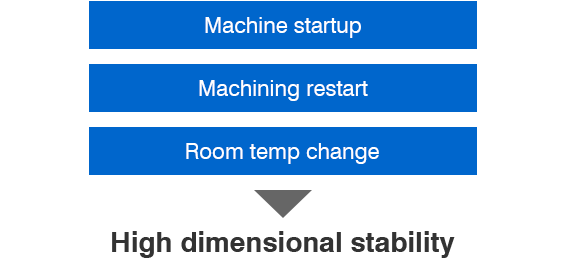

POINT 03

- The Thermo-Friendly Concept enables outstanding dimensional accuracy

-

- High accuracy is achieved even on a multitasking machine that has complex axis configurations.

- Thermal deformation over time less than 10 μm (actual data)