- HOME

- Solutions & Technology

- Support for people and the environment

- Sludgeless Tank

- Production floor issues

- Sludge accumulates in the coolant tank during machining

-

- · Sludge accumulation can cause problems to pumps and cutting tools, and can even cause machine failures

- · Machine downtime caused by tank cleaning leads to loss in productivity

- · Removing sludge and cleaning out tank are burdens on operators

- User benefits

- Coolant performance is maintained over long durations, allowing long and stable operation of machine

-

- · Sludge removal rate of 99%*

- · No coolant replacement for 3 years

- · No tank cleaning for 3 years

Note: All figures are based on results achieved by Okuma

* When the workpiece material is a casting or aluminum

Achieve long and stable operation by removing sludge efficiently

For stable operation of machines, it is essential to remove impurities (sludge) from the coolant.

Tank cleaning is troublesome, generates a bad odor, and causes machine operation to stop for a long time. Okuma's Sludgeless Tank resolves such problems. Efficient sludge removal eliminates the burden on operators, losses caused by sludge, and greatly reduces the frequency of troublesome tank cleaning. It achieves long and stable operation.

Note: All figures are based on results achieved by Okuma

* When the workpiece material is a casting or aluminum

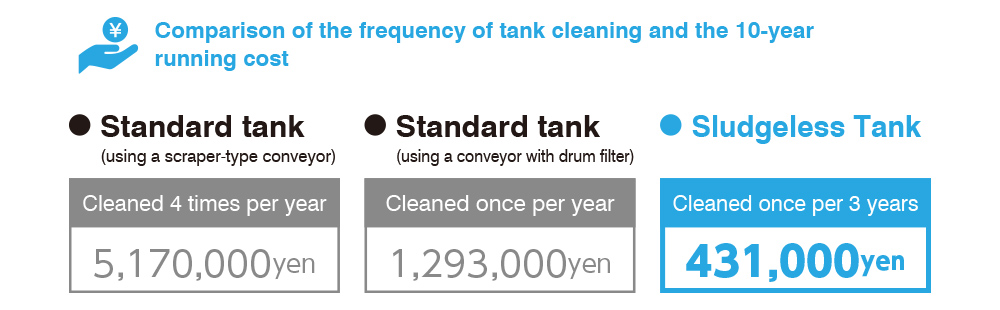

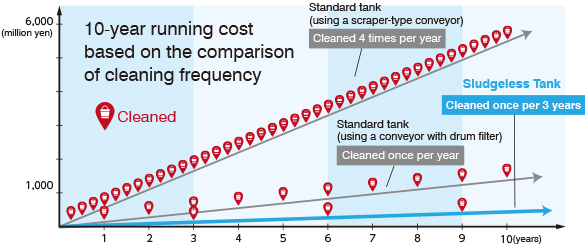

Comparison of the frequency of tank cleaning and the 10-year running cost

Running costs are significantly reduced with a Sludgeless Tank

Note: The running cost varies depending on the machine and specifications.

(based on in-house calculation)

| Annual power consumption |

Reduced by 6,000 kWh |

|---|---|

| Annual electricity costs |

Reduced by 198,000 yen |

Note: All figures are based on in-house calculations.

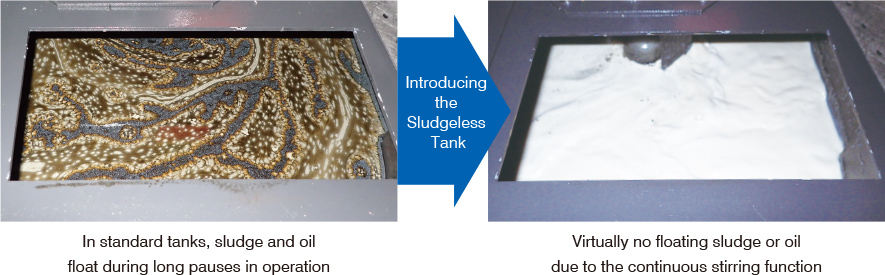

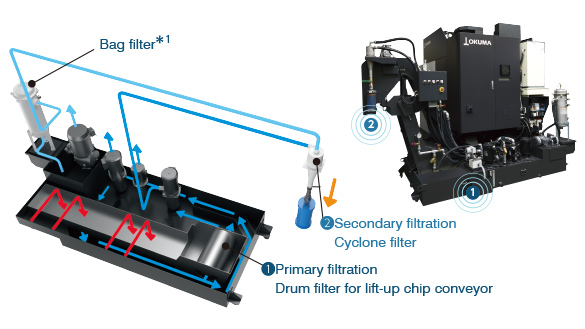

Suppresses deterioration of coolant by removing impurities (sludge) efficiently

By maintaining the coolant flow rate in the tank at a constant speed, the impurities (sludge) contained in the coolant are efficiently removed without sedimentation. Two types of filtration equipment (drum, cyclone) reliably remove sludge. Also, sludge can be automatically collected if conveyor-mounted magnet separator (option) is selected.

Basic structure of the Sludgeless Tank

*1 The bag filter is only available for thru-spindle coolant specification.

Sludgeless Tank Structural Drawing

Note: The machine images and tank structure are those of MB-46VⅡ.

The tank structure varies according to the type of machine.

Note: It is necessary to select chip conveyor with drum filter if the Sludgeless Tank option is chosen.

*1 The bag filter is only available for thru-spindle coolant specification.