PRODUCTSNEW PRODUCTS

Ample machining area for large parts and machine structure that makes setup easy

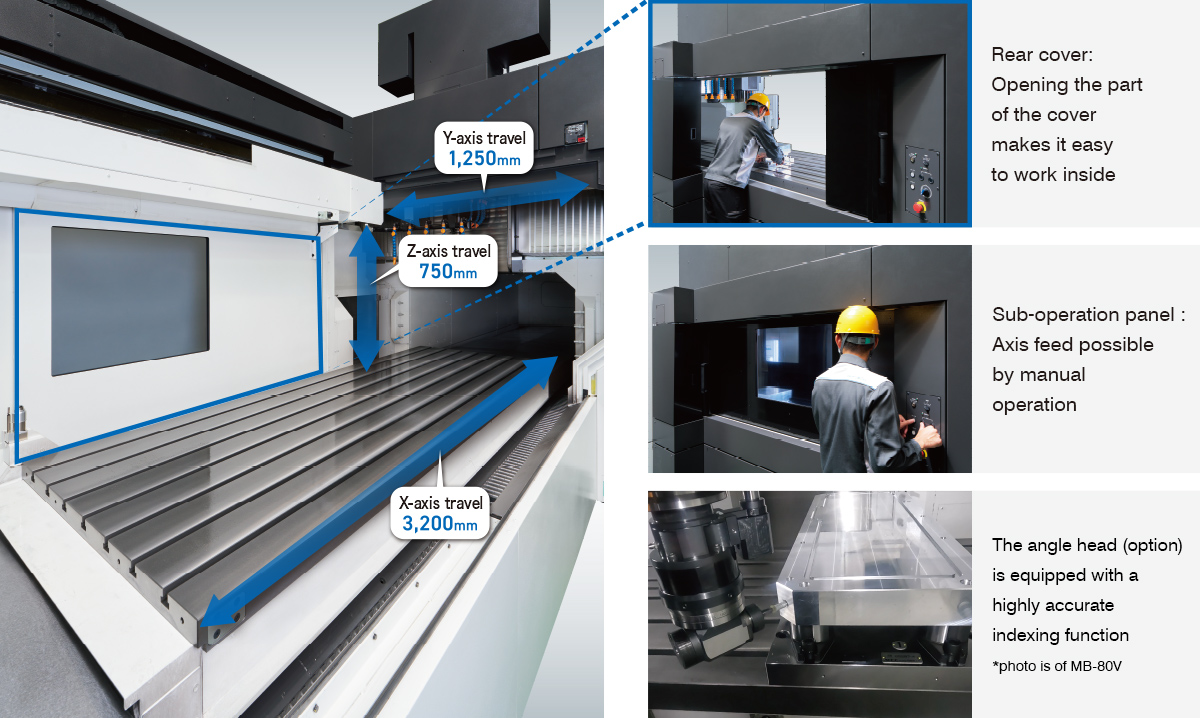

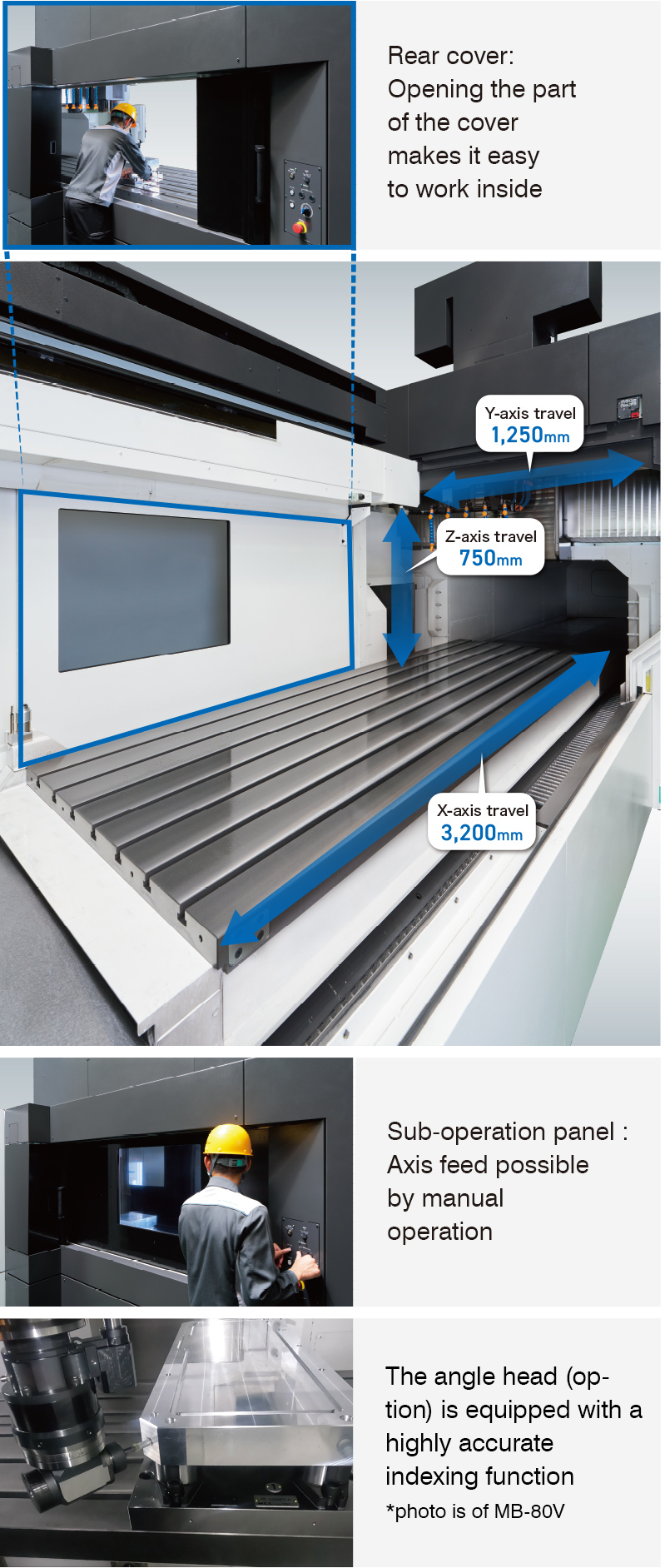

The MB-100V is a powerful, high-precision vertical machining center built with a double-column structure and is able to machine large workpieces with ease. Also, its space-saving design contributes to saving floor space in the factory. The machine construction takes into consideration setup work for large parts, and it is equipped with a large stroke and solutions for multi-sided machining, minimizing the operator’s workload.

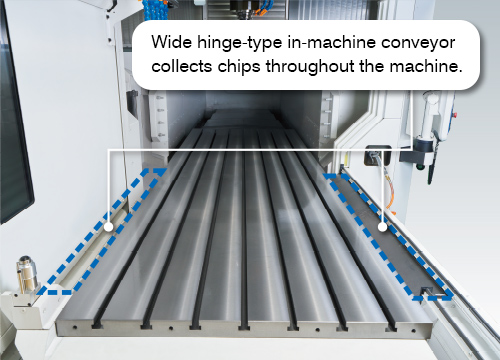

Smooth chip discharge ensures stable operation for long periods of time

The MB-100V smoothly discharges the large amount of chips that are generated, thoroughly eliminating chip troubles that can cause machining to stop.

Vertical surface cover construction that prevents chips from accumulating and wide hinge-type in-machine conveyors enables large amounts of chips to be discharged smoothly.

By installing the ATC arm and cam box outside the machining chamber and cleaning area near the cover, risk of breakdowns are reduced.

Cleaning by the shower installed under the crossrail (option) sweeps away chips from workpieces and the table.

*photo is of MB-80V

A wide range of spindle lineups suitable for machining general parts, dies/molds, and aluminum materials

Spindle Lineup

| Complete machining from highly efficient machining of general parts to rough and finish machining of dies/molds -High power spindle No. 50 roller bearing specifications- |

Spindle speed

12,000min-1

Max output

33/26 kW

(10 min/cont)

Max torque

302/148 N・m

(10%ED /cont)

| Material : S45C actual data Cutting Capacity | 704 cm3/min | (End milling) |

| Tool | Spindle speed min-1 |

Cutting m/min |

Feed rate mm/min |

Cut width mm |

Chips mm |

| ø20 roughing end mill 7 flutes (carbide) | 4,000 | 251 | 9,520 | 3.7 | 20 |

| For a wide range of machining, from steel materials to aluminum materials -Wide-area spindle No. 40 (option)- |

Spindle speed

15,000 min-1

Max output

26/18.5 kW

(10 min/cont)

Max torque

199/146 N・m

(5 min/cont)

| For high speed machining, mainly of aluminum materials -High-speed spindle No. 40 (option)- |

Spindle speed

20,000 min-1

Max output

30/22 kW

(10 min/cont)

Max torque

57/42 N・m

(10 min/cont)

The innovation that accepts temperature changes

Thermo-Friendly Concept

The machining accuracy of workpiece changes significantly due to the ambient temperatures around the machine, heat generated by the machine, and heat generated in machining.

The Thermo-Friendly Concept is a unique concept to “accepting” such temperature changes so that high accuracy can be achieved in normal factory environments with no special measures taken by the user.

Highlighted Specs

| Item | Unit | MB-100V |

| Table size | mm (in) | 3,000 × 1,000 (118.11 × 39.37) |

| Spindle speed | min-1 | 15,000 / 12,000 |

| Magazine capacity | tools | 32 |

| Spindle motor | kW (hp) | 26/18.5 (35/25) (10 min/cont), 33/26 (44/35) (10 min/cont) |

| Machine size (W×D×H) | mm (in) | 8,995 × 3,095 × 3,500 (354.13 × 121.85 × 137.80) |