PRODUCTS

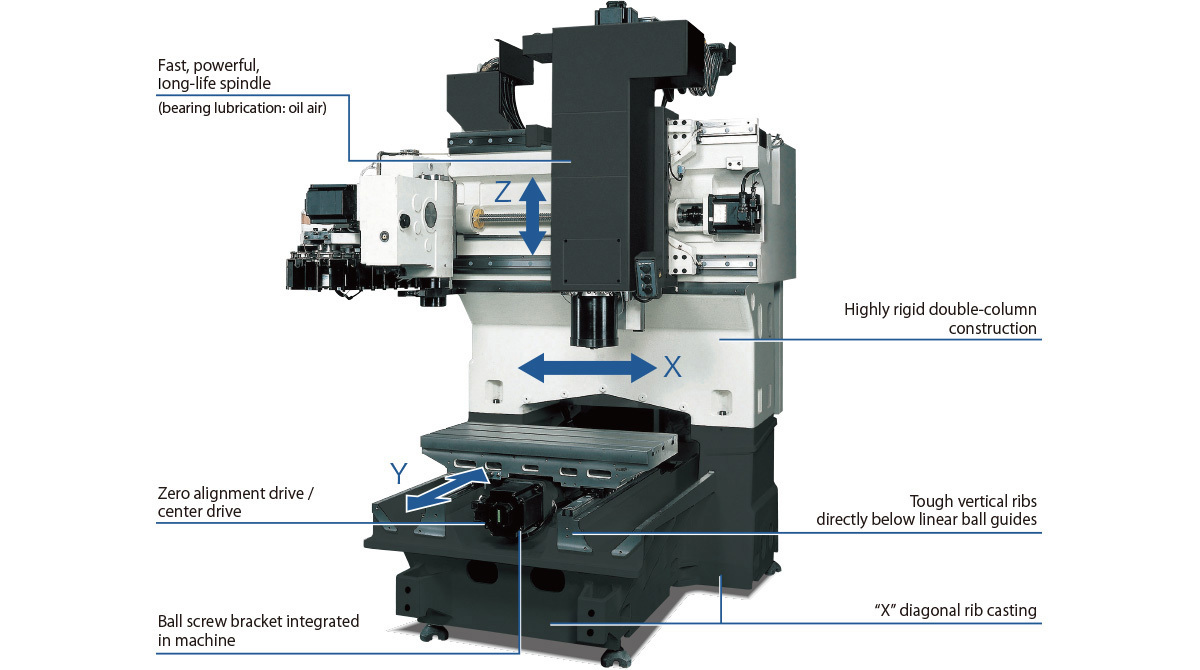

- Highly rigid construction for productivity

that exceeds expectations -

- ・Rugged machine structure developed using 3D-CAD and FEM analysis

- ・Same rugged column structure as used in our proven column machining centers

- ・Bearing bracket of feeding axis integrated into the machine

-

- Powerful spindles

provide heavy-duty cutting with ease -

- Cutting capacities

- 504cm3/min(face milling)

672cm3/min(end milling)

| Tool | Spindle min-1 |

Cutting m/ min |

Feedrate mm /min |

Width mm |

Depth mm |

Chips cm3 /min |

|---|---|---|---|---|---|---|

| ø80 face mill 8 blades (cermet) | 895 | 225 | 2,600 | 56 | 2.5 | 364 |

| ø20 roughing end mill, 7 flutes (carbide) |

3,660 | 230 | 4,300 | 4 | 20 | 344 |

| ø50 insert drill | 1,000 | 157 | 150 | - | - | - |

| Tap M30P3.5 | 318 | 30 | 1,113 | - | - | 60% (Spindle load) |

(Workpiece material: S45C)

| Tool | Spindle min-1 |

Cutting m/min |

Feedrate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

|---|---|---|---|---|---|---|

| ø80 face mill 8 blades (cermet) | 895 | 225 | 3,000 | 56 | 3 | 504 |

| ø20 roughing end mill, 7 flutes (carbide) |

4,000 | 251 | 4,800 | 7 | 20 | 672 |

| ø63 insert drill | 720 | 142 | 108 | - | - | - |

| Tap M30P3.5 | 318 | 30 | 1,113 | - | - | 66% (Spindle load) |

(Workpiece material: S45C)

| Tool | Spindle min-1 |

Cutting m/min |

Feedrate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

|---|---|---|---|---|---|---|

| ø80 face mill 8 blades (cermet) | 895 | 225 | 3,000 | 56 | 3 | 504 |

| ø20 roughing end mill, 7 flutes (carbide) |

4,000 | 251 | 2,800 | 12 | 20 | 672 |

| ø63 insert drill | 909 | 180 | 137 | - | - | - |

| Tap M36P4 | 106 | 12 | 424 | - | - | - |

(Workpiece material: S45C)

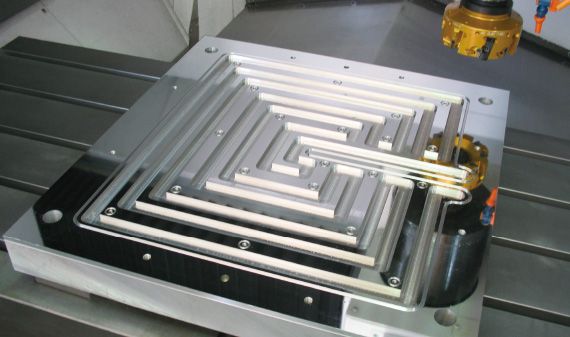

- Parts machined with higher quality

- High-accuracy machining

-

-

- ■Flatness 3μm (actual data)

-

- ・Machine: MB-66VA

- ・Machined part: Plate (LCD)

- ・Material: A5052

- ・Size: 560 × 600 × 60 mm

- ・Cycle time: 50 min

-

-

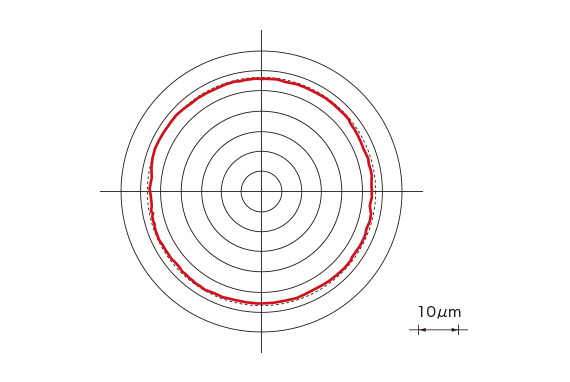

- ■Roundness 1.65μm (actual data)

-

- ・Machine: MB-56VA

- ・Machining dia: ø150 mm

- ・Material: Al

- ・Spindle speed: 8,000 min-1

- ・Feedrate: 2,000mm/min

-

-

- Positioning accuracy

- MB-46VA with AbsoScale; actual data (measurement method based on ISO 230-2)

-

-

- ■The exactness of bi-directional positioning

-

- ・X-axis (travel 560 mm)1.7μm

- ・Y-axis (travel 460 mm)2.4μm

- ・Z-axis (travel 460 mm)2.2μm

-

- ■Bi-directional repeatability

-

- ・X-axis (travel 560 mm)1.0μm

- ・Y-axis (travel 460 mm)1.3μm

- ・Z-axis (travel 460 mm)1.0μm

※The “actual data” referred to above represent examples of data obtained by using ISO 230-2 test methods done at Okuma factories, and they are not guaranteed values.

-

- Thermo-Friendly Concept

- The “Thermo-friendly” concept enables remarkable machining accuracy through original structural design and thermal deformation control technology. If frees you from troublesome dimensional compensation and warm-up. Exhibits excellent dimensional stability even during consecutive operation over long periods and environmental temperature change in the plant.

Highlighted Specs

| Item | Unit | MB-46VA/B | MB-56VA/B | MB-66VA/B |

|---|---|---|---|---|

| Table size | mm (in) | 760 × 460 (29.92×18.11) | 1,300 × 560 (51.18 × 22.05) | 1,530 × 660 (60.24 × 25.98) |

| Spindle speed | min-1 | 8,000 / 6,000 | 8,000/6,000 | 8,000/6,000 |

| Tool storage | tools | 20 | 20 | 20 |

| Motor | kW (hp) | 11/7.5 (10 min/cont) (15/10) | 11/7.5 (10 min/cont) (15/10) | 11/7.5 (10 min/cont) (15/10) |

| Machine size (W × D × H) |

mm (in) | 1,976 × 2,810 × 2,746 (77.80 × 110.63 × 108.11) 2,026 × 2,810 × 2,746 (79.76 × 110.63 × 108.11) |

2,546 × 3,123 × 2,746 (100.24 × 122.95 × 108.11) |

3,035 × 3,325 × 3,295 (119.49 × 130.91 × 129.72) |