PRODUCTSNEW PRODUCTS

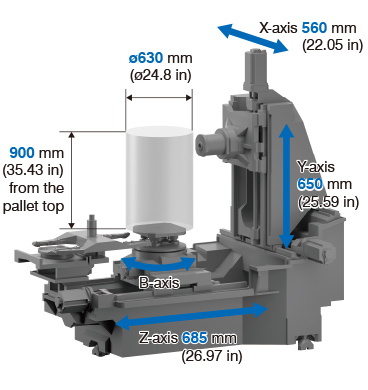

A compact machine with one of the largest machining areas in its class

This machining center has a large machining area despite its efficient use of floor space

Floor space

2,300 × 5,065 mm (90.55 × 199.41 in) (11.6 m2 (124.86 ft2))

Machining area

X-axis travel:560 mm

Y-axis travel:650mm (longer than previous machine)

Z-axis travel:685mm (longer than previous machine)

Max workpiece size

ø630 × 900mm (ø24.8 × 35.43 in)(more than previous machine)

Note: Standard 2-pallet APC specications

Max tool length

450mm (longer than previous machine)

Agile machine operation

Reduced positioning time

- Rapid traverse X-Y-Z axes: 60 m/min (2,362 ipm)

- Rapid traverse acceleration (max)

X-Y axis:1.0G

Z-axis:1.1G*

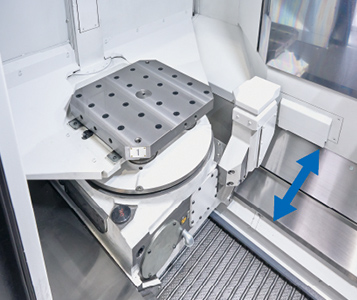

Reduced table indexing time

- 90° indexing:0.8 seconds*

- 180° indexing:0.98 seconds*

* At low inertia

Heavy-duty cutting possible throughout entire machining area

The highly rigid B-axis bearings enable heavy-duty cutting of steel even on the upper Y-axis.

Maximized operation time through chip control

Offers both improved chip discharge functionality and eco-friendly operation

The angle of the internal cover has been increased, and it has been designed with a flat cover inside the machining chamber to greatly improve chip discharge.

A full center trough mechanism prevents chip accumulation by discharging chips from the entire machining area. Pinpoint cleaning of locations where chips tend to accumulate reduces the amount of coolant used and prevents the accumulation of chips while also being environmentally friendly. Easier chip discharge reduces the frequency of internal cleanings that are required, reducing the workload of operators.

“Sludgeless Tank” enhances stable operations (recommended option)

The number of troublesome coolant tank cleaning operations is signicantly reduced, improving productivity.

Furthermore, environmental impact due to coolant disposal is also reduced.

| Sludge removal rate |

99% Notes: After secondary ltration (cyclone lter) permeation |

|---|---|

| No coolant tank cleaning required for 3 years (Okuma equipment actual data) |

|

| No coolant replacement required for 3 years (Okuma equipment actual data) |

Note: To use a sludgeless tank, you must select a chip conveyor with a drum lter.

The spindle lineup

For highly efficient machining of general machine parts

Standard spindle No. 40

- Spindle speed: 15,000 min-1

- Max output: 38/18.5 kW (40%ED /cont)

- Max torque: 242/148 N-m (20%ED /cont)

Material : S45C actual data

Chips: 483cm3/min (Face milling, S45C)

704cm3/min (End milling, S45C)

| Tool | Spindle speed min-1 |

Cutting m/min |

Feed rate mm/min |

Cut width mm |

Cut depth mm |

|---|---|---|---|---|---|

| ø100 face mill 7 blades (carbide) |

955 | 300 | 2,300 | 70 | 3 |

| ø20 roughing end mill 7 utes (carbide) |

4,000 | 251 | 8,800 | 40 | 20 |

Material : A5052 actual data

Chips: 4,022cm3/min (Face milling, A5052)

4,340cm3/min (End milling, A5052)

| Tool | Spindle speed min-1 |

Cutting m/min |

Feed rate mm/min |

Cut width mm |

Cut depth mm |

|---|---|---|---|---|---|

| ø63 face mill 5 blades (carbide) |

8,000 | 1,583 | 12,000 | 44 | 7.6 |

| ø25 roughing end mill 3 utes (carbide) |

8,000 | 628 | 8,000 | 15.5 | 35 |

Note: The “actual data” referred to above for this brochure represent examples, and may not be obtained due to differences in specifications, tooling, cutting condition, and others.

For fast machining of aluminum

High-speed spindle No. 40 for aluminum applications

(option)

- Spindle speed: 20,000 min-1

- Max output: 43/22 kW (15%ED /cont)

- Max torque: 137/54 N-m (10%ED /cont)

For powerful cutting of castings and cast steel parts

Power spindle No. 40 (option)

- Spindle speed: 12,000 min-1

- Max output: 38/26 kW (40%ED /cont)

- Max torque: 302/148 N-m (10%ED /cont)

Highlighted Specs

| Item | Unit | MA-4000H | |

|---|---|---|---|

| Pallet | Pallet size | mm (in) | 400 × 400 (15.75 × 15.75) |

| Max load capacity | kg (lb) | 400 (880) | |

| Max workpiece dimensions | mm (in) | ø630 × 900 (ø24.8 × 35.43) | |

| Spindle | Spindle speed | mm-1 | 15,000 [12,000、20,000] |

| Tapered bore | 7/24 taper No.40 [HSK-A63]*1 | ||

| Feed rate | Rapid traverse | m/min (ipm) | X, Y, Z: 60 (2,362) |

| ATC | Tool shank | MAS403、BT40 [CAT40、DIN40、HSK-A63]*1 |

|

| Pull stud | MAS2 [MAS1、CAT、DIN、JIS] | ||

| Magazine capacity | tools | 48*2 [64]*2 [140、180、220、260、300、340]*3 |

|

| Motors | Spindle | kW (hp) | 38/18.5 (51/25) [12,000 min-1:38/26 (51/35)] [20,000 min-1:43/22 (57/29)] |

| Machine Size | Height | mm (in) | 2,750 (108.27) |

| Floor space; width × depth (RDF specs)*4 | mm (in) | 2,300 × 5,065 (90.55 × 199.41) | |

| Mass | kg (lb) | 11,000 (24,200) | |

| Controller | OSP-P500M |

[ ]: option

*1. 20,000min-1 with HSK-A63 only

*2. Disk magazine

*3. Matrix magazine

*4. With RDF drum lter-type lift-up chip conveyor