PRODUCTS

Improve productivity

-

- Productivity increases with compact, high-speed operations

-

Compared to the previous model, productivity improves with faster feed rates for each axis, for even higher productivity.

Installation width: 1,400 mm (GENOS L250Ⅱ). The highly rigid structural design supports powerful cutting loads to offer high productivity.

-

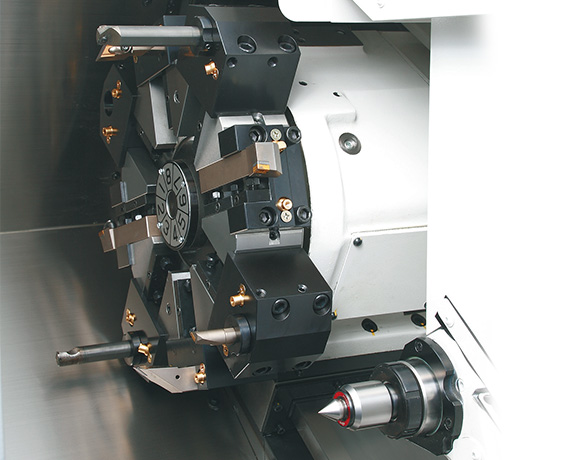

- Turret (turning operations)

- V8 and V12 turrets are available.

Boring bars up to ø32 mm or ø40 mm can be attached.

Ease of use in any shop floor was a thoroughly pursued objective

-

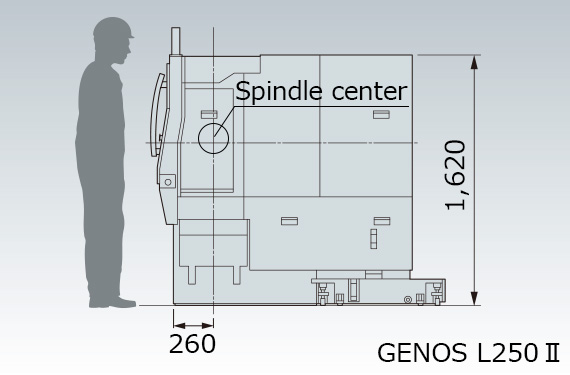

- Structurally designed with good accessability

- The spindle centerline is just 260 mm from the front of the machine for easy access and reduced operator workload. The low 1,620-mm machine height also allows operators to easily see other machines and operators nearby.

-

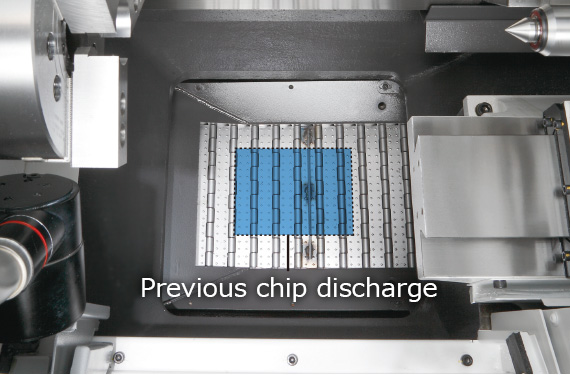

- Outstanding chip discharge

- The chip discharge outlet is 1.8 times larger than on previous machines, minimizing chip accumulation. The cleaning frequency is reduced for maximum operation time.

-

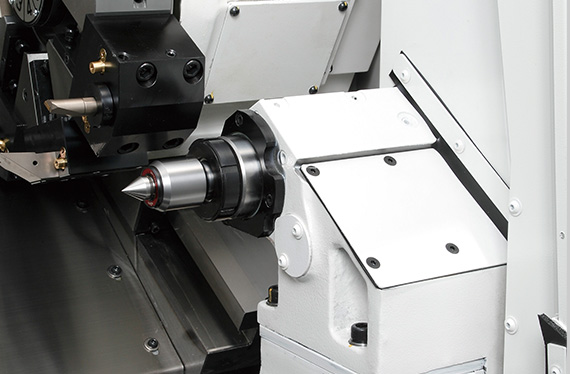

- Hydraulic headstock

- A high-rigidity, low center height hydraulic turret supports powerful, accurate machining.

-

GENOS L250Ⅱ MT No.4 (revolving center)

-

- Easy maintenance of the coolant tank

- The separated coolant tank can slide out and be cleaned without removing the chip conveyor. In addition, the tank can be washed in the provided maintenance space, resulting in minimal machine installation space.

Mass production lines also compact

-

- Ready-to-go systems for 1-machine 1-loader applications to full-scale production lines

- Your best layout for automation

- Get outstanding flexibility from 1-machine/1-loader to multi- machine lines, with optimum cycle times, operation mix, work flow, floor space and the like.

Okuma's selection of work tables, part turnover stands, post- process gauges and other peripherals, can provide an ideal system arrangement to meet your needs.

-

Specifications may vary in different markets.