PRODUCTS

Watch the videos

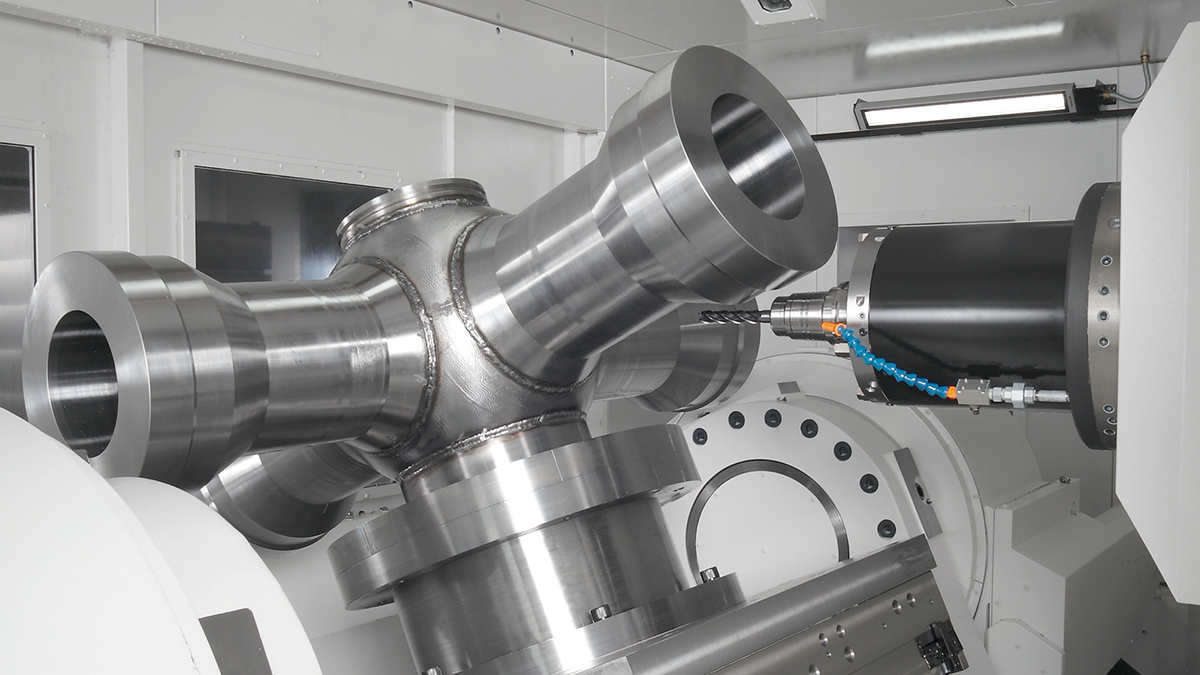

- Titanium structural part

- This demonstrations shows contour milling, drilling, pocket milling as well as 5-axis corner finishing.

- Heavy-duty machining

- Stable and powerful machining of difficult-to-cut materials. Heavy-duty machining can be performed using five simultaneous axes.

Experience the power of process-intensive machining with 5-axis multitasking

Highly rigid machine structure

Bed and column to achieve heavy-duty cutting

- Ideal rib layout to resist bending and torsion

Accurate, powerful, and highly accurate axis drive system

- High accuracy double ball screws are used on X, Y, and Z axes

- Double motor drive system on A, B axes

Thermal deformation controlled for high-accuracy machining

- Ball screw and motor base cooling on X, Y, Z axes

- A, B axis drive unit cooling

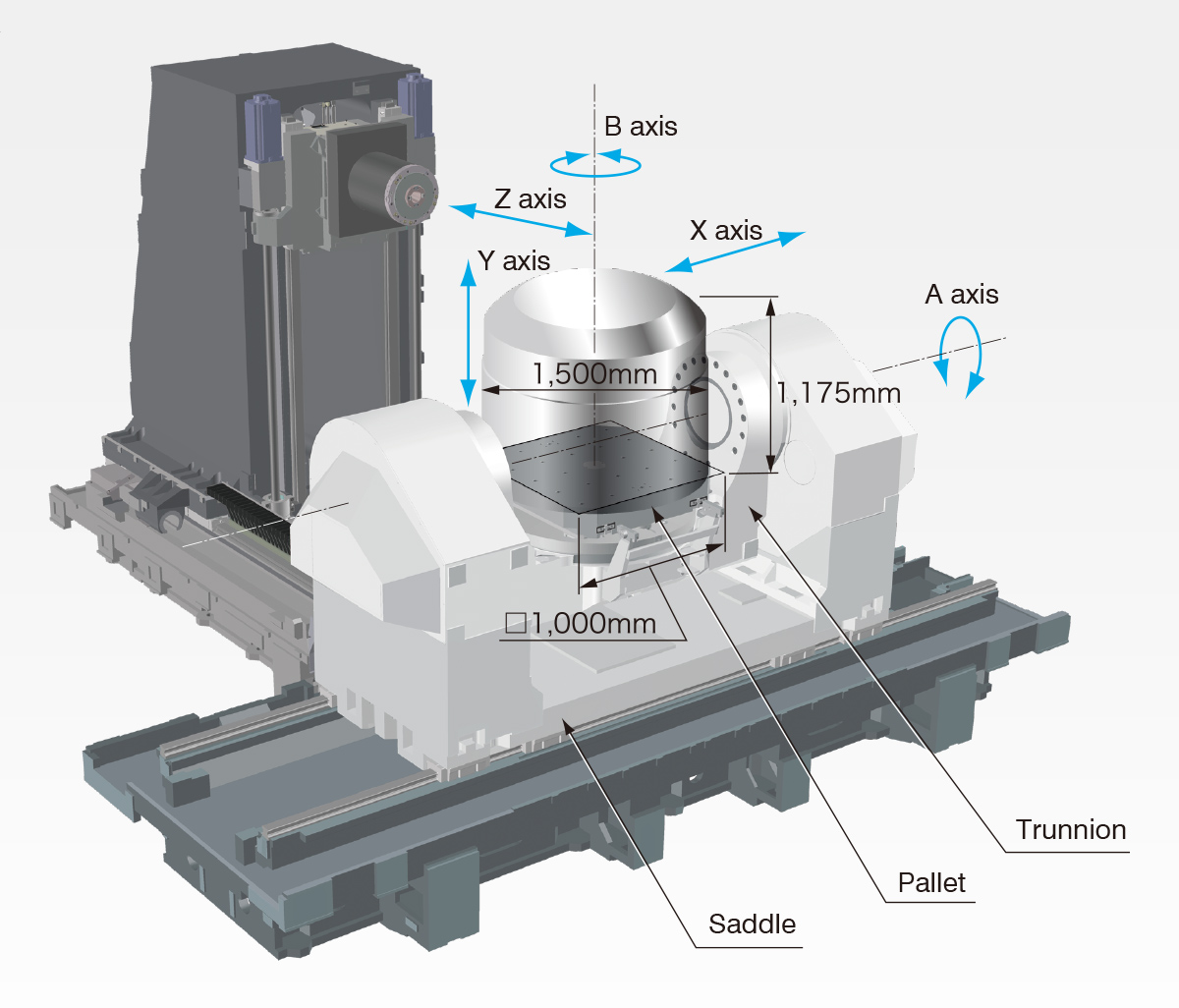

Trunnion table that supports high speed, high accuracy machining of large parts

Swing ranges

- A axis (table swing)

+35 to −115° - B axis (pallet swing)

360°

Max workpiece

- Max workpiece swing diameter

ø1,500 mm - Max workpiece height

1,175 mm - Max workpiece weight

2,500 kg

Pallet size

- 1,000 × 1,000 mm

Axis travel

- X: 1,550 mm

- Y: 1,600 mm

- Z: 1,650 mm

Highly efficient machining with outstanding machining capacity

Beefy torque makes easy work even of difficult-to-machine material

- Integral motor/spindle: 1,071 N-m

- Gear spindle: 1,920 N-m (Optional)

Machining capacity

Gear spindle: 4,500 min-1, 40/30 kW (15 min/cont) (Optional)

| Tool | Stock removal cm3/min |

Spindle speed min-1 |

Cutting speed m/min |

Width × depth mm |

Feedrate mm/min |

|---|---|---|---|---|---|

| ø250 face mill, 10 blade (cermet) |

1,000 | 293 | 230 | 175 × 6 | 953 |

| ø63 end mill radial facing, 4 blade (carbide) |

602 | 1,415 | 280 | 10 × 35 | 1,720 |

| ø50 end mill radial facing, 3 blade (carbide) |

700 | 1,780 | 280 | 50 × 10 | 1,400 |

(material S45C)

* The above are actual examples. Your results may vary due to differences in specifications, tooling and cutting conditions.

Highlighted Specs

| Item | Unit | MU-10000H |

|---|---|---|

| Pallet size | mm(in) | 1,000 × 1,000 (39.37 × 39.37) |

| Max workpiece dimensions | mm(in) | ø1,500 × 1,175 (ø59.06 × 46.26) |

| Spindle speed | min-1 | 6,000 |

| Tool storage | tools | 81 |

| Motor | kW(hp) | 45/37 (20 min/cont) (60/50) |

| Machine size (W × D × H) |

mm(in) | 6,880 × 10,930 × 3,694 (270.87 × 430.31 × 145.43) |