- HOME

- Technology & Solutions Solutions by industry

- Automotive industry

- Car body component Headlight mold (Other)

OtherCar body component

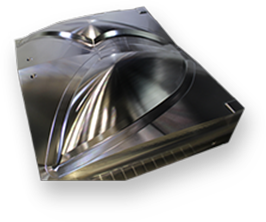

Headlight mold

Resin mold for headlights

Material: FC300

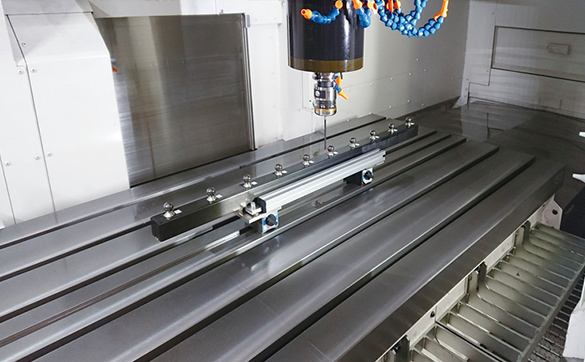

Completing machining of large die/mold with one machine

Significantly reducing production lead time

POINT 01

- Rough to finishing machining are completed on one machine

-

- Cutting time is shortened by using a high power spindle to achieve high-efficiency roughing

- High-quality finishing of molds

Hyper-Surface automatically compensates disturbances within the part program

Hand-finishing time is reduced by improving the surface quality of molds

Finishing machining

POINT 02

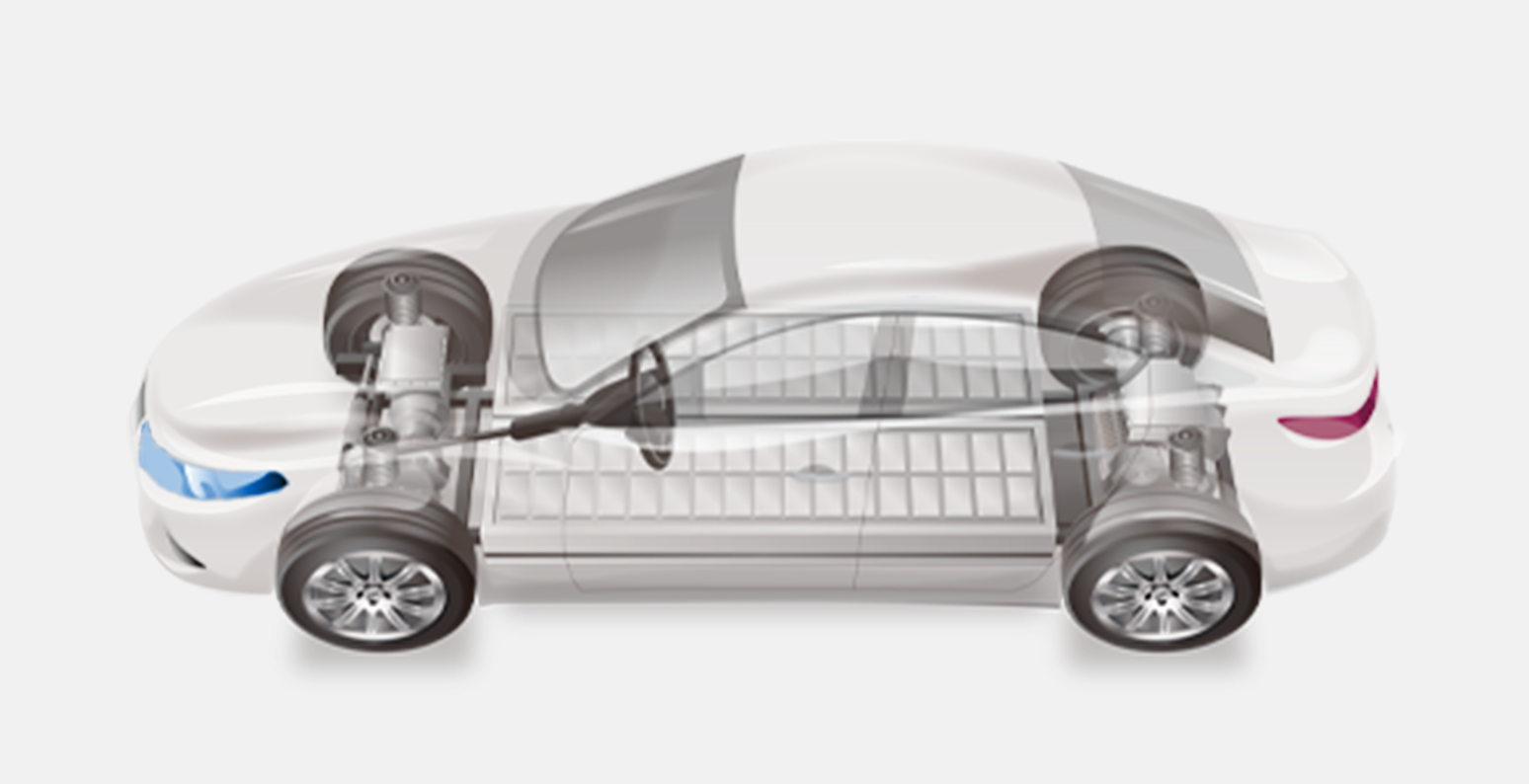

- High measurement and machining accuracy is maintained

-

- Accuracy Stability Diagnosis Function allows the machine to self-diagnose changes in machining accuracy, and is visualized for the machine operator

The effects that change in room temperature has on machining accuracy is visualized, ensuring the reliability the machine's measurement and machining abilities - 3D Smart Calibration System to calibrate the volumetric accuracy of the machine

High measurement and machining accuracy are ensured through periodic inspection and calibration of machine accuracy - The machine autonomously maintains high accuracy in a stable manner with the Thermo-Friendly Concept

Compensations are made with consideration of the expansion and contraction of workpieces, in addition to the thermal deformation of the machine

This enables conducting highly accurate measurement and machining within a typical factory environment

- Accuracy Stability Diagnosis Function allows the machine to self-diagnose changes in machining accuracy, and is visualized for the machine operator