PRODUCTS

- Wide Y-axis travel balanced with excellent workability

- Ideal work envelope for medium and large-size parts machining

-

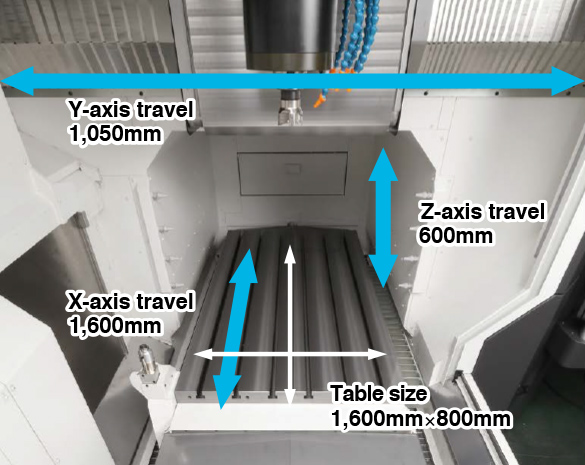

Y-axis travel : 1,050mm

For medium and large parts, and large plastic mold manufacturing, with 800mm table, and 1,050mm Y-axis travel

Best-in-class floor space productivity- X-axis travel : 1,600mm

- Y-axis travel : 1,050mm

- Table size : 1,600×800mm

- Outstanding table and spindle access provide excellent workability

-

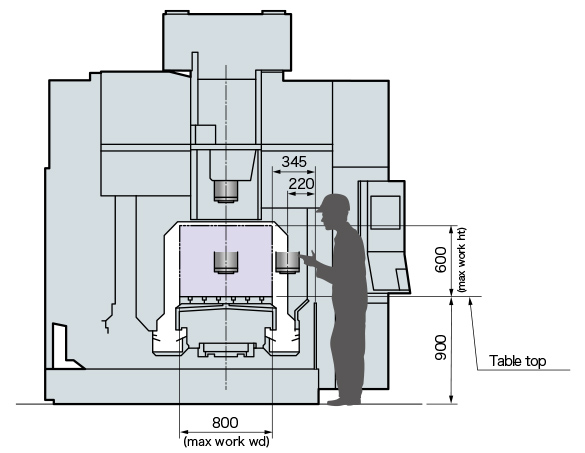

Easy access to table and spindle

- Access to spindle : 220mm

- Access to table : 345mm

- Table height : 900mm

- Front door opening : 1,620mm

-

Max workpiece

- Size : 1,600 × 800 × 600mm (L × W × H)

- Load mass : 2,500kg

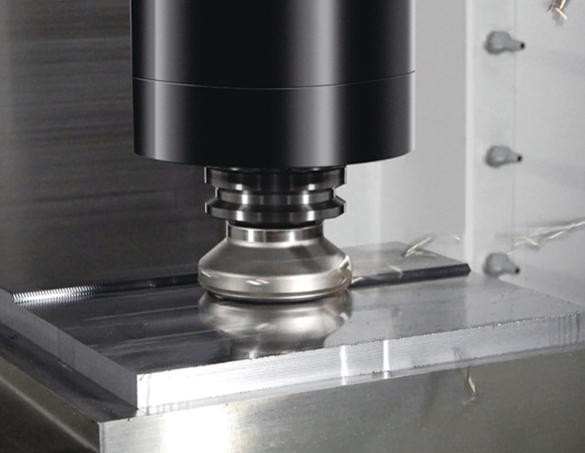

- Highly efficient machining of die/mold and

semiconductor manufacturing equipment parts

- Wide spindle lineup provides the right match for general machinery

to die/mold and aluminum parts applications -

Wide-range spindle (No.40)

Highly efficient general machine part applications

- Spindle speed : 15,000min-1

- Max output : 26/18.5kW (10 min/cont)

- Max torque : 199/146N - m (5 min/cont)

| Tool | Spindle min-1 |

Cutting m/min |

Feed rate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

|---|---|---|---|---|---|---|

| ø100 face mill 5 blades (carbide) |

955 | 300 | 1,429 | 70 | 4 | 400 |

| ø50 insert drill |

606 | 95 | 90.9 | - | - | - |

| Tap M30P3.5 |

240 | 23 | 840 | - | - | 84%(Spindle load) |

(material : S45C)

| Tool | Spindle min-1 |

Cutting m/min |

Feed rate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

|---|---|---|---|---|---|---|

| ø63 face mill 5 blades (carbide) |

15,000 | 2,969 | 8,523 | 44 | 4 | 1,500 |

(material : A5052)

-

High-speed spindle (No.40)

Mainly for aluminum (Optional)

- Spindle speed : 20,000min-1

- Max output : 30/22kW (10 min/ cont)

- Max torque : 57/42N - m (10 min/ cont)

-

Power spindle (No. 40/50, roller bearings)

Roughing and finish of dies&molds(Optional)

- Spindle speed : 12,000min-1

- Max output : 33/26kW (10 min/ cont)

- Max torque : 302/148N - m (10% ED/cont)

| Tool | Spindle min-1 |

Cutting m/min |

Feed rate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

|---|---|---|---|---|---|---|

| ø100 face mill 5 blades (carbide) |

955 | 300 | 1,910 | 70 | 5 | 669 |

| ø20 roughing end mill, 7 flutes (carbide) |

4,000 | 251 | 9,520 | 20 | 3.7 | 704 |

(No. 50 high power spindle, material: S45C)

Delivering longer unattended operations

Large amounts of aluminum chips also cleanly removed

- Wide in-machine chip conveyor

- Crossrail shower system (Optional)

- In-machine vertical covers prevent chip accumulation

Large chip volumes discharged smoothly

- “Working with temperature changes”

Thermo-Friendly Concept -

The “Thermo-friendly” concept enables remarkable machining accuracy through original structural design and thermal deformation control technology.

If frees you from troublesome dimensional compensation and warm-up. Exhibits excellent dimensional stability even during consecutive operation over long periods and environmental temperature change in the plant.

- Achieving high die/mold surface quality machining

Hyper-Surface (Optional) -

Auto machining data compensation, easy and improved die/mold surface quality

Modifying CAM machining data is not required.

Ridgelines and uneven surface edges are reduced,the machined surface quality is improved, and hand-polishing times are eliminated. In addition to the Sculptured-Surface Adaptive Acceleration Control featured in the previous Super-NURBS function, the new Hyper-Surface — while maintaining the required shape accuracy — automatically compensates for those edges and adjacent cutter path positioning errors caused by remnants of “disturbances” found in the CAM machining data.

Highlighted Specs

| Item | Unit | MB-80V |

|---|---|---|

| Table size | mm (in) | 1,600 × 800 (62.99 × 31.50) |

| Spindle speed | min-1 | 15,000 / 12,000 |

| Tool storage | tools | 32 |

| Motor | kW (hp) | 26/18.5 (35/25) (10 min/cont) 33/26 (44/35) (10 min/cont) |

| Machine size (W × D × H) |

mm (in) | 4,500 × 2,970 × 3,320 (177.17 × 116.93 × 130.71) |