- HOME

- Okuma Technology Premium Solutions

- Hyper-Surface

Okuma Technology Premium Solutions

Auto machining data compensation, easy and improved die/mold surface quality

Hyper-Surface, in addition to the Sculptured-Surface Adaptive Acceleration Control featured in the

previous Super-NURBS, detects CAM-output machining data “disturbance,” and corrects that on the

Okuma CNC to improve surface quality while maintaining the required shape accuracy.

- Production floor issues

- Machining data command-point

disturbance adversely affects

surface quality -

- ・Machining data variations result in scratches on the machined surface.

- ・Correcting the supplied data is difficult.

- ・Removing cutter marks by hand finishing and polishing is time consuming.

- Machining data command-point

- User benefits

- Better surface quality without modifying the machining data

-

- ・Eliminates the time required for hand finishing.

- ・Reduce scratches and uneven edges.

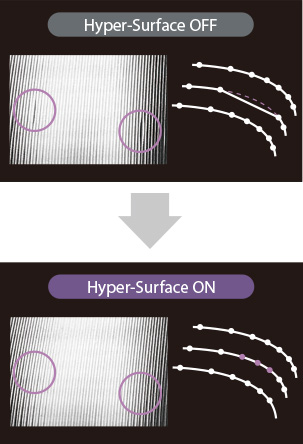

Eliminating variations in command position and feed rate improve machined surface quality

Automatically corrects for small variations in machining data command positions of output from a CAM processor.

And passing speeds for each cutter path at corners are made consistent.

That stabilizes feed rates and improves surface quality.

| Conditions | Tool | Spindle speed [min-1] |

Feed rate [mm/min] |

Pick feed [mm] |

Cutting depth [mm] |

|---|---|---|---|---|---|

| Scan-line machining |

ø10-mm ball end mill |

15,000 | 6,000 | 0.2 | 0.1 |

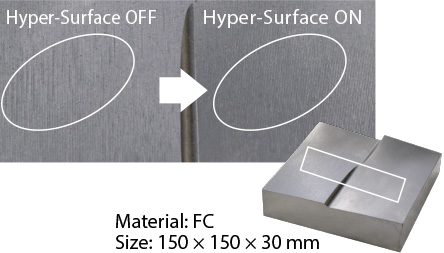

Aligning adjacent cutter paths, reducing ridges

Correcting uneven spaces between adjacent cutter paths, and reducing inconsistent valley depths and edge widths.

| Tool | Spindle speed [min-1] |

Spindle feed rate [mm/min] |

Pick feed[mm] | Depth of cut [mm] |

|---|---|---|---|---|

| ø30-mm ball end mill |

10,000 | 5,000 | 0.5 | 0.1 |