-

01 Capabilitiesof 5-axis machining

01 Capabilitiesof 5-axis machining

centers and

multitasking machines -

02 Why Okuma is chosenOkuma, a manufacturer of

02 Why Okuma is chosenOkuma, a manufacturer of

5-axis machining centers

and multitasking machines -

03 Case studiesof installing 5-axis

03 Case studiesof installing 5-axis

machining centers and

multitasking machines. -

04 Lineupof 5-axis machining

04 Lineupof 5-axis machining

centers and

multitasking machines -

05 Q&Aabout 5-axis machining

05 Q&Aabout 5-axis machining

centers and

multitasking machines

01

Capabilitiesof 5-axis machining centers and multitasking machines

Setup and other machining

preparations are

time-consuming and lead to

a shortage of manpower.

Inconsistencies in

machining precision make

it difficult to meet

required accuracies.

Looking to machine

complex-shaped

parts more

efficiently.

5-axis machining centers and multitasking machines provide solutions to these challenges and concerns.

This is why they are trusted in machining shops.

“Understanding process-intensive machining”

- Benefit 1

- Reducing production

lead time

- Benefit 2

- Enhancing productivity

while reducing labor

requirements

- Benefit 3

- Reducing the risk of

accuracy degradation

[A Beginner’s Guide to 5-Axis Machining Centers

and Multitasking Machines]

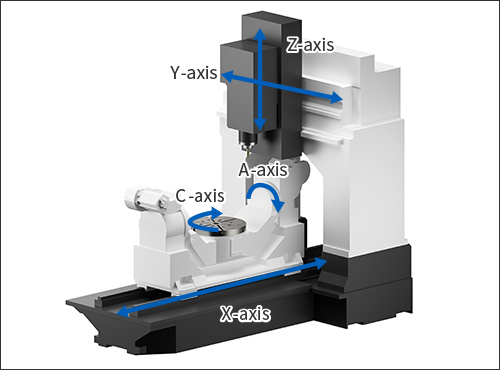

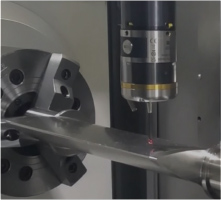

What is a 5-axis machining center?

A machining centerequipped with 3 linear axes and 2 rotary axes

- Fundamental structure of a 5-axis machining center

-

- A machining center with 2 additional rotary and tilting axes, complementing the XYZ linear axes (3 linear axes). The additional rotary axes enable multi-surface machining in a single setup.

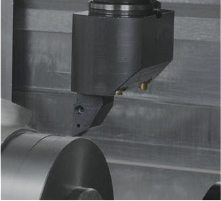

- In 5-axis machining, tilting tools or workpieces allows for machining with shorter tools. Increased tool rigidity ensures stable machining.

- Depending on the use of the additional two axes, machining methods are categorized into indexed 5-axis machining and simultaneous 5-axis machining.

Indexed 5-axis machining

or

Simultaneous 5-axis machining

With two machining methods, the machine easily handles

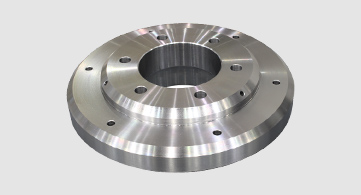

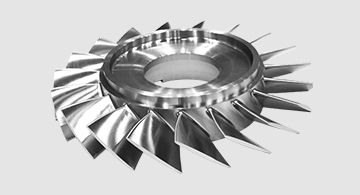

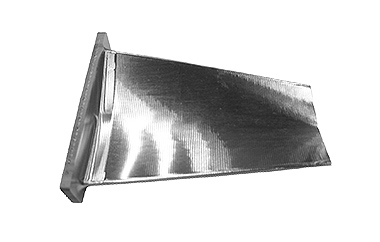

workpieces with complex shapes

Indexed 5-axis machining

The two rotary axes adjust the angle and machining is performed using the three linear axes

Multi-sided machining

Simultaneous 5-axis machining

Machining is performed with all five axes moving simultaneously

Machining of free-form surface

5-axis machining centersBenefits

Shorten production lead time by reducing setup and transportation time

Save labor by reducing the number of setup operations

Reduce running costs, including electricity

Minimize accuracy inconsistencies by machining multiple surfaces in a single setup

Adapt flexibly to changes in the types and quantity of parts that need to be machined by utilizing a variety of tools

Improve surface quality by shortening tool projection length

Reduce jig costs

Open up new possibilities for machining shops by shortening production lead time, saving labor, and reducing the risk of accuracy degradation

What is a multitasking machine?

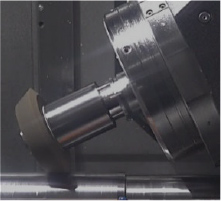

A machine tool equipped with an automatic tool changer (ATC)and capable of machining processes such as turning and milling

It can perform a wide variety of machining operations using many tools

Turning

Milling

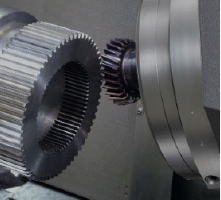

Gear Machining

Grinding

Gauging

Turning of sloped axes, machining of gears, and machining of other complex-shaped workpieces are also possible

Multitasking MachineBenefits

Shorten production lead time by reducing setup and transportation time

Save labor by reducing the number of setup operations

Reducing equipment installation costs

Reduce running costs, including electricity

Saving space by eliminating the need to install multiple machines

Minimizing variations in accuracy by performing multiple processes in a single chucking process

Adapt flexibly to changes in the types and quantity of parts that need to be machined by utilizing a variety of tools

Open up new possibilities for machining shops by shortening production lead time, saving labor, and reducing the risk of accuracy degradation