-

01 Capabilitiesof 5-axis machining

01 Capabilitiesof 5-axis machining

centers and

multitasking machines -

02 Why Okuma is chosenOkuma, a manufacturer of

02 Why Okuma is chosenOkuma, a manufacturer of

5-axis machining centers

and multitasking machines -

03 Case studiesof installing 5-axis

03 Case studiesof installing 5-axis

machining centers and

multitasking machines. -

04 Lineupof 5-axis machining

04 Lineupof 5-axis machining

centers and

multitasking machines -

05 Q&Aabout 5-axis machining

05 Q&Aabout 5-axis machining

centers and

multitasking machines

03

Case studies of installing 5-axis machining centers and multitasking machines.

Synthemec Co., Ltd

- Employees: 78

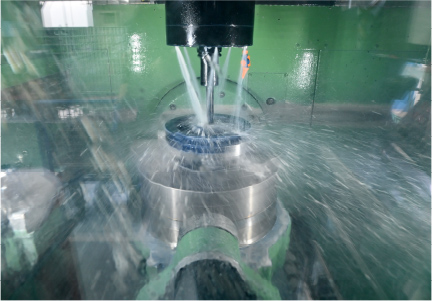

- 5-Axis Vertical Machining Center

- MU-8000V-L

Hope Industry

- Employees: 66

- 5-Axis Vertical Machining Center

- MU-5000V 2-pallet APC specification

Nabeya Bi-tech Kaisha

- Employees: Approx 400

- 5-Axis Vertical Machining Center

- MU-4000V-L/MU-5000V-L

Here are case studies of customers who have installed 5-axis machining centers and multitasking machines.

Use these as case studies to assist in problem-solving

Synthemec Co., Ltd

Lead time for high-mix, low-volume production of ø500–ø1,000 mm parts reduced by 50%.

Machine that autonomously performs high levels of 5-axis machining

We do design, parts machining, assembly, and development of controls for the automatic labor-saving equipment we produce. We have established an integrated process. The equipment we produce comes in a variety of sizes, and its components are manufactured in high-mix, low-volume quantities. For machining parts in the ø500–ø1,000 mm range, we did not have a machining center with the appropriate table size. As a result, we had to split the process between turning and machining, and sometimes outsourced part of the work. We decided that installing a 5-axis machining center suitable for this size range would not only shorten lead time through process integration, but also reduce the cost and time required for outsourcing.

Given these circumstances, what made you choose Okuma?

Taking the necessary machining range into account, we chose the MU-8000V-L. The machine's rigidity enables both heavy-duty cutting and high-accuracy machining. Our main goal was to install a machine that could manufacture workpieces in the ø500 to ø1,000 mm size range, where there had been difficulties at times for insourcing. In addition to covering this size range, a major factor in choosing the MU-8000V-L was its turning capability that is equal to that of an Okuma lathe. Our existing MU-500V III is a 5-axis machining center capable of machining workpieces up to ø700 mm. By adding the MU-8000V-L, we can significantly expand our machining range, which will contribute in providing higher-value contracted machining as well as improving the production of automatic labor-saving equipment. We were also drawn to features such as the 5-Axis Auto Tuning System, which allows geometric errors in 5-axis machining centers to be corrected easily and thereby improving machining accuracy. Another goal was to create an environment that made it easier for younger operators to take on 5-axis machining.

Lead time reduced by approximately 50% through process integration

Now that you have installed the MU-8000V-L, how would you rate its productivity and ease of use?

Previously, ø500–ø1,000mm-sized parts were first turned on an NC lathe or a large multitasking machine before being machined on a machining center. With the installation of the MU-8000V-L, both turning and milling can be completed on the same machine. As a result—when accounting for preparation work, accuracy checks, and workpiece transfer associated with setup changes—we were able to reduce production lead time by approximately 50%. Before installation, we had some concerns about the machining capability of a complex 5-axis system and about the possibility of variations in accuracy occurring during long-run operations. However, after operating the MU-8000V-L, we found that its machining capability is equal to that of our existing #50 taper 3-axis machining centers. Its stability in machining accuracy is excellent, and we can clearly feel the machine’s high rigidity. Furthermore, dimensional stability is retained at high levels thank to the Thermo-Friendly Concept —just like other Okuma machines—and requires almost no correction work even during Hokkaido’s harsh winters, when temperatures drop below zero. Previously, we had to calculate the coefficient of thermal expansion of workpieces in advance to ensure machining accuracy. Eliminating this task has allowed us to use more time on other tasks. In addition to this, the 5-Axis Auto Tuning Function (option) automatically measures and corrects geometric errors with a single push of a button. The tuning process itself only takes about 10 minutes (in full-mode settings). Because the adjustments are highly accurate, we can use the system with confidence. It frees us from time-consuming measurement and correction tasks, and has significantly reduced machine downtime.

Thank you very much.

Hope Industry

Advancing into new fields utilizing manufacturing expertise gained through machining of precision parts for semiconductors

The MU‑5000V: optimized for high‑mix, low‑volume production

Please share why you decided to install a 5-axis machining center.

Our 3‑axis vertical and horizontal machining centers have enabled prototype and precision‑parts machining, but the global surge in semiconductor demand has left us operating at maximum capacity.

Times like these call for acquiring new technologies and making investments to secure future growth.

When we solicited ideas and opinions from the shop floor, one proposal stood out. It was to install a 5‑axis machining center to take on more advanced machining challenges.

Given these circumstances,

what made you choose Okuma?

Although we had high expectations for integrating multiple processes into one machine, we were concerned about the complexity of programming, the difficulty of interference checks, and about the risks of machine stoppages caused by collisions.

Nevertheless, with an eye on our next stage of growth, we pushed ahead with the installation plan of the two-pallet APC configuration after realizing the need to boost productivity by raising our capability to do more unmanned operation.

During model selection, we compared 5-axis machines from Okuma and two other suppliers, and ultimately selected the MU-5000V.

By integrating multiple machining processes into a single machine, time used for setup change was reduced by 35 percent

Consistent dimensional stability and high machining performance—even in 5-axis machining

Now that you have installed the MU-5000V, how would you rate its productivity and ease of use?

With 3-axis machines, each step is split across several setups, so every setup change consumes time and effort. A 5-axis machine can integrate those steps into one machine, allowing us to complete multiple processes within a one-chucking setup which dramatically lightens the workload.

In particular the MU-5000V can handle workpieces requiring angled holes or back-side chamfers in a single-chucking operation, greatly improving overall efficiency.

Because 5-axis machines have more complex kinematics, we expected the effects of thermal deformation to make tight-tolerance work difficult. However, thanks to Okuma's Thermo-Friendly Concept, the MU-5000V delivers the same dimensional stability as our 3-axis Okuma models and requires virtually no thermal-related compensation work.

We have also experienced its outstanding machining capability—it is a machine that cuts exceptionally well.

Components for semiconductors require to have exceptional surface quality. Hyper-Surface Ⅱ automatically corrects tool marks and edge unevenness caused by CAM data, resulting in improved machined surface quality.

Having the idea of doing long hours of unmanned operations overnight in the future, we equipped the machine with a 2-pallet APC configuration which allows workpiece setup to be done even while the machine is running. This is to enable us to increase machine utilization and meet the to meet the growing demand for semiconductor related parts.

Thank you very much.

Nabeya Bi-tech Kaisha

The effort required for additional machining of pulley shaft holes has been dramatically reduced, boosting productivity

Please share why you decided to install a 5-axis machining center.

We manufacture power transmission pulleys (castings) used in blowers and commercial air conditioners. We also provide a “shaft hole additional machining service”, which is an additional service to machine shaft holes, screw holes, and keyways to the workpiece. Within a day, machining process is done and product is shipped out. For 30 years, we relied on three machine tools, including a lathe and an in-house-built special-purpose machine, to perform pilot hole drilling, turning, and screw tapping. However, the numerous processes and the need for skilled labor for tasks like diagonal hole machining made it challenging to reduce time. We concluded that investing in a 5-axis machining center was essential to boost productivity.

Given these circumstances, what made you choose Okuma?

While comparing the performance and features of 5-axis machines on the websites of various machine tool manufacturers, my boss encouraged me to visit Okuma and see the machines in person. Therefore, we visited Okuma to thoroughly examine the machining precision, range, and cycle time, as well as operability and ease of use.

In addition to its high basic performance, what stood out to us was the excellent accessibility to the machine, which eliminates the need for climbing stairs. We were particularly concerned about other manufacturers' machines, which required workers to go up and down stairs during setup, creating additional strain for them. Another feature that caught our attention was the collision avoidance system. We were convinced that this feature would significantly reduce preparation time by eliminating the need for operators to perform interference checks on the actual machine. Additionally, we found it highly appealing that measurement results of machining accuracy, maintenance information, and operation manuals could be easily checked on the large operation screen.

Furthermore, since we plan to utilize the machining center not only for additional shaft hole machining but also for custom product manufacturing in the future, we determined that Okuma's 5-axis vertical machining center "MU-V" was the optimal choice. This decision was based on a comprehensive evaluation of machining quality, workability, cost, applicability, and other factors.

Machining that previously required three machines is now completed by a single machine.

Machining time has been reduced to around 1/2 to 1/3, and machining productivity has approximately doubled.

Now that you have installed the MU-4000V-L and MU-5000V-L, how would you rate their productivity and ease of use?

The preparatory hole drilling, lathe machining, and drilling machine operations, which previously required three separate machines, can now be completed by a single MU-V machine. This has halved the machining time per piece from 15–20 minutes to 5–10 minutes. As a result, the daily production limit, which was previously capped at 35 pieces, has increased to approximately 60 pieces.

The improved accessibility of the machine has also reduced the operator's strain, making setup work much easier and more efficient.

In addition, the “3D Virtual Monitor” enables us to check for interference on a PC in advance, significantly reducing preparation time before actual machining. The operation screen of the “Collision Avoidance System” also allows us to check for interferences in advance, eliminating the risk of collisions. This has made first-part machining, which previously required a slower feed rate, much more efficient. Maintenance information is also accessible through the OSP, with maintenance and inspection schedules clearly visualized. This ensures proper machine maintenance, helping to prevent breakdowns and unexpected shutdowns.

Thank you very much.

Shirakawa Co., Ltd

- Employees: 47

- Multitasking Machine

- MULTUS B300Ⅱ/MULTUS B750

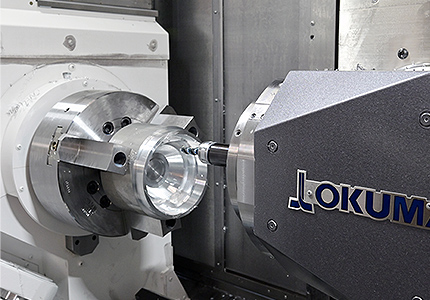

Yoshida Tekkousho Co., Ltd

- Employees: 5

- Multitasking Machine

- MULTUS U3000

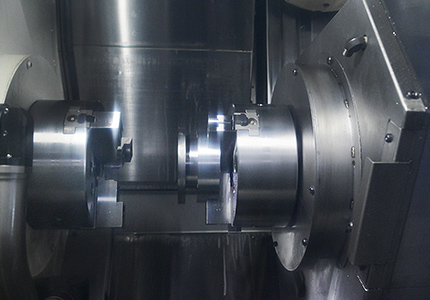

Tamatec Co., Ltd

- Employees: 100

- Multitasking Machine

- MULTUS B300Ⅱ (Sub spindle Spec)

KINREI MACHINERY CO., LTD.

- Employees: 79

- Multitasking Machine + Built-in Robot

- MULTUS B300Ⅱ ARMROID

Here are case studies of customers who have installed 5-axis machining centers and multitasking machines.

Use these as case studies to assist in problem-solving

Shirakawa Co., Ltd

High-mix, low-volume production of high-accuracy large shafts

Expanding business into the seismic isolation device market with the MULTUS multitasking machine

Please share why you decided to install Multitasking Machines

We manufacture ball screw shafts, which enable high-accuracy feeding and positioning in precision machinery, industrial robots, LCD production equipment, and semiconductor manufacturing equipment. We also produce complex nut components with built-in balls. Since ball screws are critical components that determine the basic performance of the final product, strict dimensional tolerances are required, and high-mix, low-volume production with short delivery times is not uncommon.

Previously, the machining process was divided into separate turning and milling operations, which required significant time and effort for changeovers and setup, and often resulted in variations in machining accuracy. To address these issues, we sought to introduce a multitasking machine capable of completing all machining in a single chucking operation, thereby consolidating processes and strengthening QCD—quality, cost, and delivery.

What made you choose Okuma?

It is extremely important that the phase alignment between thread turning and milling operations are precise during the production process. With this in mind, a multitasking machine eliminates concerns about phase misalignments because both operations can be performed in a single chucking operation. We therefore considered installing the MULTUS B300II (sub-spindle specification) for machining nut components used in ball screws. Previously, machining was performed in two separate processes—turning and milling. However, with the sub spindle, the handover of workpieces is automated and enables machining to be completed in a single cycle. This has eliminated variations in machining accuracy and has reduced lead time. At the same time, we also considered the MULTUS B750 (with a 4,000 mm distance between centers) for machining large shafts, which are our flagship products. A decisive factor was its capability to machine workpieces up to ø1,050 mm in diameter and 4,000 mm in length, while maintaining long-term stable machining accuracy. Thermal displacement control is typically difficult with large machines, so being able to maintain stable accuracy was very important. Combined with the machine's high rigidity that enables to cut high-hardness material with ease, we chose the MULTUS B750.

Achieving a 100% on-time delivery rate and a defect rate of just 0.2%

'How does the MULTUS contribute to QCD, and how do you feel about its usability?

The MULTUS made process integration possible, allowing us to shorten lead time and achieve an on-time delivery rate of nearly 100%. In terms of quality, we have maintained a defect rate of 0.2% based on material cost. Supporting this achievement is our company-wide quality control system and well-organized plant environment, as well as the elimination of machining accuracy variation and excellent dimensional stability against thermal displacement made possible by the MULTUS series.

In the past, collisions sometimes occurred even when we believed we had carefully checked movements and interference. This resulted in machine stoppages, repairs, and delivery delays. However, with the standard-equipped Collision Avoidance System, we can run machining simulations in advance, and the axes automatically stop before a collision occurs—even if there is a program input error. This provides exceptional peace of mind and greatly reduces the psychological burden on operators. Even for first-article machining, preparation time has been significantly reduced.

Thank you very much.

Yoshida Tekkousho Co., Ltd

By insourcing machining processes that were previously outsourced, both high productivity and high accuracy could be achieved.

Business expanded with the company's first MULTUS U3000 multitasking machine

Please share why you decided to install a Multitasking Machine

Mainly manufacturing machine tool parts, we have built a history of over 40 years with our turning craftsmanship that has been cultivated since the comany's founding. While planning out how to expand the company's customer base, orders for parts with complex geometries increased, which inevitably caused our outsourcing ratio for machining—the post-process after turning—to increase.

When my eldest son agreed to take over the family business, a management review of the company was done. The decision was made to grow the company into one that was capable of delivering high-value-added parts from start to finish by conducting machining processes internally. However, because there was a mountain of challenges—such as how to utilize the limited space within the factory, reducing workload of operators, and how to reduce running costs—we had repeated discussions about what kind of machine should be installed to enhance high-mix, low-volume production capabilities while achieving high productivity and labor-saving.

Given these circumstances, what made you choose Okuma?

Since the installation of a new model of machine is a significant capital investment that can affect management, selection of the model was undertaken with care. First, we let ten customers know that we were considering the installation of a 5-axis machining center or a multitasking machine and then asked them what kinds of parts they would order if we installed a new machine. The most common answer we recieved was "flange parts with a diameter of approximately ø400 mm". We also thought that since it would be our first installation of the machine, a familiar lathe-based multitasking machine would be more suitable for us than a 5-axis machining center. We considered multitasking machines of several machine tool manufacturers and ultimately determined that Okuma's MULTUS U3000 multitasking machine was the one that would enable us to perform optimal parts machining from a productivity perspective.

Productivity improved by more than 30% after installing the MULTUS U3000 and insourcing machining processes

Highest monthly sales recorded in the past 40 years

Now that you have installed the MULTUS U3000, how would you rate its productivity and ease of use?

Previously, we conducted turning in-house and outsourced post-processes that were done on a machining center. However, the MULTUS U3000 enables us to conduct all machining in a single-chucking process. As a result of incorporating machining in addition to turning, we are receiving more orders for high-value-added parts with complex geometries. Since we are able to deliver this kind of machining without outsourcing, it has a profound effect when we receive orders for large quantities. For example, when we received an order for 150 units of the same part in a particular month, once we made an NC program for it, all we had to do after that was to set the workpieces onto the machine. The end result was our monthly sales reaching a record high. It reduces the labor and time required for workpiece transportation, minimizes the workload of workers, but also lessens variations in accuracy. This has allowed us to increase productivity by more than 30%.

We receive many inquiries from new customers about new projects in which we are asked if the MULTUS U3000 can handle certain kinds of machining. Compared to before, the types of parts we can machine has increased by 20 to 25. An example of this is a prototype semiconductor-related components that required to cut stainless steel material to a thickness of 3 mm. Although it is not easy to machine such a part, accomplishing this could lead to a mass production order. We are focused on increasing our operation rate even further by fully utilizing the 40 ATC tools on the MULTUS U3000.

Thank you very much.

Tamatec Co., Ltd

Reducing setup and machining preparation time required when using a lathe and machining center to manufacture components, and eliminate accuracy variations during setup.

Please share why you decided to install a multitasking machine

We manufacture precision parts for industries such as aerospace, medical and optical equipment, and semiconductor manufacturing equipment. Many of these parts have complex geometries and are made from difficult-to-machine materials such as inconel and titanium alloys. All have strict dimensional tolerances and require to be machined within a 10-micron accuracy range. Before installing the MULTUS BⅡ series, we machined these parts using both NC lathes and machining centers. Accuracy becomes difficult to maintain when using several machines to machine a single component, but we made sure we always met each industries’ quality assurance standards.

However, in order to grow our business, improve productivity by shortening lead time used during for precision machining processes. We determined that introducing multitasking machines would allow us to consolidate processes, reduce setup changes and related tasks, and eliminate accuracy variations during setup.

Given these circumstances, what made you choose Okuma?

Among the available options, we chose the MULTUS B300Ⅱ (sub-spindle specification) for its high level of fundamental performance and compatibility with workpiece sizes.

The main decisive factor for choosing the machine was its high rigidity. This was an essential requirement for machining difficult-to-cut materials with high accuracy and speed.

Another key factor was the Thermo-Friendly Concept, a thermal displacement control technology that ensures stable machining dimensions. Although we operate using a two-shift operation schedule to keep utilization rates of machinery as high as possible, machine operations stop between 4:00 a.m. to 8:00 a.m. due to an opening between shifts. However, the MULTUS B300Ⅱ is capable of maintaining stable machining accuracy even after a cold start at the beginning of the day shift. This applies even during seasons when outside temperatures are extreme. When machining difficult-to-cut materials, cutting tools are subjected to high loads, resulting in quicker replacement cycles. One superb feature of the machine is that tool life for each indivudual tool can be managed on the OSP system.

Additionally, we had experience of using Okuma’s NC lathes, so we were confident that it would not be diffficult to learn how to program and operate an Okuma multitasking machine.

All machining processes can be completed with a single multitasking machine, resulting in approximately 30% improvement in productivity.

Both high quality and high productivity can be achieved while reducing labor.

Now that you have installed the MULTUS B300Ⅱ (sub-spindle spec), how would you rate its productivity and ease of use?

When processes are divided between a NC lathe and a machining center, significant time and effort are required for tasks such as dimensional inspection, setup changes, and workpiece cleaning. With the MULTUS B300Ⅱ (sub-spindle specification), parts that previously required four processes on two separate machines can now be completed in just two processes on a single machine due to the abiltiy to transfer workpieces between spindles. This has eliminated the need to handle work-in-progress workpieces between machines and has improved the overall production flow.

In addition, because there is minimal phase error during transfer, positioning jigs are no longer necessary. Also, issues that occurred during setup changes—such as scratches, dents, and the need to remachine due to size errors—have been drastically reduced. As a result, we have been able to significantly reduce tasks that were required between processes, resulting in a productivity improvement of approximately 30%. All this is done while maintaining micron-level machining quality. Even when machining complex parts that require various cutting and drilling operations, the MULTUS can be left unattended for approximately 30 to 60 minutes. During that time, operators can focus on preparing for the next process or conduct quality checks, which helps reduce the workload for operators managing multiple machines.

There was a motor shaft job that our competitors had refused because they could not meet its strict accuracy requirements. However, we took the job and were able to succesfully meet the various tolerances that were required for the workpiece.

In addition, the MULTUS B300Ⅱ (sub-spindle specification) features a highly rigid milling spindle, allowing it to machine tough-to-cut materials such as Inconel and titanium alloys with ease. Even at high spindle speeds. The machine also offers exceptional repeatability, enabling stable machining of precision components with tight tolerances—such as medical device parts—with dimensional accuracy in the 10-micron range.

Thank you very much.

KINREI MACHINERY CO., LTD.

We have achieved lead time reduction and space savings by integrating the machining processes of core components, which were previously handled using a lathe and external robot.

Please share why you decided to install a Multitasking Machine + Built-in Robot.

We are a manufacturer of wire stranding machines (bunchers), which are used to produce cables and wire harnesses for automobiles, aircraft, mobile devices, and medical equipment. Our machines are delivered to numerous customers, including those in over 20 countries worldwide.

All core components of the bunchers are manufactured in-house. One such component is the guide wheel, a pulley used to feed metal wire.

Its V-groove must be machined with high precision in order to smoothly feed ultra-fine metal wires—which are thinner than a human hair—at high speeds.

Until now, machining the guide wheel required five steps: two performed by an automated system consisting of an NC lathe and external robot, followed by drilling and finishing processes.

Setup changes were both labor and time intensive, while the safety fences consumed valuable floor space. Reducing lead time and achieving space efficiency had been ongoing challenges.

At that time, Okuma proposed consolidating several machining processes into one machine using the MULTUS B300Ⅱ ARMROID, a multitasking machine with a built-in robot.

Given these circumstances, what made you choose Okuma?

We have used many Okuma machines. We actually already have two multitasking machines which we have been using for some time now: the MULTUS B300 and the MULTUS U4000.

Given the situation, the proposal to consolidate several processes—previously performed with multiple machines and material handling equipment—into a single machine was very appealing, as it offered significant reductions in lead time and space usage.

What made the MULTUS B300Ⅱ ARMROID especially attractive was its built-in robot arm. Compared to our previous methods of machining, this machine would allow us to increase productivity while only requiring minimum space to install the machine and mobile workpiece stocker. In addition, the ability to ensure operator safety without installing safety fences made us feel this machine would be the perfect solution to the challenges we were facing.

However, we were unsure whether a single MULTUS B300Ⅱ ARMROID could ensure the required machining accuracy for the V-groove of the guide wheels.

Trial cuts revealed that chips scattered within the machining chamber negatively affected the groove’s machining quality.

In response, we collaborated with Okuma to develop a solution. Okuma modified the jaw shape, while we revised some of the guide wheel’s machining process. These adjustments successfully reduced the effects caused by chip scattering and allowed us to overcome this problem.

Lead time has been significantly shortened by merging five processes (which were done across two machines) into two processes (that can be done on one machine)

Now that you have installed the MULTUS B300Ⅱ ARMROID, how would you rate their productivity and ease of use?

Previously, machining of guide wheels required five separate processes, involving considerable time and effort for attaching, detaching, and transferring workpieces during each setup change.

With the introduction of the MULTUS B300Ⅱ ARMROID, operators simply load the workpieces into the mobile work stocker (a 10-station elevating multi-level worktable) attached to the machine. From there, the machine handles the entire operation, completing everthing in just two processes.

As a result, lead time has been drastically reduced and the extra time can now be used for program creation and setup for the next machining task. This has contributed to improving overall productivity.

The machining chamber contains two spindles (main and sub), a turret, a robot, and various structural components, making it difficult to track all movements and perform comprehensive interference checks.

However, by using the collision avoidance system after creating the program, interference can be checked visually and allows automatic operation to be done with confidence.

To increase productivity with limited personnel, we plan to perform short-cycle turning and small-lot machining manually during the day, while using the MULTUS B300Ⅱ + ARMROID for unmanned nighttime operation of medium-lot, time-intensive complex machining. We are actively working toward realizing this vision as soon as possible.

Thank you very much.

Please share why you decided to install a 5-axis Machining center