- HOME

- Technology & Solutions Solutions by industry

- Automotive industry

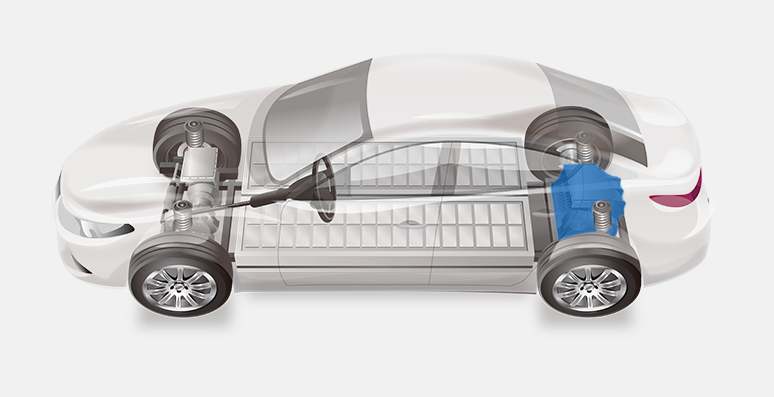

- Reducer component Motor shaft (e-Axle)

e-AxleReducer component

Motor shaft

Component inserted into motor rotor

Material: S45C

Shortening non-operation time with automatic setup change

POINT 01

- The NC tooling stand + wide range sizer and NC tailstock makes it easy for anyone to operate, increasing operating rate

-

- The Z-direction position and measuring diameter of the sizer can be flexibly changed by NC commands

The dimensions of the outer diameters of all workpieces can be monitored and controlled - The support position and thrust on the tailstock side can be flexibly changed using only NC commands

Workpieces with different lengths and weights can be handled

- The Z-direction position and measuring diameter of the sizer can be flexibly changed by NC commands

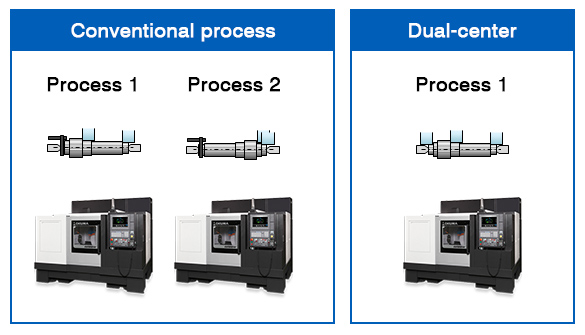

POINT 02

- Workpiece load/unload is easier with the dual-center drive specification

-

- The whole area of the outer diameter can be machined without chuck change with the dual-center drive specification

The workload on workers is reduced with no need to turn over workpieces - Two processes are integrated and handled on one machine, allowing operator to reduce the number of machines required in the factory and reducing power consumption

- The whole area of the outer diameter can be machined without chuck change with the dual-center drive specification