PRODUCTS

The best monozukuri* practices balance

high-accuracy machining and workability

*Craftsmanship-based manufacturing

-

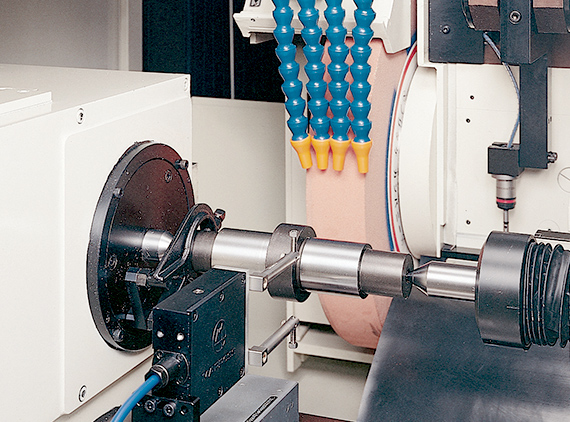

Plain type

Plain type-

-

Smaller machine space achieved with use of wheelhead traverse structure

A wheelhead traverse structure requires a stronger foundation than a table traverse structure. Okuma’s high-rigidity technology meets the conditions needed for a wheelhead traverse structure to achieve a compact body.

-

-

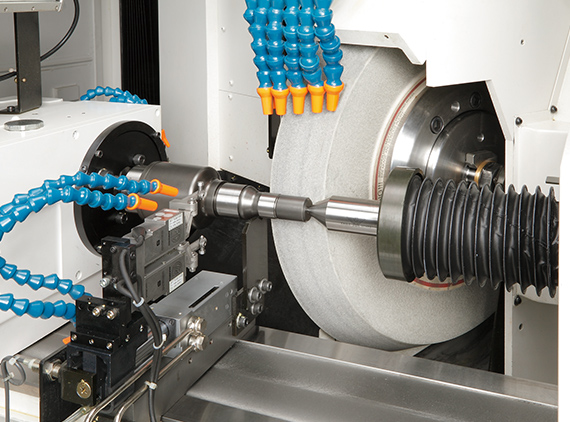

Angle type

Angle type-

-

Superior user-friendly design supports automation

The upper portion of the front door can accommodate various loader positions. Line flexibility from the space-saving design also contributes to greater automation.

-

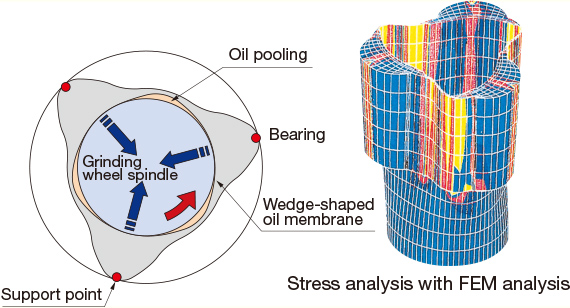

- Hydrodynamic bearing provides for heavy-duty and highly accurate grinding—with shorter cycle times

-

Non-round plain bearing wheel spindle with a dynamic pressure structure supports the wheel spindle with wedge-shaped oil film pressure that is generated by wheel spindle rotation. Retention strength is a powerful 1 t, in addition to which wheel rotation accuracy is kept to within 0.01 µm for a good balance of high accuracy grinding even in heavy-duty cutting. Also, because the wheel spindle has no metal contact, its original performance is maintained semi-permanently.

-

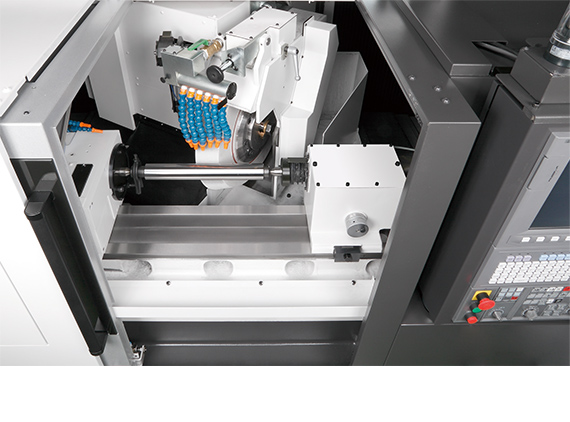

- High machining efficiency maintained

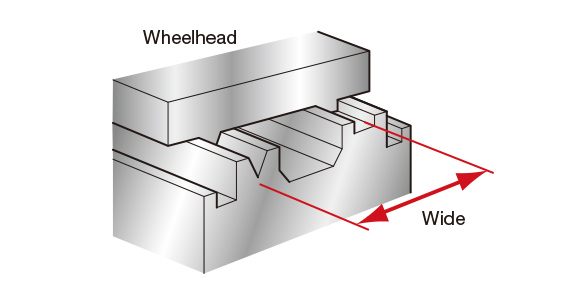

with wide V—Flat guideway - A widened V—Flat guideway system is used that expands the span between the V and Flat guideways beneath the saddle. Higher workpiece support rigidity enables grinding with full power of 7.5 kW (optional 15 kW). The grinding load on the wheelhead during heavy-duty grinding is supported by wide V—Flat guideway for high machining efficiency.

- High machining efficiency maintained

-

- Machining time is shortened with high

speed feed at the top level in the class - Structure with unrivaled high following characteristics gives high feed speeds of ø30 m/min on the X axis and 20 m/min on the Z axis. Shorter non-cutting times contribute to improved machining efficiency.

-

- X-axis feedrate: ø30 m/min

- Z-axis feedrate: 20 m/min

- Machining time is shortened with high

Highlighted Specs

| Item | Unit | GP14/15W GA14/15W |

GP25/26W GA25/26W |

|---|---|---|---|

| Swing over table | ømm (øin) | 330 (12.99) | 330 (12.99) |

| Distance between centers | mm (in) | 250 (9.84) | 400, 650 (15.75, 25.59) |

| Wheel size (OD × width) |

mm (in) | ø405 × 75 / ø510 × 75 (ø15.94 × 2.95 / ø20.08 × 2.95) |

ø510 × 75 / ø610 × 75 (ø20.08 × 2.95 / ø24.02 × 2.95) |

| Wheel peripheral speed | m/sec | 45 | 45 |

| Wheel motor | kW (hp) | 5.5 (7.5) | 7.5 (10) |

| Machine size (W × D × H) |

mm (in) | 1,550 × 2,734 × 2,150 (61.02 × 107.64 × 84.65) |

2,030, 2,510 × 2,932 × 2,218 (79.92, 98.82 × 115.43 × 87.32) |