- HOME

- Technology & Solutions Solutions by industry

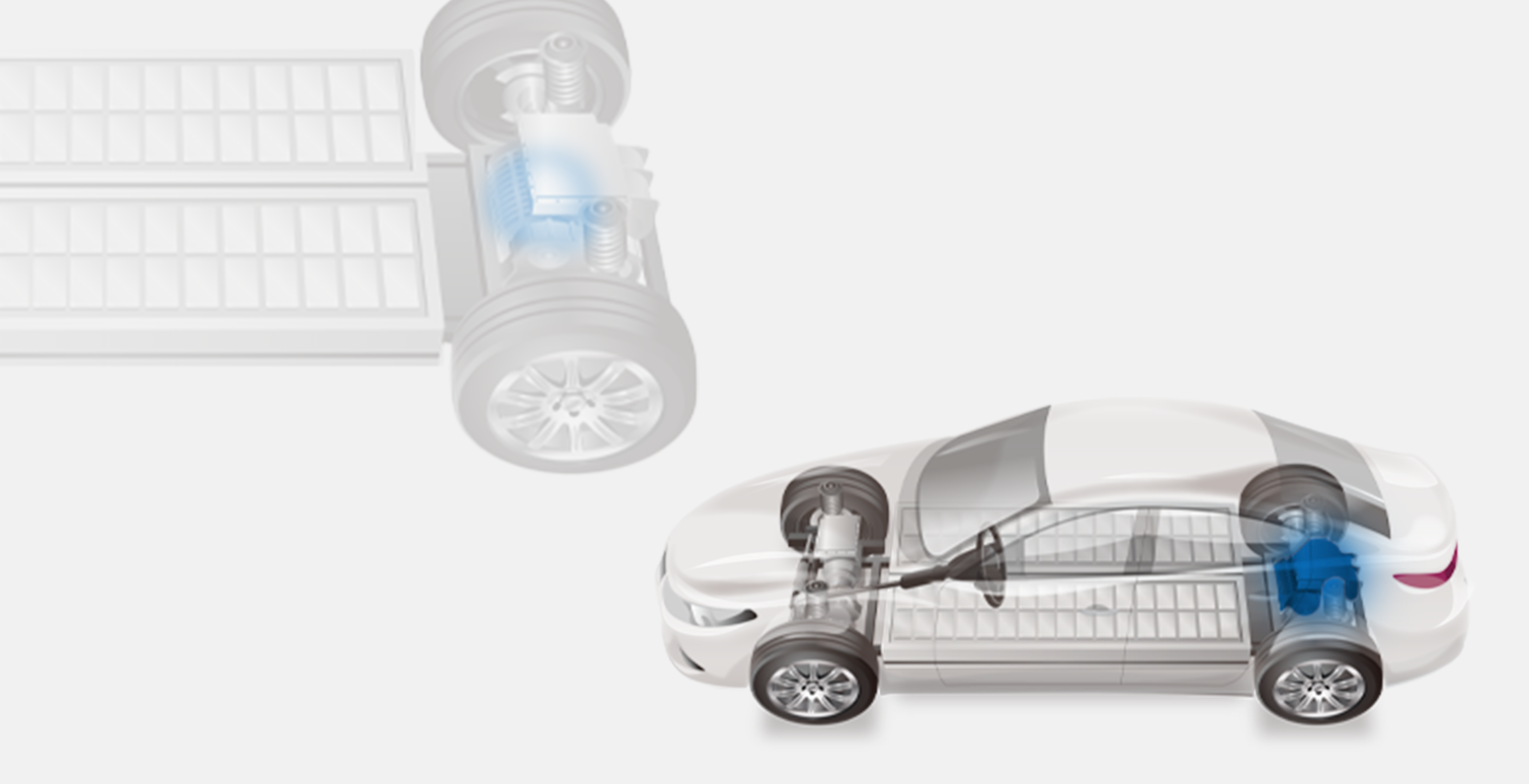

- Automotive industry

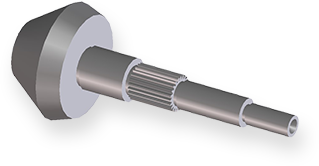

- Power transmission component Drive pinion (Drive, transmission, and steering-related component)

Drive, transmission, and steering-related componentPower transmission component

Drive pinion

Component that transmits torque to the ring gear and keeps rotation direction at a right-angle (for FR/4WD vehicles)

Material: SCM418H

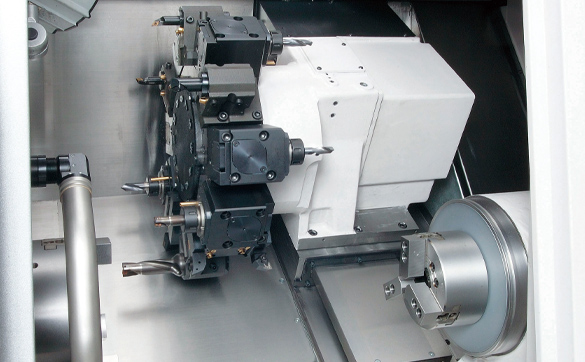

Machining is completed without chuck change by using a hydraulic quill tailstock and face driver

POINT 01

- Even tapered workpieces that are difficult to chuck can be machined in a stable manner

-

- The face driver and hydraulic quill tailstock secure workpieces firmly, enabling machining to be completed without chuck change

- Stable accuracy is secured with two-center support machining

Provide various proposals

- A variety of specifications are offered to enable various types of machining

-

- Y-axis function: Versatile milling is possible with wide Y-axis travel range

- W-axis specs: Process-intensive machining for front and back side of workpiece can be done on one machine with sub spindle specification

- Steady rest: Stable machining of long workpieces

- In-process gauging: Automated measurement and compensation of workpiece dimensions using an in-process gauge