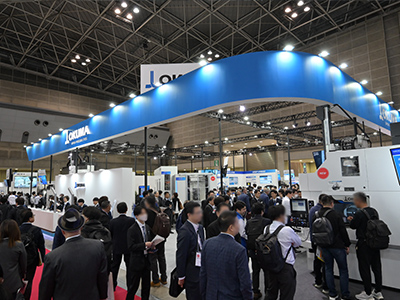

Thank you for coming to our booth at “JIMTOF 2024”

PICK UP

To solve issues such as labor shortages and reduction of environmental burdens, we propose continuous productivity improvements at your site through automation, manpower-saving, and process-intensive machining in which 5-axis and multitasking machines play a major role.

- Automation

Solution - Process-intensive

Solution

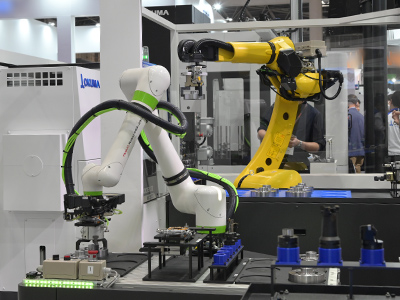

Automation solutions that machine operators can utilize effectively and a

variety of automation lineups tailored to your issues and production types

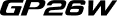

Compact automated cells

- We want to introduce automation that requires minimal space

- We want to be able to use machines by switching them between automatic and manual operation

- We want to use robots easily without needing expertise in robotics

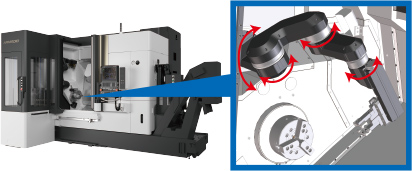

Next-Generation Robot System

This articulated robot is “built-in” to the machining chamber.

Automation can be achieved with minimal space.

- We want to automate machines flexibly according to production

- We want to be able to use machines by switching them between automatic and manual operation

- We want to use robots easily without needing expertise in robotics

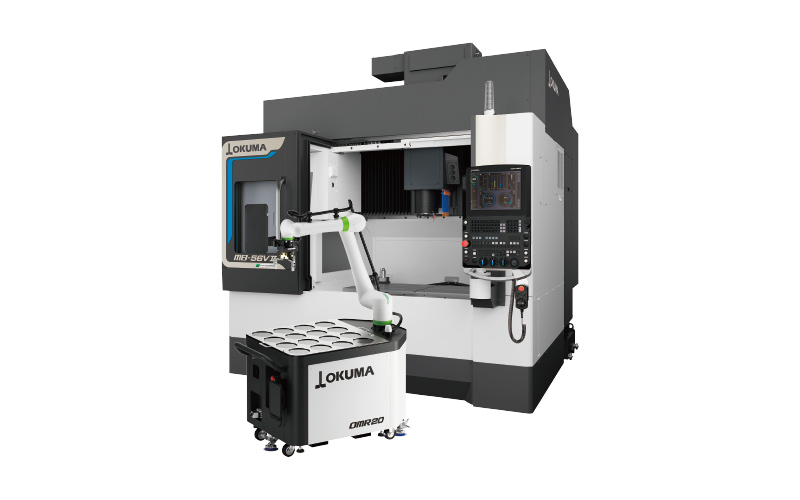

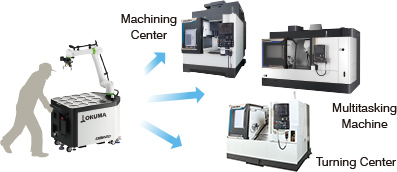

Mobile Collaborative Robot

You can easily move the stocker equipped with this robot.

This is a mobile Collaborative Robot that automates workpiece loading/unloading for necessary machines according to how busy production is.

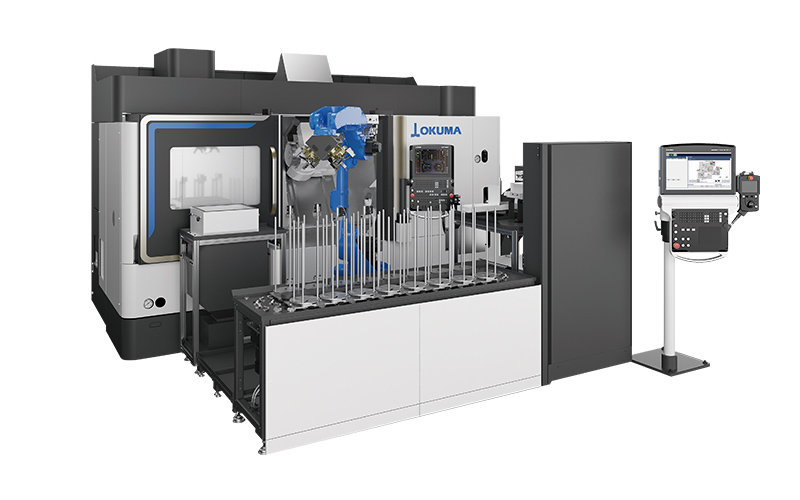

Automated cell including workpiece transport and peripheral devices

- We want to introduce full-fledged automation easily

- We want to operate a manufacturing cell with similar operability to machine tools

- We want to use robots easily without needing expertise in robotics

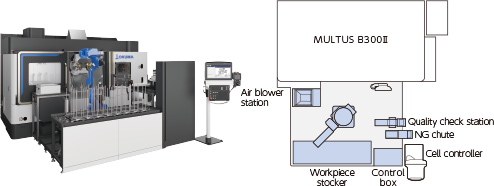

Robot manufacturing cell suitable for high-mix production

A robot manufacturing cell that allows advance preparation with a digital twin. Even in the event of an emergency stop, it provides guidance for the restart procedure after eliminating the fault to allow you to restart production without hesitation.

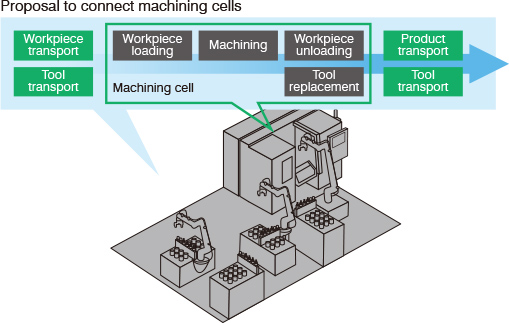

Auto transport between cells

- We want to reduce the burden of logistics

- We want to operate for long periods with a small group

- We want to concentrate machine tool control and product control in one location

We propose automation of your plant by connecting machining cells with the introduction of AGVs (automatic guided vehicles)

Machining solutions that are easy to use even for people

without much experience

5-axis and multitasking machines that maximize productivity

MachineProcess integration of turning and milling with high accuracy

Multitasking Machines

Space-saving models with excellent operability

ARMROID

(with a built-in robot) is exhibited

smarTwinCELL

(smart machining cell) is exhibited

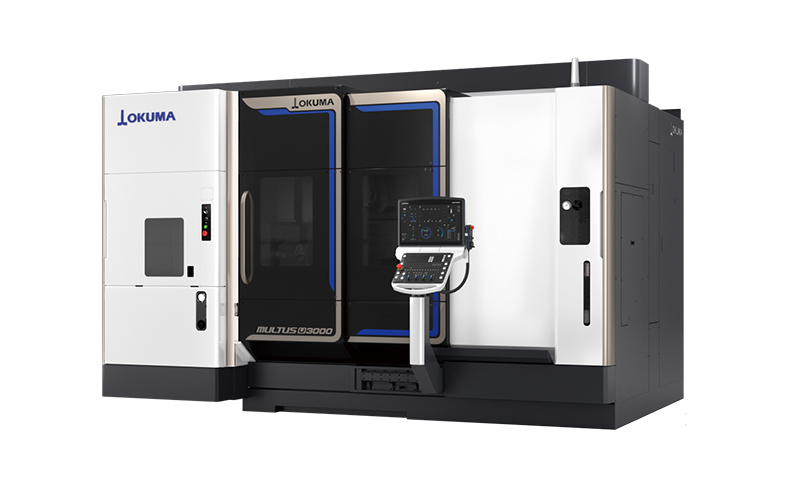

Multitasking Machine

A model with a lower turret* and high productivity

*2S type

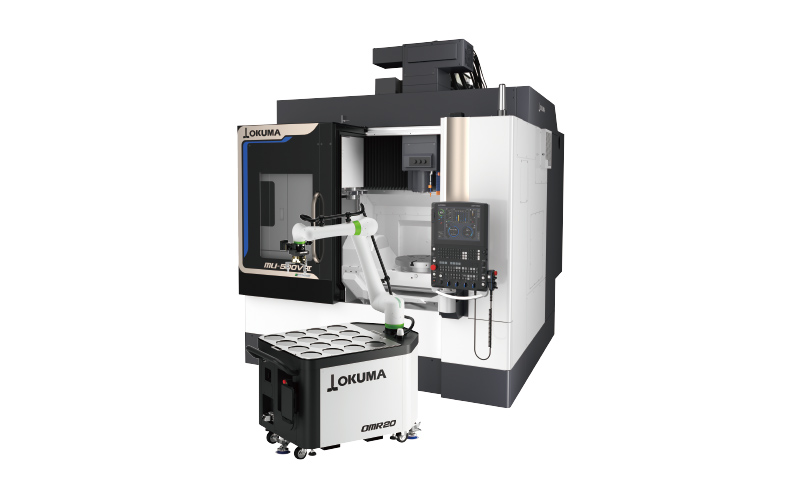

High-accuracy 5-axis machining center that is space-saving and easy to use

5-Axis Vertical Machining Center

A compact 5-axis machining center that requires the same compact space as a vertical machining center

Compare the size with a vertical

machining center

Will be exhibited with mobile collaborative robot OMR

High productivity realized by 5-axis and multi-sided machining

5-Axis Vertical Machining Center

Large work envelope and comfortable work space

An elevating 2-level, 7-pallet APC is exhibited

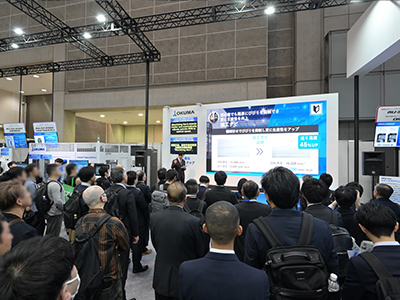

PRESENTATION

-

- 15-axis and multitasking machines

- Multitasking machines and 5-axis machining centers that are easy to use and improve productivity

-

- 2Automation

- Automation that anyone can use and that supports improvement of factory production

-

- 3New Product Introduction

- New Horizontal Machining Center solves manpower shortage with new standards of manufacturing automation

EXHIBITION MODELS

Click the number on the map to see detailed information about exhibited machine.

-

1

5-Axis Vertical Machining CenterMU-500V Ⅲ+

Mobile Collaborative RobotOMR20 -

2

5-Axis Vertical Machining CenterMU-6300VElevating 2-Level, 7-pallet APC

-

3

Multitasking Machine+

Built-in RobotMULTUS B250Ⅱ ARMROID -

4

Multitasking Machine +

Smart Manufacturing CellMULTUS B300Ⅱ+smarTwinCELL -

5

Multitasking MachineMULTUS U3000

-

6

Vertical Machining CenterMB-46V Ⅱ

-

7

Vertical Machining CenterMB-56V Ⅱ+

Mobile Collaborative RobotOMR20 -

8

Vertical Machining CenterMB-80V

-

9

Horizontal Machining CenterMS-320H

-

10

Horizontal Machining CenterMA-4000H

-

11

Double-Column Machining CenterMCR-Swith a swivel attachment head

-

12

1-Saddle Turning CenterLB3000 EX Ⅲ(M)with a turret ATC + AGV

-

13

1-Saddle Turning CenterLB3000 EX Ⅲ(MYW)

-

14

CNC Cylindrical GrinderGP26W

5-Axis Machining Centers /

Multitasking Machines

Machining Centers

Turning Centers

Grinder

Note: Exhibited machines and booth layout are subject to change without notice.

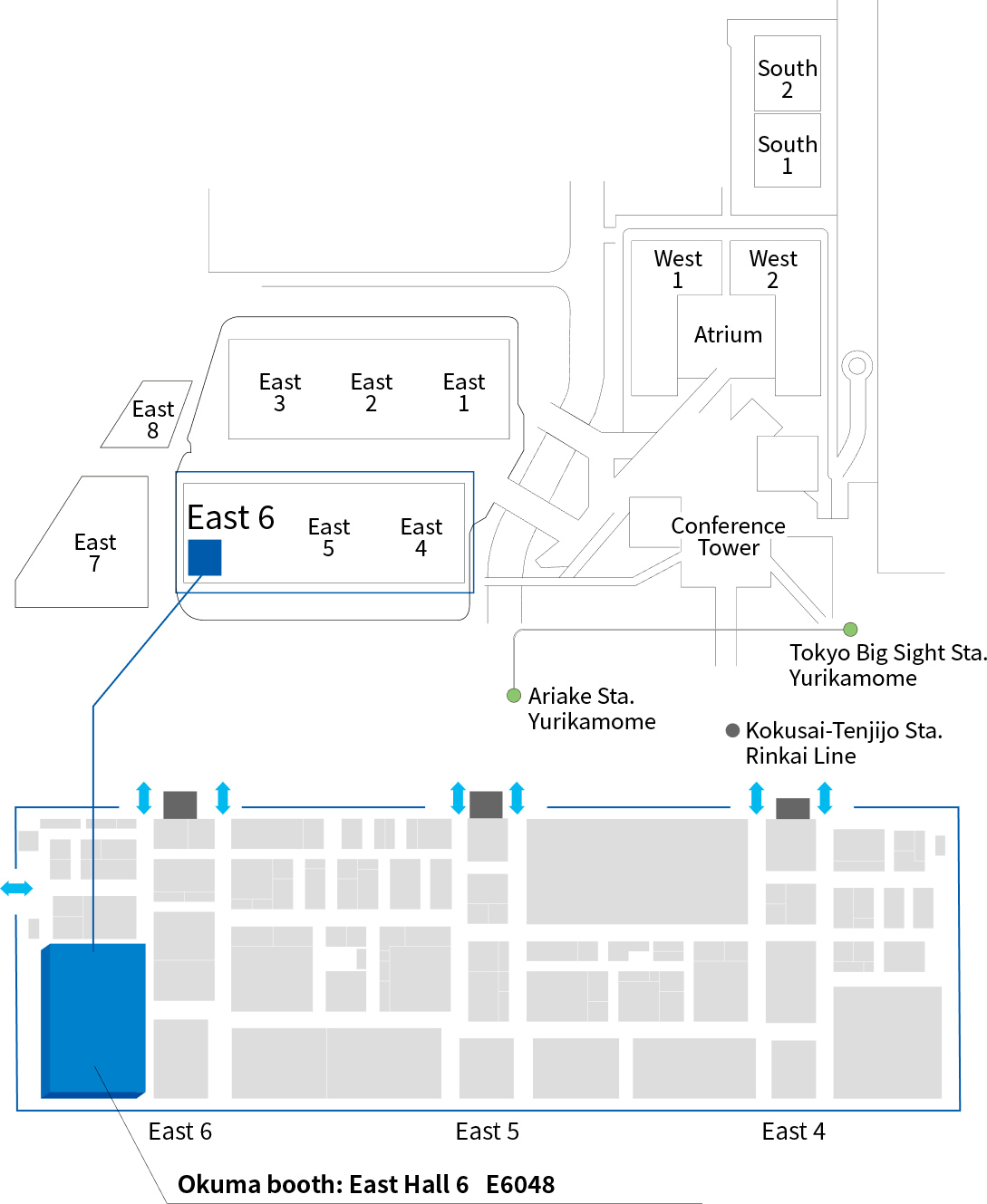

VENUE MAP

- VENUE

- Tokyo Big Sight (Tokyo International Exhibition Center) East Hall 6 E6038

- Open

- November 5 (Tue.) - November 10 (Sun.), 2024

+

+

+

+