PRODUCTS

- Achieve ideal balance for 1-2 processes

-

- Highly efficient machining with spindles with same capacity on left and right

- Left and right spindles equipped with high accuracy integral motor/spindles make part transfer possible during spindle operation with synchronized C axis control.

-

LT2000 EX LT3000 EX Spindle motor 11.5/7.5 kW

(5 min/cont)22/15 kW

(30 min/cont)Bar dia Standard spindle ø51mm ø65mm*2 Big-Bore spindle ø65mm*1 ø80mm - *1. Left spindle only

- *2. Up to ø69 mm is possible with 10-inch chuck.

- Note: The chuck/cylinder used may limit machinable bar diameters.

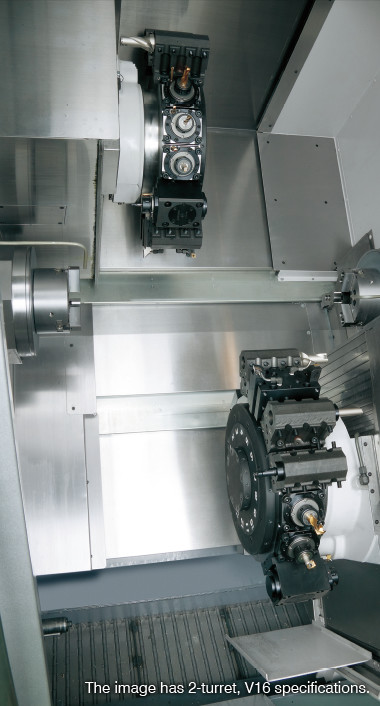

- Turrets with the same upper and lower capacity enable full process-intensive machining

- V16 turrets are used on both top and bottom to handle complex shape, multi-process, high mix production. Setup change time can be shortened with permanent tool sets.

-

LT2000 EX LT3000 EX Milling-tool spindle motor 5.5/3.7 kW

(2 min/cont)7.1/4.1 kW

(25 min/cont)Rapid traverse X axis: 30 m/min, Z axis: 40 m/min

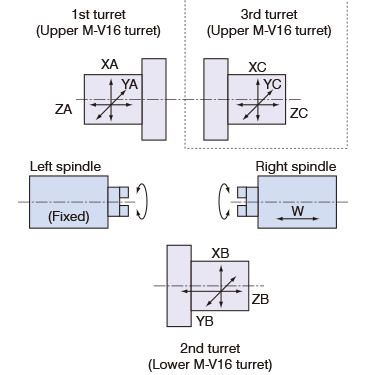

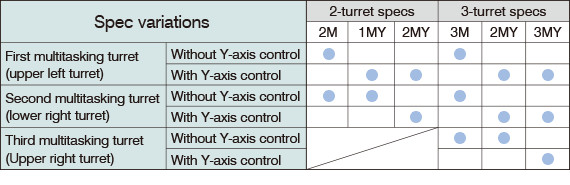

- Achieve the best production system with our abundant lineup

- Achieve even greater productivity and process-intensive machining by selecting specifications matched to use, such as simultaneous machining with 3 upper/lower turrets or simultaneous upper/lower Y-axis machining.

-

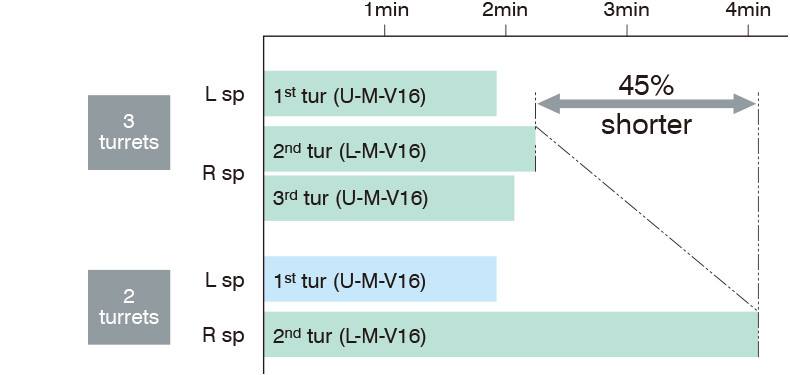

- Minimize takt time with third turret (Optional)

- Well-balanced cycle times achieved with simultaneous machining using upper left and right turrets and lower turret. Cycle times can be significantly shortened.

-

- Y-axis specifications (Optional) added on all turrets

- Simultaneous upper/lower Y-axis machining possible.

-

LT2000 EX LT3000 EX Y-axis travel 95 mm

YA, YC: +50 to -45

YB: +45 to -50125 mm

YA, YC: +70 to -55

YB: +55 to -70

Highlighted Specs

| Item | Unit | LT2000 EX | LT3000 EX |

|---|---|---|---|

| Standard chuck size | in | 6 | 8 |

| Max turning dia | ømm (øin) | 210 (8.27) | 350 (13.78) |

| Max work length | mm (in) | 130 (5.12) | 200 (7.87) |

| Spindle speed | min-1 | 6,000 | 5,000 |

| Turret | U/L: M-V16 | U/L: M-V16 | |

| Motor | kW (hp) | L/R: 11.5/7.5 (5 min/cont) (15/10) | L/R: 22/15 (30 min/cont) (30/20) |

| Machine size (W × D × H) |

mm (in) | 3,745 × 2,464 × 2,285 (147.44 × 97.01 × 89.96) |

4,504 × 2,750 × 2,650 (177.32 × 108.27 × 104.33) |

| Spec extension | MY, 3T | MY, 3T |

M: Milling, Y: Y-axis, 3T: 3-turret