- HOME

- NEWSROOM

NEWSROOM

26 Jul 2022

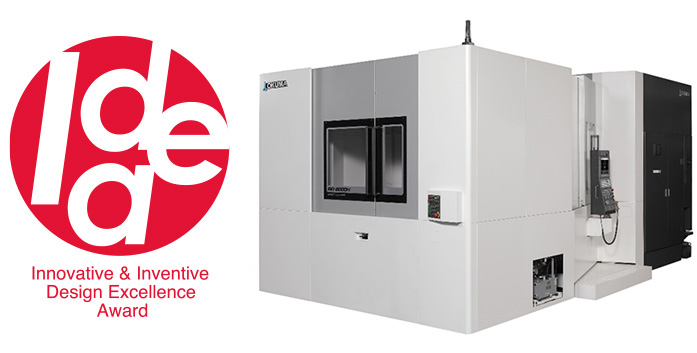

MA-8000H Horizontal Machining Center

Recipient of the Nippon Brand Award

in the Nikkan Kogyo Shimbun's 52nd Industrial Machinery Design Awards

MA-8000H Horizontal Machining Center for reducing CO2 emissions and achieving highly efficient production.

Okuma's MA-8000H Horizontal Machining Center was awarded the Nippon Brand Award; an award presented at the 52nd Innovative & Inventive Design Excellence Award (IDEA) sponsored by Nikkan Kogyo Shimbun.

The MA-8000H is equipped with energy-saving technology that allows a machine tool to autonomously contribute to decarbonization. It is a horizontal machining center that achieves sustainability along with high accuracy and high productivity. Energy-saving technologies such as the Thermo-Friendly Concept and ECO suite plus enable the machine to maintain high accuracy while commiting to decarbonization. These are standard features and reduce carbon dioxide emissions during production.

Features such as the sludgeless tank (which reduces the frequency of tank cleaning) and AI machining diagnostics (which prevents tool breakage) are provided to enable long runs of continuous operation. Features like these also allow the machine to flexibly change and adjust to automation configurations and labor saving.

At Okuma, we are committed to providing solutions to the social issues that a variety of industries are facing within their manufacturing sites, including the semiconductor manufacturing equipment, energy, and automotive sectors. We are also committed in contributing to making dramatic improvements in labor productivity.

- Other recipients of the Machine Design Award

-

-

50th Awards (2020)

MCR-S (Super) Double-Column Machining Center

MB-80V Vertical Machining Center - The 49th (2019) Grand Prize (Ministry of Economy, Trade and Industry Award) for the ARMROID Next-Generation Robot System

- The 48th (2018) Grand Prize (Ministry of Economy, Trade and Industry Award) for the MU-S600V 5-Axis Vertical Machining Center

- The 45th (2015) Grand Prize (Ministry of Economy, Trade and Industry Award) for the ECO suite Next-Generation Energy-Saving System

-

The 44th (2014) Japan Machine Tool Manufacturers Association Award

for the MCR-C Double-Column Machining Center [5-Face Machining] -

The 43rd (2013) Judging Committee Special Award

for the MU-10000H 5-Axis Horizontal Machining Center - The 42nd (2012) Grand Prize (Ministry of Economy, Trade and Industry Award) for the MULTUS B300II Intelligent Multitasking Machine

- The 40th (2010) Judging Committee Special Award for the VTR-A Series Double Column Turning Centers

-

The 38th (2008) Japan Machine Tool Manufacturers Association Award

for the MULTUS B200 Intelligent Multitasking Machine - The 35th (2005) Japan Machine Tool Manufacturers Association Award for the 2SP-150H 2-Spindle Horizontal CNC Lathe

-

The 34th (2004) Judging Committee Special Award

for the UNIVERSAL CENTER MU-400VA 5-Axis Vertical Machining Center

-

50th Awards (2020)