- The “ECO suite” Next-Generation Energy-Saving System Wins

Excellence Award / Minister of Economy, Trade and Industry Award

at Nikkan Kogyo Shimbun’s 45th Machine Design Awards - 07 August 2015

Okuma’s ECO suite next-generation energy-saving system has won the Excellence Award/Minister of Economy, Trade and Industry Award at the 45th Machine Design Awards sponsored by the Nikkan Kogyo Business & Technology Daily News.

The ECO suite is a next-generation system that saves energy by reducing the power consumption during both machine operating and waiting times.

It consists of ECO Idling, the world’s first application to stop machine tool idling; the ECO Power Monitor that displays power consumption in real time with visual graphics; and ECO Hydraulics and ECO Operation to optimize energy savings in accordance with the machine shop environment. It is an advanced energy-saving technology that dramatically cuts power consumption while high machining accuracy is maintained.

→Click here for information on the ECO suite

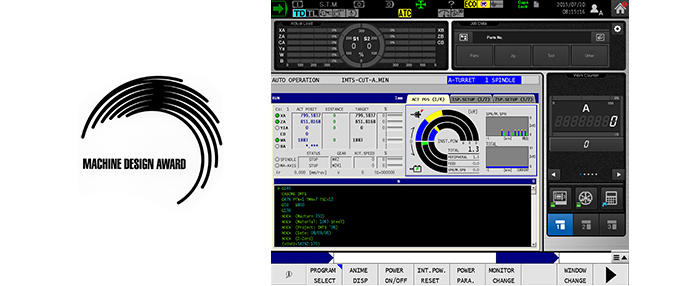

Example of ECO Power Monitor display

Okuma’s Machine Design Award history

- MCR-C Double-Column Machining Center for 5-Sided Applications

Japan Machine Tool Manufacturers Award, 44th Machine Design Awards (2014) - UNIVERSAL CENTER MU-10000H 5-axis horizontal machining center

Jury’s Special Award, 43rd Machine Design Awards (2013) - MULTUS B300II intelligent multitasking machine

Excellence Award/Minister of Economy, Trade and Industry Award, 42nd Machine Design Awards (2012) - VTR-A Series double column machining centers

Jury's Special Award at the 40th Machine Design Awards (2010) - MULTUS B200 intelligent multitasking machine

Japan Machine Tool Builders Association Award, 38th Machine Design Awards (2008) - 2SP-150H parallel 2-spindle CNC lathe

Japan Machine Tool Manufacturers Award, 35th Machine Design Awards (2005) - UNIVERSAL CENTER MU-400VA 5-axis vertical machining center

Jury’s Special Award, 34th Machine Design Awards (2004)