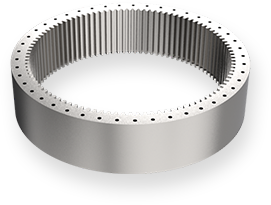

Highly efficient machining of large gear components

POINT 01

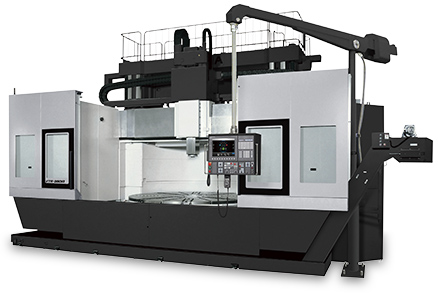

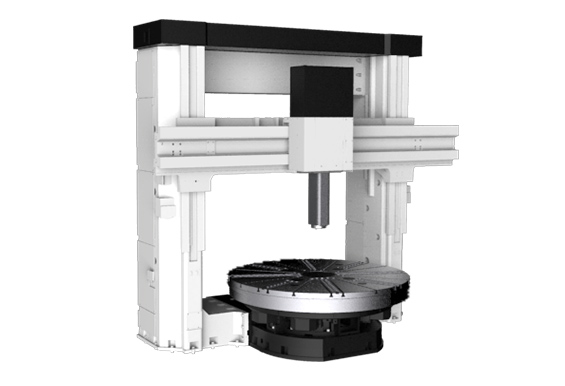

- Double-column multitasking machine VTR-350AEfficient machining of large-diameter components using the highly rigid double-column structure

-

- Multitasking double-column machine with high rigidity

- Max machining diameter: ø3,500 mm

Max turning height: 1,600 mm - Turning: 10 mm2(S45C)

Milling capacity: 317cm3/min (S45C)

POINT 02

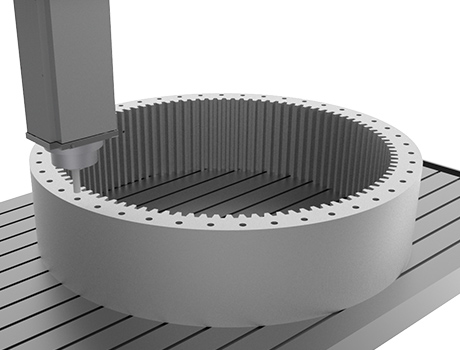

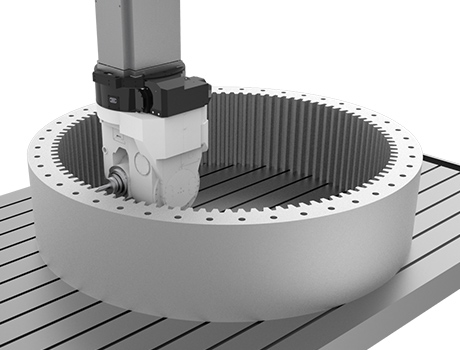

- Double-column machining center MCR-BⅤ

High-precision machining of large gear tooth surfaces using the NC-BC universal head -

- The NC-BC universal head, featuring a sub-degree indexing angle, enables precise angular positioning for tooth surface machining.

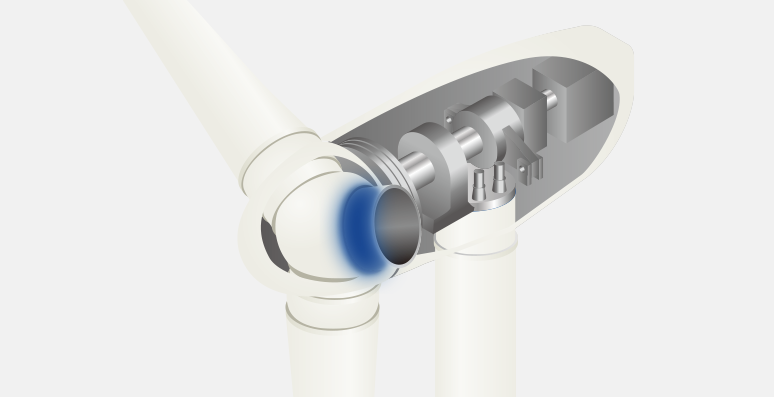

POINT 03

- Double-column machining center MCR-BⅤ

Highly efficient top-side hole machining with a high output extension head -

- High output extension head

Max spindle output: 26 kW

Spindle torque: 1,406 N-m - With over 100 types of spindle-head attachments, one machine can handle components of any shape

- High output extension head