- HOME

- Technology & Solutions Solutions by industry

- Medical equipment industry

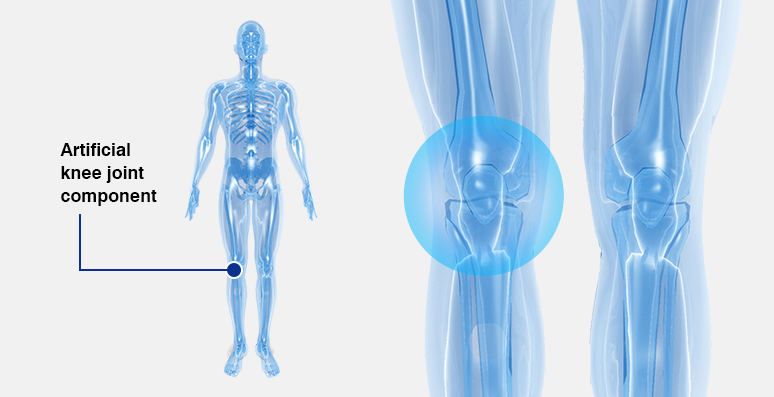

- Artificial knee joint

Minimizing boundary errors to reduce lead time for finishing process

POINT 01

- Minimizing boundary errors during indexed machining

Reducing lead time for finishing process -

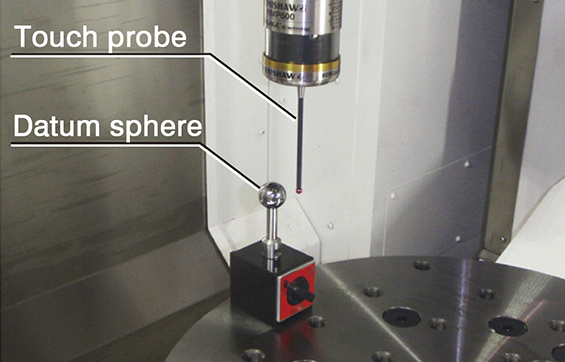

- 5-axis machining centers have a complex axis configuration, making them prone to geometric errors. These geometric errors can be easily measured and compensated using the 5-Axis Auto Tuning System Ⅱ.

- Manual tuning effort is reduced.

- Boundary errors during indexed machining are minimized.

- Actual data of boundary errors: 3μm

POINT 02

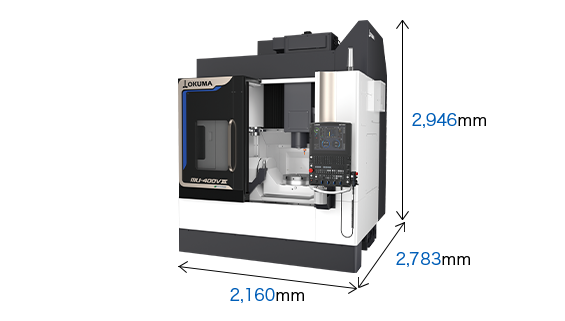

- 5-axis machining centers can be installed within the same floor space as a 3-axis vertical machining center

-

- Compact 5-axis machining centers based on the structure of a 3-axis vertical machining center.

- Good access to the table allows setup to be conducted in a comfortable position.