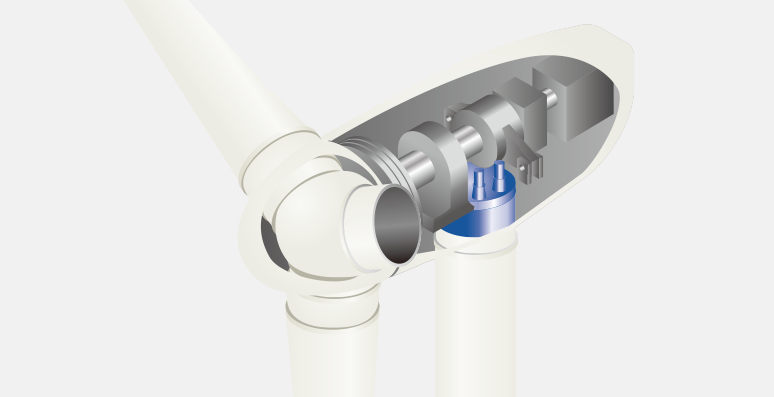

Process integration for large gear component production

POINT 01

- ProfitTurning® improves tool life and shortens machining time

-

- ProfitTurning®, which machines curved surfaces by maintaining a constant tool contact angle and evenly distributing the load, extends tool life and shortens machining time at the same time

(Utilizing HEXAGON’s CAD/CAM software: ESPRIT)

- ProfitTurning®, which machines curved surfaces by maintaining a constant tool contact angle and evenly distributing the load, extends tool life and shortens machining time at the same time

Highly efficient machining of a curved surface

POINT 02

- Highly efficient gear cutting with a formed end mill shortens production lead times

-

- Production lead time is shortened by gear cutting using a formed end mill

Gear cutting with a formed end mill

POINT 03

- Streamlined product management through high accuracy in-machine gauging

-

- Lead time is shortened by integrating diameter/hole position measurement and gear accuracy measurement using NC Gage

In-machine gauging with NC Gage