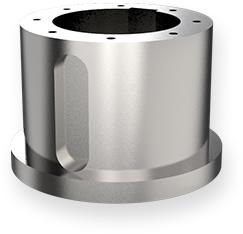

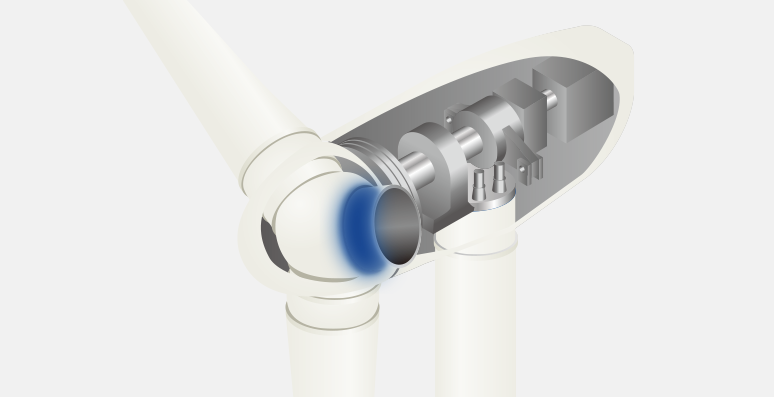

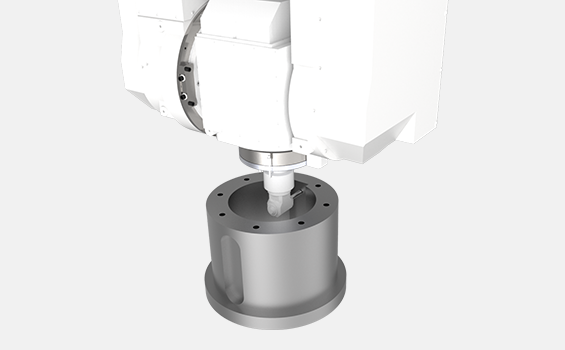

Integration of turning and side grooving processes for large diameter components

POINT 01

- High machining capacity that matches those of large lathes and machining centers

-

- Efficient machining of large components

-

Turning: 6.5 mm2 (S45C)

Milling capacity: 1,003cm3/min (S45C) -

Turning spindle max torque: 6,000 N-m

Milling tool spindle max torque: 505 N-m - Max machining diameter: ø1,200 mm

Highly efficient machining of large components (referential video featuring alternate component)

POINT 02

- Hassles during setup are minimized through the process integration of turning and milling

-

- Process integration of side milling with an angle head following turning

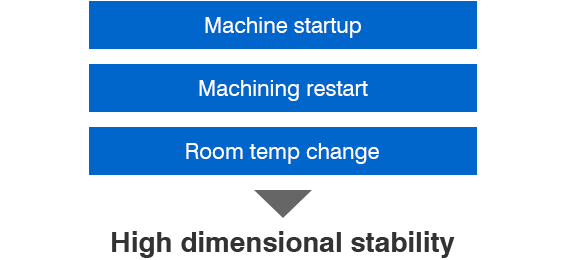

POINT 03

- Stable machining accuracy achieved through Thermo-Friendly Concept

-

- Outstanding dimensional stability ensures consistent dimensional accuracy even during continuous, long-duration machining operations

- Thermal deformation over time: less than 20 μm (actual data)