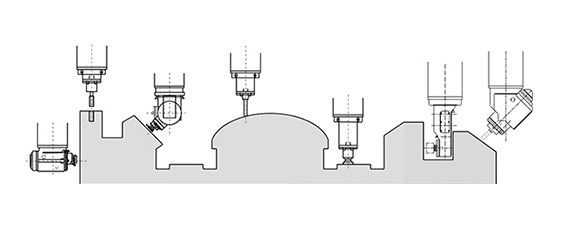

Process integration of large diameter hole drilling and side hole drilling

POINT 01

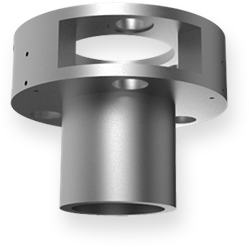

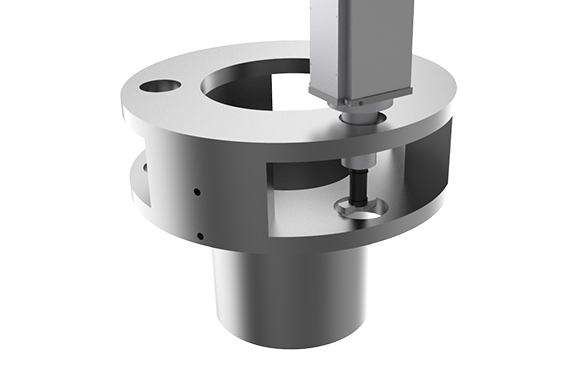

- Large diameter and inversed spot facing machining using a special head

-

- Efficient machining of large-diameter carrier holes using a special slim and long head while avoiding interference

- Helical machining with a special head and side cutter enables large-diameter inversed spot facing in the same process as carrier hole machining

Achieves large-diameter inversed spot facing with no phase shift from the carrier hole

POINT 02

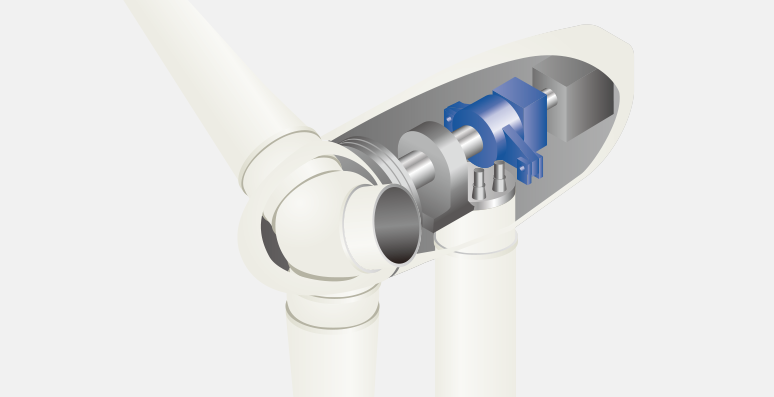

- Highly efficient drilling of outer peripheral holes

-

- Outer peripheral holes drilled with high efficiency using NC-BC universal head

- With over 100 types of spindle-head attachments, one machine can handle components of any shape

POINT 03

- Long term high accuracy is maintained

-

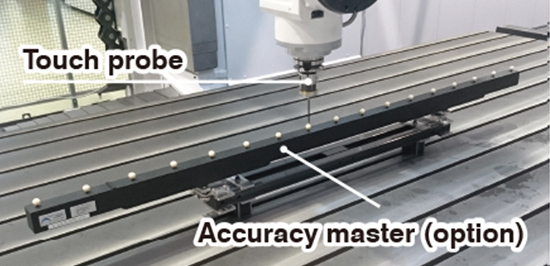

- Changes in machine accuracy are diagnosed and visualized with an accuracy stability diagnosis function

The impact that changes in room temperature has on machine accuracy is visualized - The spatial accuracy of the machine is calibrated with 3D Smart Calibration System

Regular inspections and calibrations of machine accuracy maintain high accuracy over the long term and ensure the reliability of measurement and machining processes

- Changes in machine accuracy are diagnosed and visualized with an accuracy stability diagnosis function