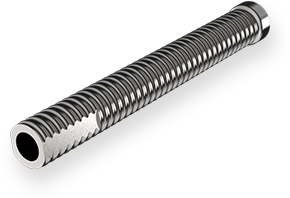

Stable machining of long nut components with deep holes

POINT 01

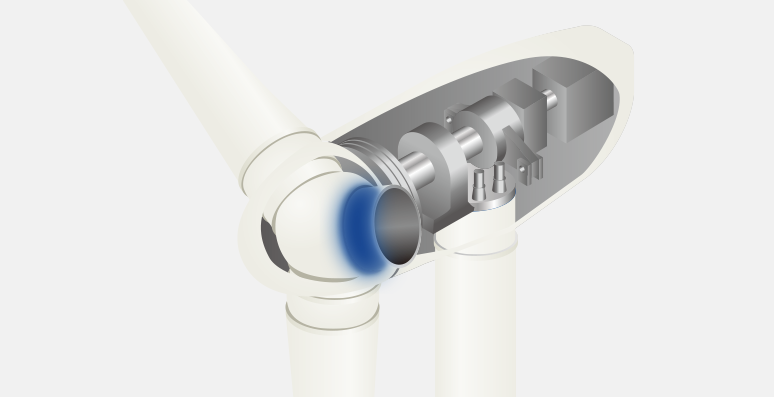

- Stable machining of long nut components using a self-centering hydraulic steady rest

-

- Components are secured with self-centering hydraulic steady rest during machining for chatter control.

- The opening/closing of the self-centering hydraulic steady rest is programmatically controlled, contributing to labor saving during the machining of long nut components.

Operation of self-centering hydraulic steady rest (referential video featuring alternate component)

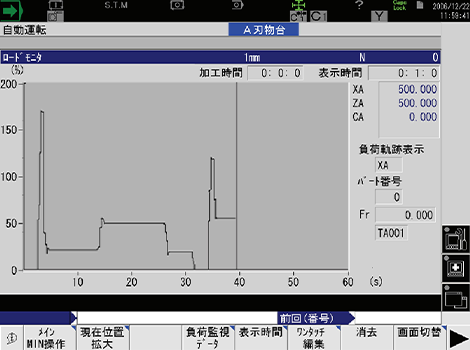

POINT 02

- Abnormalities in tool status during deep hole machining are detected by the load monitor to prevent defective products

-

- The load monitor, which tracks machining loads, triggers an alarm if preset thresholds are exceeded, thereby preventing the occurrence of defective products.

POINT 03

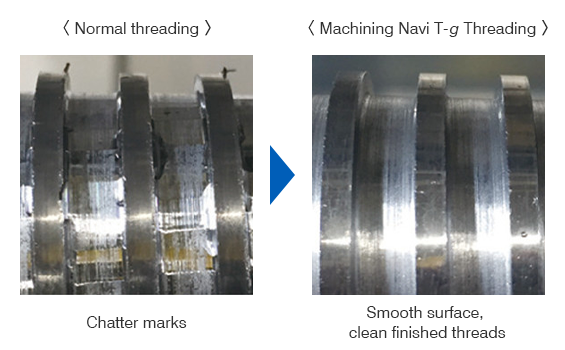

- Chatter that occurs during threading can be contolled easily and done by anyone

-

- Machining Navi T-g (Threading) optimally controls the spindle rotation speed for each pass, effectively suppressing the periodic vibrations that cause chatter.

- Enhance threading productivity while reducing tool costs at the same time